3DEVO announced an unusual accessory for their thermoplastic recycling system, the GP20 Hybrid Shredder/Granulator.

Let’s back up a bit here. 3DEVO is a Netherlands-based company that is pretty much the only surviving operation that produces desktop equipment capable of producing usable 3D printer filament. Many ventures have tried to do this, but 3DEVO has a system that actually works.

Their system involves pouring thermoplastic pellets into the filament maker’s hopper, where they are heated and extruded into filament. A take-up system spools the fresh filament, ready for use in a 3D printer.

It sounds like an easy process, but it’s not. It requires highly precise real-time monitoring and control of speeds, temperatures and extrusion diameter. All of this is handled by the 3DEVO equipment, which includes profiles for various types of materials.

These days few individuals make their own filament, so 3DEVO’s clients are typically labs or universities wishing to experiment on unusual mixes or colors of filament.

If you can make your own filament, then one immediate idea would be to recycle old thermoplastic into new filament. Most 3D printer operators have mountains of old prints, leftover support material and end-of-spool segments to deal with, so you’d think this would be a great idea.

There are many challenges, however, as the material type must match, colors may mix into something ugly, and you need a consistent source of raw material. One of the biggest challenges, however, is to convert the scrap material into usable pellets.

Fresh thermoplastic from chemical providers is typically supplied in uniform pellet form, where it can be stored, poured and processed easily. Filament production machines assume that is the form of material input. However, scrap materials for recycling are most definitely not in pellet form and they must be transformed.

Previously, 3DEVO announced a “shredder”, which could take reasonably-sized chunks of material and chop them into pellets of appropriate size for filament production. I’ve seen the SHR3D IT Shredder in action, and it works quite well.

The SHR3D IT Shredder is perfectly suitable for experimental use, as it has a relatively limited capacity.

3DEVO GP20

Now 3DEVO announced a much more capable shredding device, the GP20.

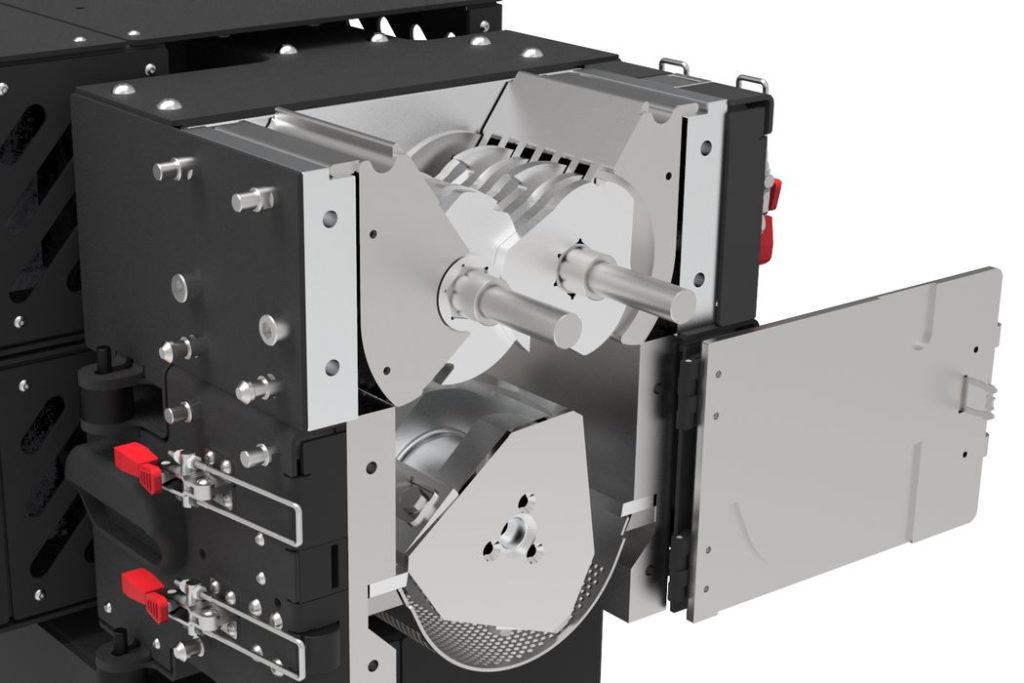

It’s actually a hybrid device that’s capable of both shredding and granualization. It’s also “smart”.

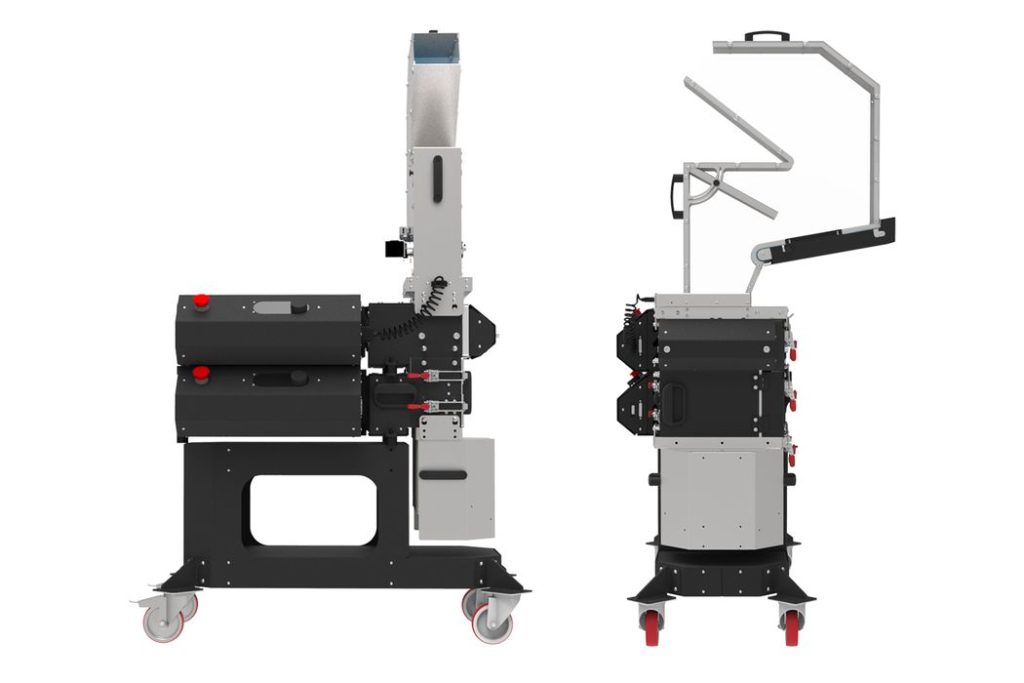

From the images you can easily see that the GP20 is a far more complex device, weighing in at a huge 125kg. This machine includes two powerful motors, which makes the grinding process far more efficient.

The GP20 also includes an incredible 14 blades, which appear to be interchangeable to match the specific materials being processed.

3DEVO says you can “throw” many plastic items into the GP20 and they will be successfully processed:

- Purgings

- Plastic Bags

- Film

- Plastic Bottles

- Glass Fiber Reinforced Plastics

- Carbon Fiber Reinforced Plastics

- 3D-Prints

- Injection Moulded Parts/Waste

That’s quite a varied list of items, demonstrating the flexibility of the GP20.

But the GP20 is also “smart”. 3DEVO said:

“Focused on giving the highest output, the automated system controls the feeding of any thermoplastic thrown into it. As multiple sensors react to how your materials perform, the system ensures that the shredder responds to the material, preventing it from degrading within the cutting chamber and ensuring your safety.”

The GP20 can produce particles of a required size by using pre-made profiles for common materials. These can be tweaked as necessary for experimental production.

Why such a powerful machine? 3DEVO explained that it’s targeted at operations that hope to move from experimental filament making to production filament making. The GP20 can be used for both purposes, as it is fast enough for reasonable production. It can also be cleaned very quickly if one is switching materials.

The GP20 is not for everyone, but those that are in the business of making small runs of experimental or unusual filaments from recycled material may find the GP20 of great interest.

Via 3DEVO