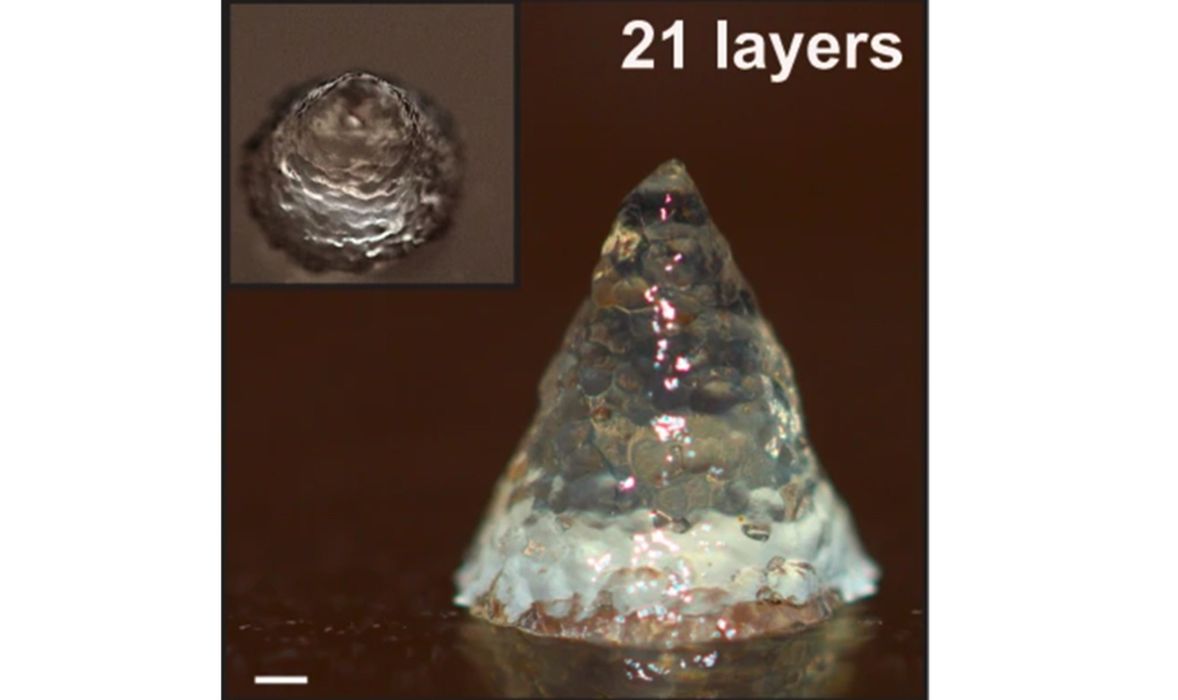

Solid 3D-printed cone made of microbial ink [Source: Nature Portfolio]

Charles R. Goulding and Randall Rothbort examine a new approach for producing bioinks using microbes.

While 3D printing is often most associated with plastics, polymers, and metals that are used to additively manufacture components, many scientists and researchers have been looking into unique and innovative avenues for 3D printing. One notable area of research is in programmable microbial ink, which uses living organisms to allow for 3D printed structures to perform functions previously unavailable. One research team from Boston, led by Dr. Anna M. Duraj-Thatte and Dr. Avinash Manjula-Basavanna, is at the forefront of this biotechnological push, as they have revealed the first programmable printable gel made entirely of biological proteins produced by microbes.

What is a Bioink?

While traditional 3D printing utilizes basic materials, bioink is a material that can be used to 3D print live tissue or organic material. Often, these inks are composed of bioengineered organisms or cells, along with additional materials, that can be used to form the material. This “ink” can be extruded much like other 3D printing materials into filaments that retain shape. However, extensive work must be done for each bioink to ensure it maintains the necessary physical properties required for 3D printing. This is caused by the sensitivity bioinks often exhibit with normal 3D printing processing conditions, making them more difficult to use.

Bioinks have a multitude of use cases, most notably in the biomedical field, where many see an opportunity for developing lab-grown organs, implants, medical devices, treatments, and surgical models. Many companies and research teams have begun developing their own solutions, including 3D Systems, as discussed in our prior article “3D Systems’ Pivot Towards 3D Bioprinting”.

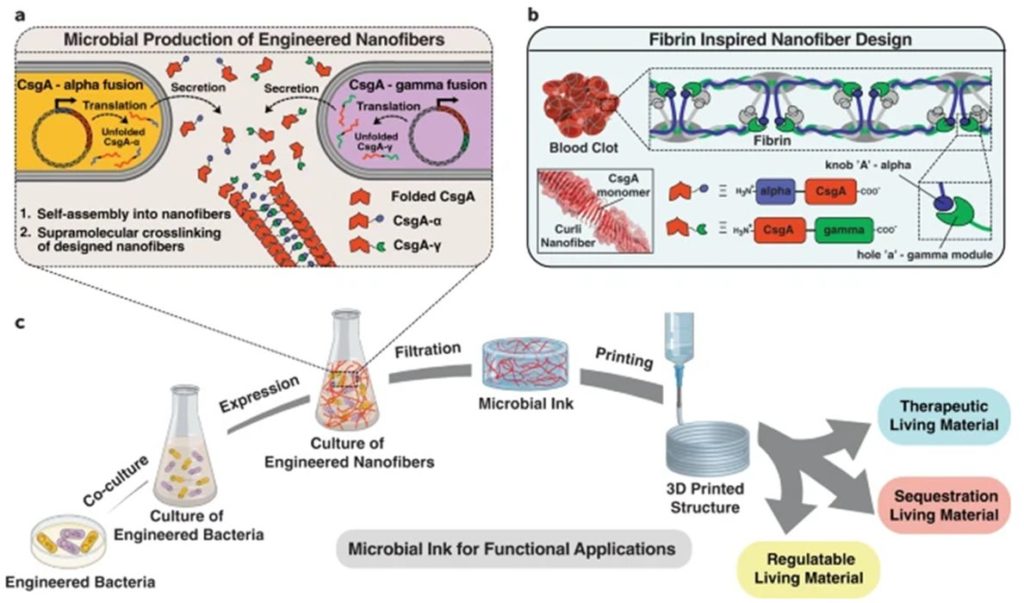

The Boston team began this project with the goal to release anti-cancer drugs automatically, as well as to capture toxins from the bioink’s environment. Others see uses in other engineering disciplines, such as for biosensors and even for bioengineering structures in areas with little natural resources (including, as Manjula-Basavanna suggests, a potential moon settlement).

Using E. coli to 3D Print

The MIT research team who developed this new microbial ink had to overcome a variety of unique challenges during the development process.

This advanced bioink had to have a “tunable mechanical strength, high cell viability, and high print fidelity”. It was also vital that the ink had an appropriate viscosity to allow for the extrusion of the ink, but also high enough to allow the ink to retain its shape once printed. To accomplish this, scaffolding is often used in a bioink’s structure to allow for it to retain shape (as discussed in our prior article “Greater Customization Of 3D Printed Scaffolds Now Possible With New Bioink”).

However, this process requires a medium programmed to construct the appropriate scaffolding and structure. For this, the Boston team utilized genetically modified E. coli cells within the gel to produce bioink structures that were customizable and able to produce the desired effect. These scaffolds take the shape of curli nanofibers, which are small, curled subunits that crosslink together to form a structure.

These nanofibers can only be created by certain strains of bacteria, one of which being E. coli, making it an optimal bacterium to be used for this programmable bioink 3D printing process. However, these organisms usually cannot create any complexity in their structures, leading the Boston research team to genetically program the microbes to construct the lattice scaffolds necessary for 3D printing.

During their research process, the team was able to create structures up to 21 layers thick in various shapes. The team also reprogrammed these E. coli cells to create various scaffolding matrices and functions as needed past the original desired effects for the research project.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

As companies and research groups continue to experiment with new major applications for 3D printing technology, programmable bioinks serve to open the door to new advancements for many different applications. As Dr. Duraj-Thatte and Dr. Manjula-Basavanna’s team has shown, bioinks have the potential to allow for customized 3D-printed solutions in new fields that other forms of 3D printing could not address. As they, along with others, continue to innovate in this field of study, there will surely be more advancements that allow the technology to be more scalable, efficient, and advanced.