HP expands their unusual packaging solution with a new client.

HP’s strategy for acquiring new business for their increasingly popular MJF 3D printing system is a little different. Rather than just selling the machines on the merit of specifications, they have been digging deep into application territory.

The idea is to identify and cultivate entirely new applications well-suited for their systems, which effectively create entirely new markets they can sell into. This is a very effective approach, yet it is also very challenging to execute.

It’s believed that HP has been spending considerable effort behind the scenes working on this approach, and from time to time we see evidence that it’s working. This is one of those times.

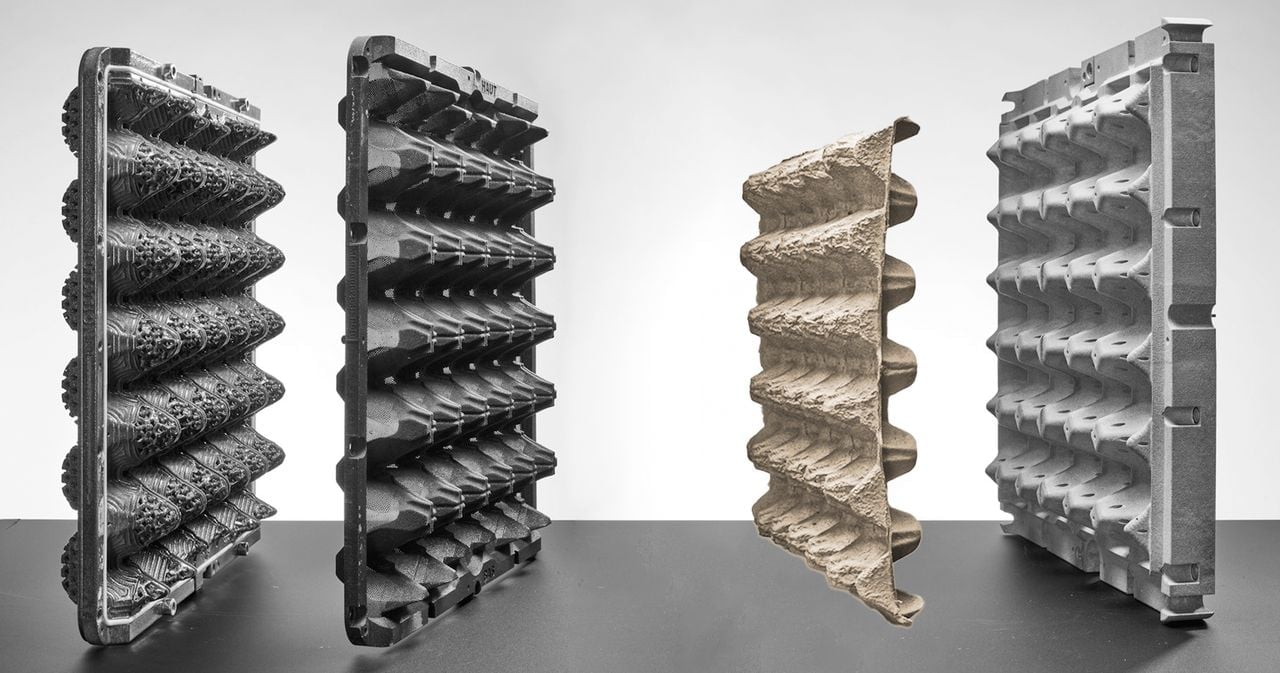

In the past HP unexpectedly announced radical new applications for MJF. One was the production of paper-based molded products, and HP developed what they call the “Molded Fiber Tooling Solution”.

The idea here was that those cardboard molds you often see holding product components stable during shipping could be made more efficiently with 3D printing. Instead of spending much cash on a metal mold, just 3D print one instead. This would be quicker and a lot less expensive. It would also allow the packager to more frequently redesign the packaging as change occur.

A modification of this approach was used in an unusual bottling solution. HP worked with a bottler that made products from paper, which turns out to be a kind of modification to the molding solution.

Now we hear that yet another manufacturer has adopted the molding solution, Omni-Pac Group. This European company produces packaging with an emphasis on sustainability, which aligns with HP’s molding solution.

Omni-Pac Group CEO Pablo Libreros said:

“Our collaboration with HP allows us to revolutionize the production of molded fiber at an industrial scale, transforming the development, launch, and production of molded fiber applications. This not only reduces environmental impact but also pioneers sustainable packaging solutions. Enabling us to achieve over 500 tons per machine per year through digitalization, the level of CO2 savings will continue to improve as our collaboration with HP progresses.”

That is a significant use of the equipment.

While this is but one more sale of the product, I feel that HP could be on to something big here. There are a vast number of packagers in the world, and each of them could potentially be a customer for the Molded Fiber Tooling Solution. HP also does not seem to have any competition from the 3D print industry, so it could be an open field for them.

The thin edge of the wedge is always small, and that’s what we might be seeing here.

Via HP