Ackuretta announced a new dental 3D printer they say is capable of chairside use.

3D printing is increasingly used in the dental industry, as all kinds of personalized appliances must be produced for individuals undergoing dental procedures. Typically these are based on 3D scans obtained from the patient.

The typical workflow for dental 3D printing is for the dentist to obtain the scan, which is then sent to a dental laboratory for processing. The lab will clean up the 3D model and produce the requested dental appliance using their 3D printing equipment.

Eventually, the finalized 3D print is shipped to the dentist. This workflow causes two visits to the dentist for patients: one to diagnose and capture the scan data, and a second later to use the 3D printed appliance.

The concept of “chairside” dental 3D printing is new, and I’ve only heard of two companies pursuing this avenue.

The idea of “chairside” dental 3D printing is to dramatically increase the speed of printing and at the same time vastly simplify the operational aspects. This can potentially enable the production of required dental appliances at the dentist’s location and completely avoid sending and receiving from a distant dental laboratory.

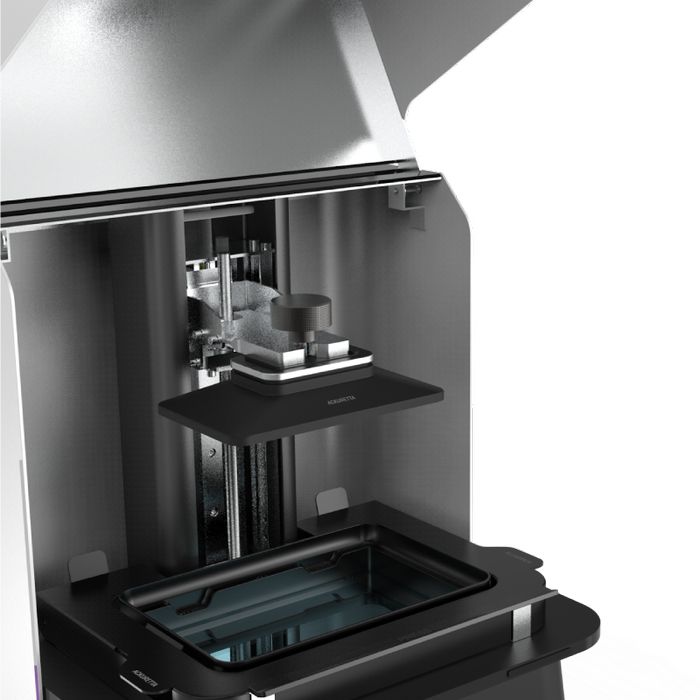

Ackuratta’s new SOL 3D printer is proposed as a chairside solution. Let’s take a look at its specifications to see whether it meets chairside levels.

Like most dental 3D printers, the print volume is small at 128 x 80 x 140 mm, and that’s okay because dental appliances must fit into patients’ mouths, which are not large.

The pixel size, which is the smallest possible detail that can be reproduced by the MSLA SOL system, is 49 microns, or 0.049mm. This is more than sufficient to produce objects of the required accuracy.

Ackuretta has enhanced the light engine on the SOL. It includes 54 separate LEDs that have been calibrated for optimal illumination. This means that prints should have somewhat better quality than stock LED illumination systems.

The key spec on the SOL system is its print speed, which is an incredible 45mm per hour. Because this is an MSLA system it doesn’t matter how much is printed on each layer because every layer takes the same amount of time to print. Thus the elapsed time to produce a given object is simply a ratio of its height.

It’s important to remember that dental appliances tend to be flat in orientation, and so their height is usually quite low, only a few centimeters at most. This means that the SOL system can likely produce usable dental appliances in less than an hour.

For ease of use it’s a bit more complicated on the SOL system. Many dental 3D printers use proprietary materials to ensure print quality and predictability (and extra revenue), but the SOL 3D printer is open materials. It can accept any suitable resin.

This makes it more challenging for the user because so many different parameters might be used on a random resin. However, Ackuretta seems to have solved that problem by providing “more than 100 revalidated materials”.

In other words, they are providing a very extensive library of print profiles for well-known third party resins. This will certainly simplify the workflow for dental 3D printer operators.

Based on what I can see in the material provided, it seems that Ackuretta indeed has produced a chairside dental 3D printer.

The price of the SOL system is US$4299, but apparently they’re offering a massive discount for early-bird buyers at 42% off. That’s US$2,493 by my calculations. Those who sign up now will receive notification when the device is officially available and receive the discount.

They’ll also get a two-year warranty on the product, which is also notable in the 3D printer world.

Via Ackuretta