Charles Goulding and Adam Friedman consider how 3D printing might impact updates to the latest gaming consoles.

Last week Microsoft released its new Xbox generation, Xbox Series X. Two days later, Sony released its newest console: PlayStation 5 (PS5). The gaming and technology worlds are deeply entrenched with these releases, as they come during a high tide of membership and playing among 18-to-49-year-olds and competitive gamers. And while this will not be the last time that Xbox and PlayStation receive headline news, this current 2020 release presumably marks a period where consoles will no longer be standalone machines and individual property.

Both Sony and Microsoft have ventured into making official online gaming platforms. Microsoft has launched xCloud to stream games from data centers to mobile phones. Sony has not followed suit yet but has explored expanding its gaming capabilities to an estimated 20 million potential gamers who have internet-enabled phones in developing countries. Sony is doubling down on this market and is now utilizing a Razor Blade model and anticipates losing $100 per console hardware item to be offset by overall software sales.

While gaming is moving online and to new markets, PlayStation has still been very successful with selling its physical console to gamers. The console has improved considerably since its first release in 1994, and iterations have migrated the PlayStation console to use, from its beginning, standard RISC circuitry to NVIDIA and to most recently AMD central processing units (CPUs) and graphical processing units (GPUs).

Microsoft has been on its fourth iteration of its console and has expanded original gaming to each console. From a general perspective, Xbox began its fan base on classic quasi-military games such as Halo and Call of Duty and has since expanded its gaming territory and demographic, winning over teenagers and new consumers with games such as Minecraft and most recently, Fortnite.

Both the shift to online gaming and the evolution of consoles have led to a new opportunity for Sony and Microsoft to create and develop less expensive PlayStation and Xbox consoles in the hopes of selling consoles in volume to potential gamers in emerging country markets who can’t afford current retail prices. This is also an opportunity for 3D printing to be used for these video game consoles to produce cost-efficient parts.

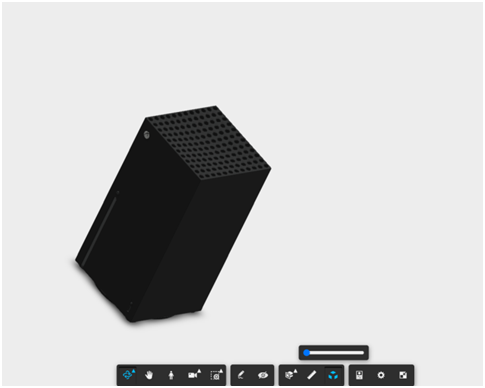

3D modeling Xbox Series X has already begun. In a January 8, 2020 article from Windows Central, a 3D model offered a visualization of how the Xbox Series X console would look. The picture below details the model of a pre-released Xbox Series X and was rendered based solely on attendance at a Microsoft gaming convention in 2019.

As seen in the 3D model, most of the upgrades to Microsoft Xbox have provided the ability to generate less heat and to build smaller consoles than the original square-shaped Xbox One and Xbox 360. 3D printing could be used to engineer shapes and structures that can both maximize heat loss and optimize the volume of the console. The article touts its multiple backports and a 3D modeling viewer accentuates this Dell modem design for Xbox Series X.

This Xbox Series X model can fit inside a living room like a vertical fan tower but has little versatility in fitting in areas with limited space. 3D printing a new Xbox console with specialized resins, detachable parts and with artistic edges for heat fans (e.g., gill fins or lung arteries) could take Xbox to the next level in its design and operation.

Along with the aforementioned considerations for a 3D printed Xbox console, the PlayStation console could utilize 3D printing in a myriad of ways. As of now, the PS5 has a spiraled exterior and is lightweight with custom created faceplates. With 3D printing, there could be many revisions and iterations on the spiral shapes with shells, galaxies and mathematically inspired shapes rendered on 3D printing software and/or CAD modeling. The current controller for PS5, the Dualsense, could be fabricated from many available 3D printing materials and be customized for different consumers, with consumers even being able to design their own 3D printed templates. This is similar to what Sony is already doing with Faceplates.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

These introductions mark a monumental foray within the video gaming industry; it presumably marks an end to traditional consoles for video game companies. However, new technology, namely 3D printing, could lead to a revival of consoles and continued success on the market.