Charles R. Goulding and Peter Favata examine 3D printing coming into play to aid in advanced shoulder surgery procedures.

The shoulder joint is made up of three bones that all together form the joint. These bones are the clavicle, scapula, and humerus. Most injuries to these bones and the surrounding ligaments are caused by involvement in sports. Repetitive overhead movements such as pitching in baseball or swimming cause wear and tear over the years.

Shoulder Innovations, founded in 2009, is a medical device development company focused on improving and lowering the overall cost of shoulder replacement implant surgery. With around 53,000 Americans getting shoulder replacement surgery each year, according to the American Academy of Orthopaedic Surgeons (AAOS), people are constantly looking for innovative ways to improve replacement surgeries. On November 2, 2020 Shoulder Innovations closed an oversubscribed $21.6 million in equity financing. This funding is going to support R&D for an entirely new line of shoulder replacement products.

3D Printing

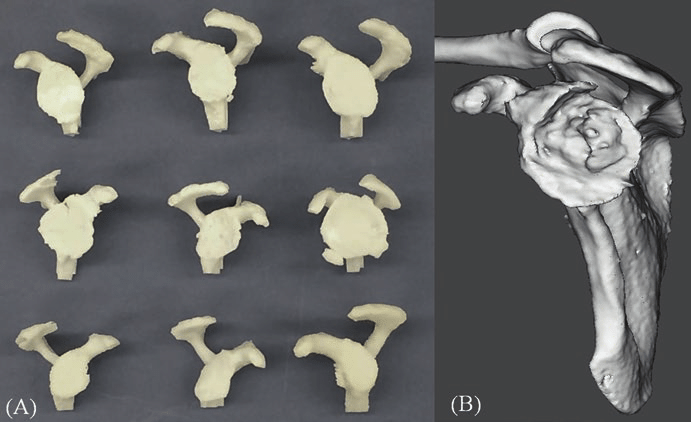

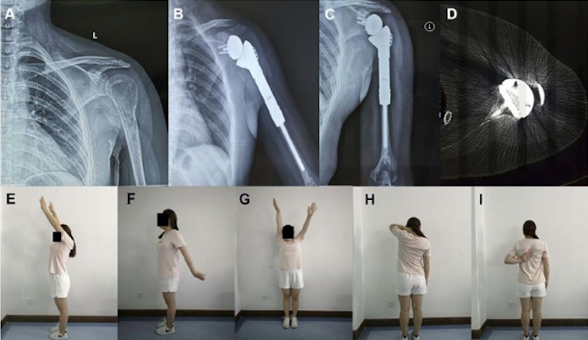

In recent years, 3D printing has been used to assist in shoulder replacement surgeries, as it has in ankle surgeries. 3D printed models of shoulder joints are used to diagnose and prepare for the surgery required.

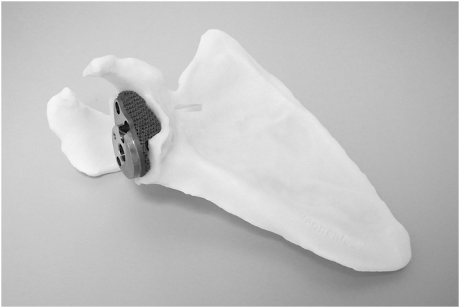

This is achieved by taking a CAT scan of the patient and creating a 3D model using CAD. The 3D model of the patient’s shoulder can be used during the pre-operative process by allowing the surgeon to ensure that the implant will fit properly where needed.

3D printing has also been used to create the implant itself. In cases of extensive bone and joint detritions, whether from physical injury or infection, 3D printing new joints has become an option for some. These titanium implants offer the same movement and flexibility of traditionally manufactured replacement joints.

Orthopedists and designers utilizing 3D printing may be eligible for R&D Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

Shoulder replacement surgery can be needed in people as young as 40 whose pain hinders them from doing everyday tasks. With the use of 3D printing, these procedures are having a higher success rate that is helping more people every day get back to a more active way of life.