3D Systems announced a broad new program to 3D print human tissue.

The new “Regenerative Tissue Program” intends on producing “vascularized, patient-specific living human tissues”. However, they will not be producing functioning organs.

Nevertheless, this is a monumental step forward in bioprinting. Up to now there has been a huge barrier to cross, namely vascularization.

The problem is that while it’s fairly straightforward to deposit living cells using a 3D printer (also known as a “bioprinter”), those cells require nourishment. After all, they are literally alive, at least when they were printed.

Nourishment typically is provided by keeping the completed print in a bath of nutrients that can soak in to provide sustenance to the cells. However, if you happen to print a thick chunk of tissue the nutrients cannot reach the cells and they quickly perish.

For many years this problem has limited the use of bioprinting to applications that require only thin prints, such as skin.

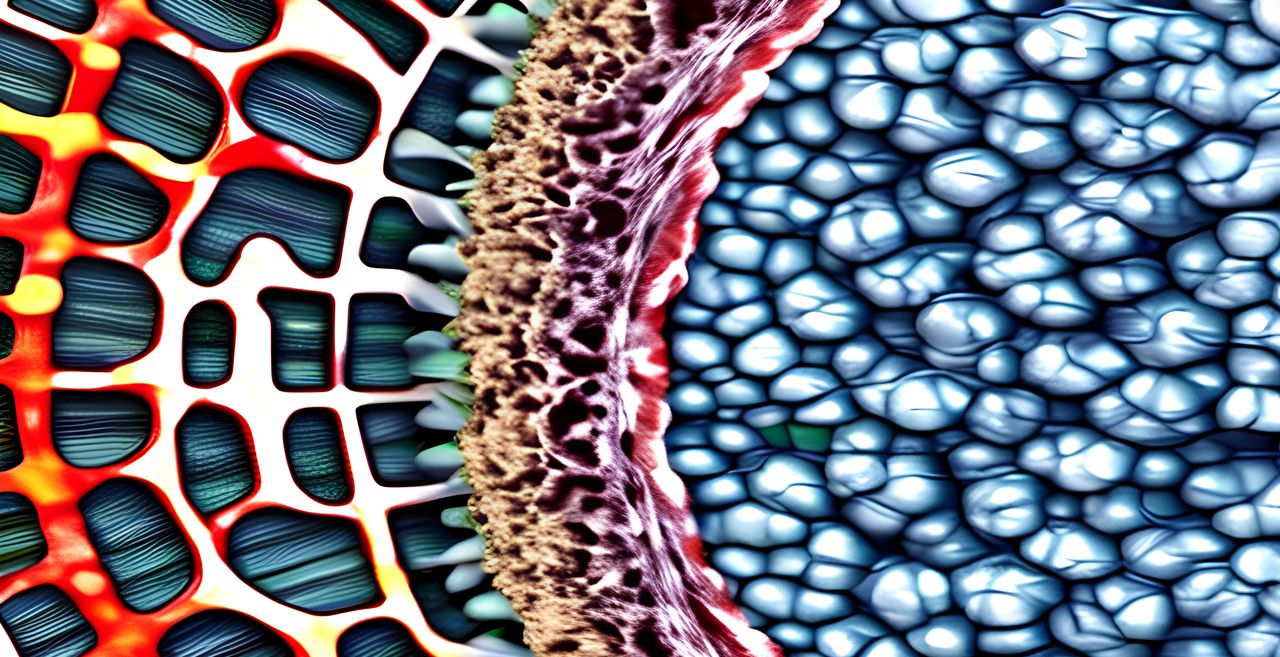

What has been desired to breakthrough this barrier is vascularization. That’s the simultaneous 3D printing of vascular channels that can carry nutrients deep into the print, just as occurs in living tissue.

While there has been plenty of research in this area, it now seems that 3D Systems has been able to commercialize an implementation of the concept. That should open many doors for their future in medical 3D printing.

While the new regenerative platform specifically indicates it is “non-organ”, it sounds very much that is a future goal for 3D Systems. CEO Jeffrey Graves explains:

“The level of innovation we’ve been able to unlock with our solutions for regenerative medicine is allowing us to deliver an unmatched level of complexity and precision. We’re proud of the progress we’re making in the development of bioprinting solutions for human organs including lung, liver, and kidney. With this as the foundation, combined with the expertise gained through years of experience in the manufacturing of personalized medical implants, we have quickly moved into the development of patient-specific human tissues that can dramatically alter how patient care is delivered.”

But how does this work? 3D Systems explains:

“Through the power of advanced 3D modeling, novel bioinks, and high-speed high-resolution 3D bioprinters, 3D Systems is developing an acellular biointegrative scaffold to regenerate adipose tissue. This scaffold can be combined with intraoperative cellularization (i.e., fat grafting) with adipose cells harvested from the patient during surgery. This results in a regenerative scaffold that mimics the patient’s anatomy and physiology to help deliver improved surgical outcomes— addressing the clinical need for a long-term reconstructive solution for soft tissue applications.”

And:

“Over the past 12 months, 3D Systems has conducted in-depth research that is guiding its efforts into building a platform for tissue regeneration. This includes completing multiple large animal studies demonstrating a proof-of-concept for biointegrative scaffolds for adipose tissue regeneration. In particular, the company is investigating host-mediated engraftment of a passively-implanted angiogenic scaffold to explore the ability to grow new blood vessels. Additionally, they have demonstrated the ability for direct vascular connection of an anastomosed (i.e., connecting directly to the vasculature) scaffold. The scaffolds are constructed at the human scale from a family of biocompatible materials with tunable material properties which the company believes will be able to address and personalize human breast-size tissue reconstructions.”

This platform is likely the result of combining of 3D Systems many years in this application area, their several acquisitions of bioprinting technology and materials, and their software developed for healthcare.

The company believes they will be able to address “multiple soft tissue applications” using the regenerative platform.

3D Systems’ first target application will be for patient specific breast tissue reconstruction, a process they’ve trademarked as “RBT”, Regenerative Breast Tissue.

Via 3D Systems