3D Platform has published a set of simple benchmarks that anyone could easily use.

3D Platform is best known for their rather large 3D printers. Years ago they took the standard FFF 3D printing process and scaled it up to enormous sizes. Along the way, they had to contend with newly found issues associated with large-format 3D printing, but they found a way to solve them using ingenious extruders, super-fat filament, pellet materials and much more.

Now I’ve learned they’ve published a set of 3D models that can be used for tuning their 3D printers. Of course, these are simply .STL models that can be used by anyone with a 3D printer.

3D Print Benchmarks

There are plenty of 3D models that can be used for benchmarks. The idea is to have a standard shape that can be repeatedly 3D printed to gradually hone in on the optimum print parameters for a given material.

These days when you say “benchmark”, one of two things comes to mind.

First, there’s the classic #3DBenchy, a fun boat 3D model that just happens to include a number of geometric features that can give a printer a good test. Many 3D printer operators simply print and tweak “benchies” until they look good.

Secondly, there are a dizzying array of far more complex 3D models that can be used for contorting your 3D printer in tests. There are tests for overhangs, temperature, leveling, surface quality, curves, and pretty much everything else. Some highly complex benchmarks attempt to include as many of these features as possible in one wild geometry.

I find the super-complex benchmarks difficult to work with. Even worse, they’re always changing; today an inspection of Thingiverse revealed around 400 items tagged with “Benchmark”. What is the best one to use? Who knows?

Honestly, the first object I 3D print on a new device or material is a simple 10mm cube. That basic object can tell you a great deal about the state of affairs of the 3D printer and the current material, believe me. Once I perfect the cube, then I might move on to other more complex benchmarks if warranted. Sometimes I just dive in on the target 3D print at that point because the cube’s fitness could be sufficient to indicate likely success on the final 3D print. No need for fancier benchmarks in that case.

3D Platform Benchmarks

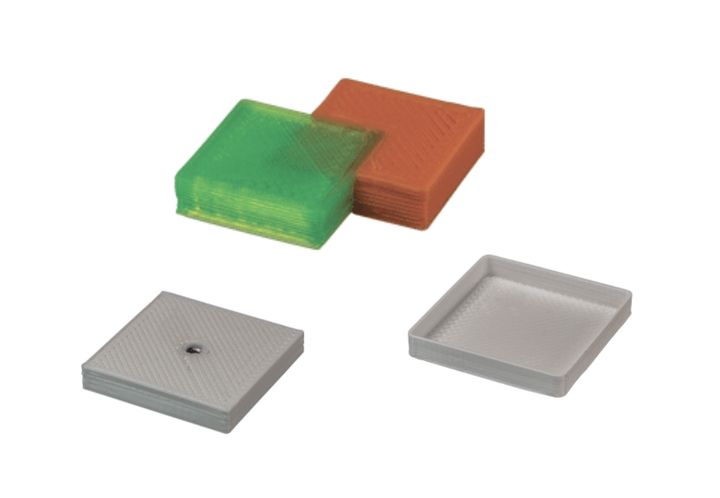

The 3D Platform benchmark suite is quite different from the usual hyper-complex benchmark 3D models, as it contains only very simple and easy to 3D print models. The 3D models include:

- Chip — Basic test

- Thin-Wall Box — Tests thin walls, of course

- Two-Color Thin-Wall Box

- Single-Color Infill

- Top Layers Test — Tests surface finish

- Two-Color Alignment Test — Interlocking objects

- Two-Color Infill

- Metal Insert — Testing insertion of a metal nut

- Breakaway Support — Tests overhangs and processing

As you can see, these are far from the very complex 3D benchmarks often seen on public repositories. Instead, these are incredibly simple 3D models that will all be easy to 3D print.

If you can get these printing correctly, you’re 95% of the way to 3D print perfection.

3D Platform includes written instructions for using each of the benchmarks, but be aware that the instructions are tuned for 3D Platform equipment. However, if you read them and don’t happen to have a 3D Platform device you can get a good notion of what to do. They’re not that complex. I particularly like their “What to look for” segments in the instruction, from which you can learn a great deal about print quality.

I am going to change my standard cube benchmark to some of 3D Platform’s benchmarks, as they will be very easy to use and get you the results you need for quality 3D printing.

Via 3D Platform