Charles R. Goulding and Preeti Sulibhavi look at the new practice of 3D printing cremation urns for the deceased.

The demand for cremation is rising in the U.S. In 2020, 56% of Americans who died were cremated, more than twice the amount of 27% from twenty years ago.

Burial costs have from 6.4% to 7.4% from five years ago. There are about 20,272 registered cemeteries in the U.S. While the U.S. is a large country with a relatively low population density, that does not mean that cemetery space is infinite. Far from it. In fact, some states it expected that the amount of cemetery space will run out based on land area, death rate and population growth. These states include California, New York, and Massachusetts.

The 3D printing of cremation urns allows loved ones to pay tribute to their deceased relatives and/or friends through custom designs and additions.

Some might choose to 3D print cremation urns in the image of their loved ones’ face in head-shaped urns as featured above. Others might opt for a more traditional urn. The fact remains that 3D printing allows families to choose more specific, personal themes and aesthetics for their loved ones’ remains. A company currently offering this service is In The Light Urns, based in California.

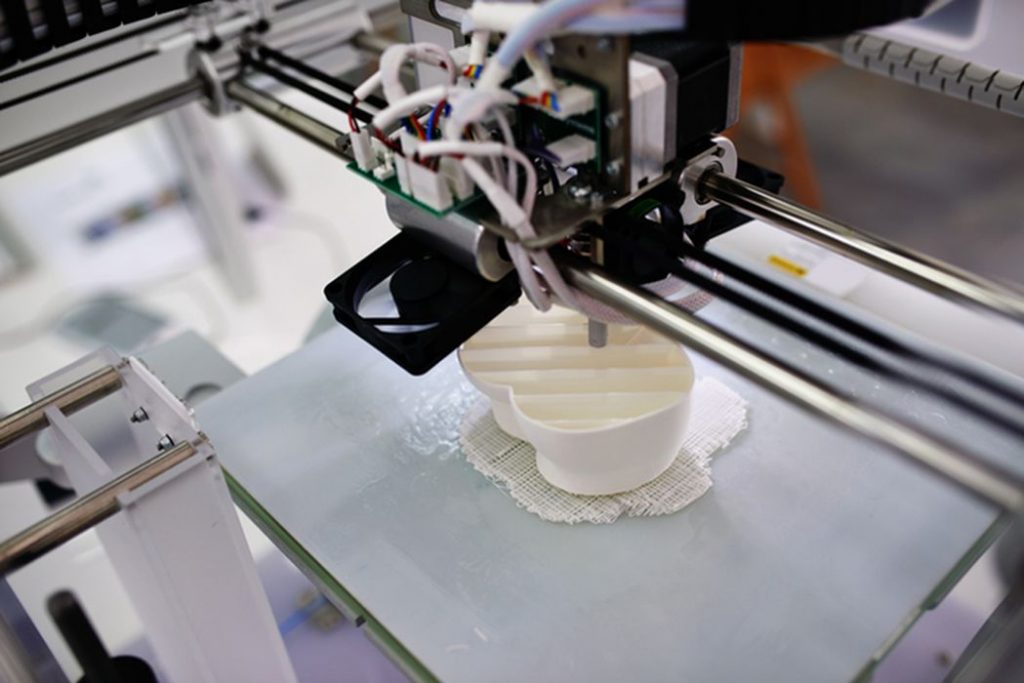

Whether it is a deceased one’s favorite car, food or even a replica of their own face/head, 3D printing can personalize the remains of each loved one. As depicted in the images above and below, 3D printing is quick and can customize each urn with fine detail. It is a fast and quality way to create a customized look for each urn.

There are sites that offer construction instructions for DIY 3D printed urns as well.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The steady increase in selecting cremation means there will be an increase in demand for urns as well. The 3D printing industry can help grieving families honor their loved ones by helping artists/designers to create customized urns that celebrate the lives of the decedents.