New research could result in a 3D print material that is truly recyclable.

Plastics recycling is gaining attention as the world gradually begins to recognize the enormous microplastic problem that now spans the globe. Recycling could significantly reduce plastics waste, but it has not really happened in spite of considerable efforts.

One of the issues turns out to be chemistry. Many common plastics are made from polyolefins, but there’s a problem. This molecule cannot easily be chemically broken down and remade new: there is a marked loss of quality each time this is attempted.

The result is inefficient recycling and in many cases, placing the object in a landfill or dumping it in the ocean. Both of those are bad news for the environment due to microplastic contamination.

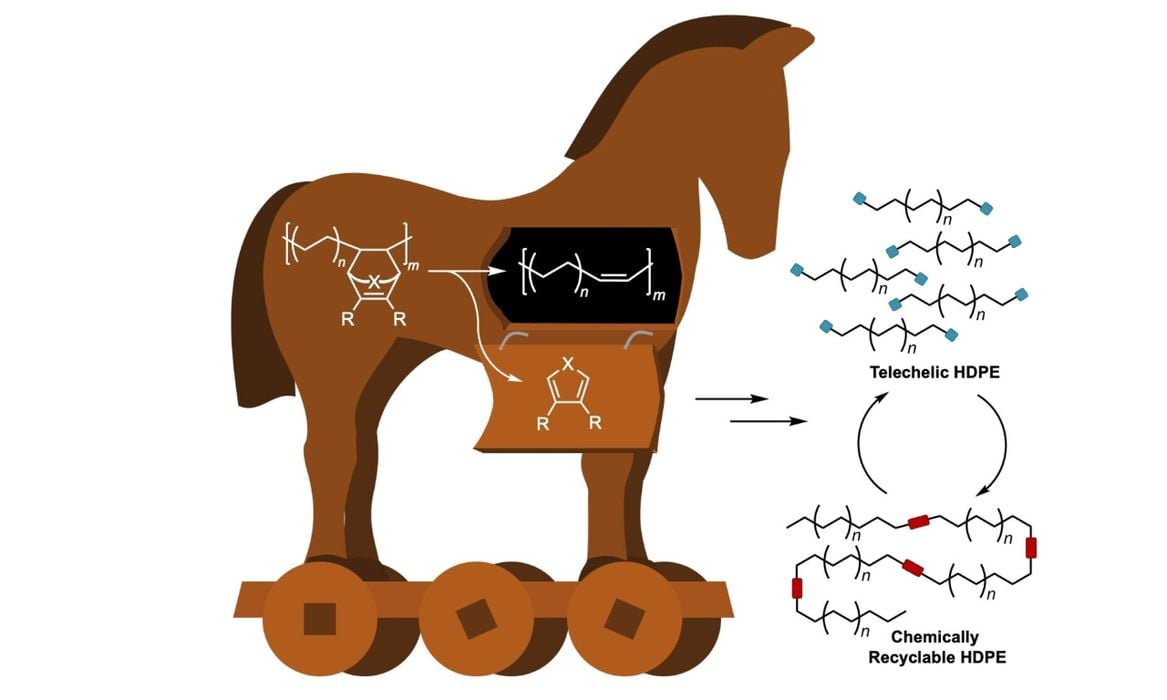

The new research from Cornell proposes a redesigned polyolefin molecule that contains a special co-monomer. This item, when heated, releases the bonds and causes the molecule to break down into much more easily to handle split molecules. These can be reconstituted into fresh plastic, just as if it were new material.

Phys.org explains:

“By this method, the team was able to produce polymers with thermal and mechanical properties corresponding to those of high-density polyethylene (HDPE), a very important and widely used plastic. In contrast to HDPE, the new material has ester linkages along the polymer backbone. When recycled, the polymer chains can be chemically split at the ester bonds to regenerate the original macromonomers. After purification, these can be repolymerized again, without a loss in quality.”

HDPE just happens to be a 3D printable material, although it isn’t particularly popular. My thought is that in the future it might be possible to create 3D printer filament using this “true recyclable” HDPE mix and potentially kickstart a proper 3D print recycling program.

Such a program would have to be very accessible, unlike most of the current programs that have many constraints and extra costs. It may be that the nature of the efficient recycling process could lower costs and potentially even offer savings for 3D printer operators.

Even if there are little to no savings, industry will eventually have to make far more extensive use of recyclable materials in the future, so this research could be of great importance: modified versions of this approach may work on other plastics.

Via Phys.org