There may soon be a way to 3D print bones directly into patients.

This is the proposition of researchers from UNSW Sydney, where they have been working on a new form of bioprinting that could enable in-body 3D printing.

Bioprinting is certainly not new; it’s been around for over a decade in various forms. The general approach is to 3D print a “scaffold”, a sparse structural arrangement, and then infuse it with the desired living cells. The cells grow according to the geometry of the scaffold, and then the scaffold eventually dissolves, leaving only the living cells.

The bioprinting of bones has been particularly challenging, as it also involves involve crystallizing solid structures. The researchers say:

“Despite recent advances in the biofabrication of complex engineered tissues, replication of the heterogeneity of bone microenvironments has been a major challenge in constructing biomimetic bone scaffolds.”

Typically the process has involved performing the bioprinting in a lab, and then implanting the resulting tissue into the patient. This is because the bioprinting process generally involves nasty chemicals, temperatures and other factors that are incompatible with the human body. Print first, insert later.

Now there may be a way to short-circuit this process with a new technique. Evidently researchers at UNSW Sydney have developed a way to 3D print without the nasty stages. They explain:

“Using this technique, complex bone‐mimicked constructs are made at room temperature without requiring invasive chemicals, radiation, or postprocessing steps. This study demonstrates that mineralized constructs can be deposited within a high density of stem cells, directing the cellular organization, and promoting osteogenesis in vitro.”

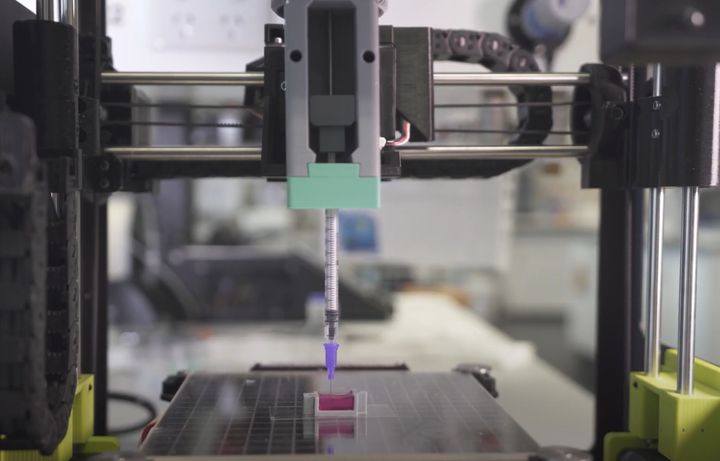

Their process involves 3D printing the specialized material with a syringe-equipped 3D printer into a microgel matrix. The gel supports the material as it is extruded, ensuring the desired shape is achieved.

While the researchers performed the experiment in the lab, the conditions of extrusion are such that it could eventually be possible to bioprint bones directly into the human body.

Imagine a case where a patient has had a tumor removed, leaving a void where previously bone existed. This area could be 3D scanned to prepare a customized 3D model of the replacement bone section. Then, the patient could undergo a procedure where microgel is placed in the void and bioprinting the new bones occurs.

One question I have is about timing. When living cells are bioprinted into scaffold form, it usually takes days or weeks for the living cells to multiply and assume their target shape. This growth period is likely the same duration, except that it occurs in a living, moving human. I would expect there might have to be some way of constraining the affected area to ensure the bone grows to the correct geometry.

But that’s a step for the future, as this is an area that hasn’t really been explored yet.

Via Wiley