Charles R. Goulding and Preeti Sulibhavi examine the opportunities opening for additive manufacturing as a result of the conflict in Ukraine.

As the war in Ukraine rages on, there are several developments to consider, one of them being the fact that General Dynamics (GD) has won a Ukraine arms deal. General Dynamics, the US aerospace and defense giant, has booked its first order related to Ukraine. The contract is for munitions totaling US$370M in the third quarter. We have covered how High Mobility Rocket Systems (HIMARS) is being supplied by the US to Ukraine and we have covered GD’s submarine contracts as well.

The deal has gotten a lot of attention because it is reported that it has increased in General Dynamic’s land weapons systems, including its Stryker, Abrams and MPF battle tanks. In August 2022, Poland placed a US$1.1B Abrams order. This should get the 3D printing industry very excited.

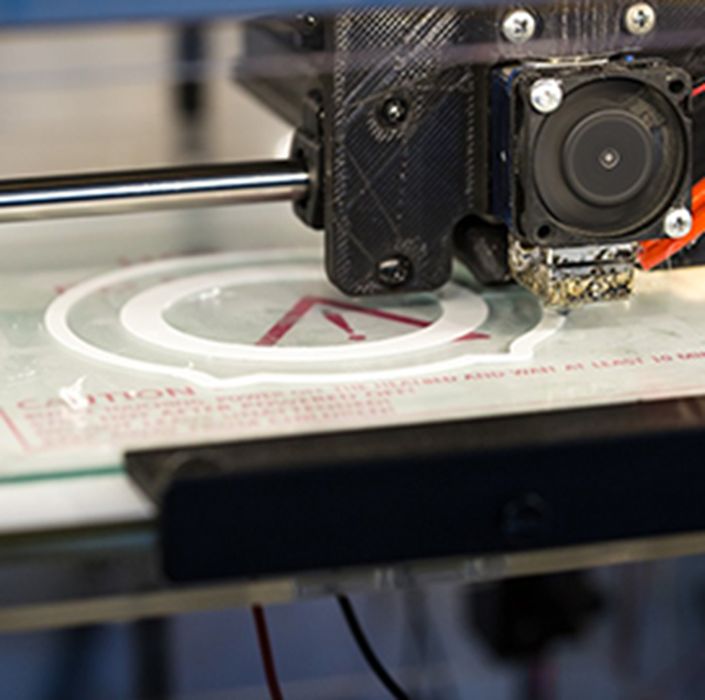

In 2019, GD collaborated with GE Additive to integrate 3D printing into the production of metal components for combat vehicle platforms. Both companies have also worked to identify the potential additive manufacturing approaches to reduce lead times and increase the performance of components.

In addition, GE Additive’s production facility in Pittsburgh has 3D printed a titanium cable guard that is being transitioned to production by GD Land systems. This one-piece titanium component was designed by General Dynamics to replace an 18-piece welded steel component, yielding an 85 percent weight savings compared with the existing part. The cable guard will be the first AM metal production part on a US ground combat vehicle.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

GD has a long history of providing defense industry products and its manufacturing expertise, including 3D printing should be of great assistance in the Ukrainian war effort.