Anker launched their first 3D printer, the M5, on Kickstarter.

Anger is most well known for their electronics accessories is now producing desktop 3D printers, under a new brand, “AnkerMake”. Their first product is the M5, which was launched on Kickstarter.

The M5’s key feature is extreme print speed, and we’ll take a good look at that below.

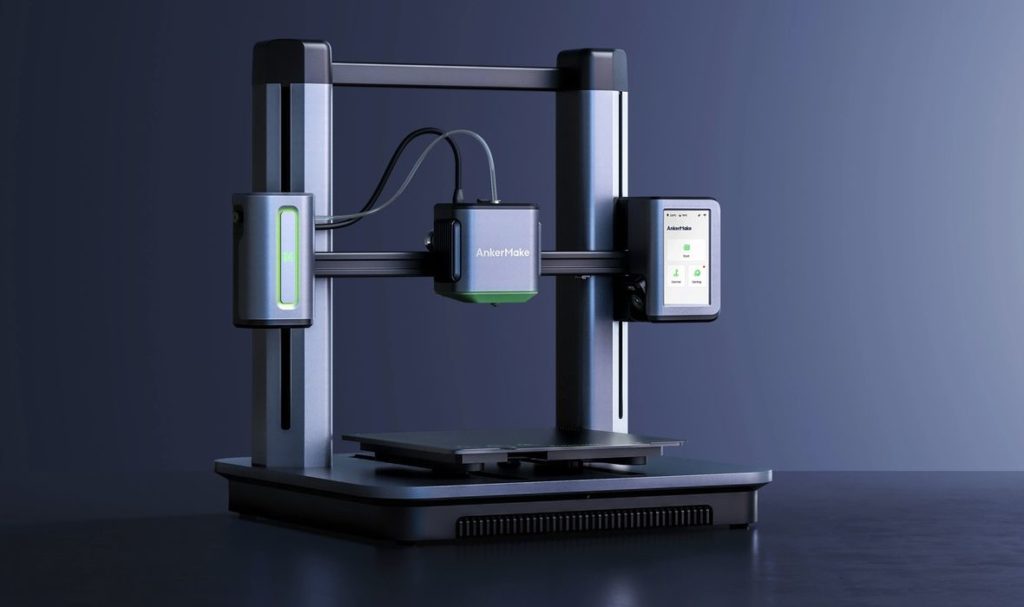

The M5 appears to be an interesting device, although I have some questions about the strategy here that I will get into later. First, let’s look at the device itself.

AnkerMake M5 Specifications

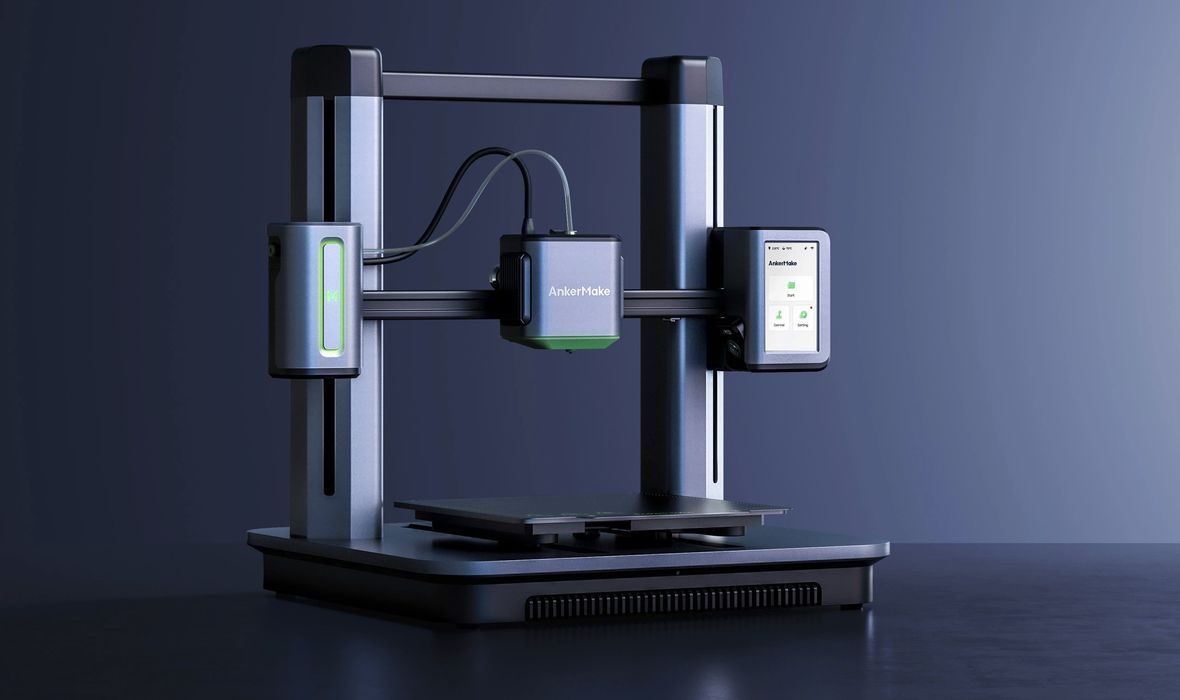

The M5 is a FFF device with a single 0.4mm nozzle and a 1.75mm direct drive extruder. AnkerMake calls it the “Ultra Direct Extruder” for reasons we’ll see in a moment. The hot end can reach 260C, enabling the M5 to successfully 3D print common materials including PLA, ABS, PETG and flexible TPU.

The M5 includes a 4.3” touchscreen for control, a filament run-out sensor and handling workflow, and a generous build volume of 235 x 235 x 250 mm.

The print surface can be heated up to 100C, and it’s a magnetically attached spring steel plate roughly coated with PEI for adhesion. There is no smooth surface on the M5 at this time.

An automatic leveling system is included, and it uses a 7 x 7 point array for calibration. Silent stepper motors limit the M5’s operating noise level to only 50dB, and that’s pretty quiet.

There are two processors in the M5, a Dual XBurst and an XBurst, both of which are 32-bit processors.

WiFi and USB-C connections are available on the M5 for connectivity and to supply local GCODE files. AnkerMake said the M5 is able to handle over the air updates to its firmware.

Software for the M5 seems to be agnostic, as they say you can use any of Ultimaker Cura, Simplify3D, PrusaSlicer, as well as their own internally developed “AnkerMake Slicer”, which will no doubt enable use of some more advanced features not handled in other slicing systems.

AnkerMake M5 Features

So far the M5 seems to be a pretty standard device, but it includes several unusual features not often found on desktop 3D printers.

The M5 does not have an enclosure, as it is an open gantry style device. However, most of the components are encased in plastic or metal. For example, the Z-axis lead screws are fully enclosed within aluminum cases. This should eliminate dust accumulation and possibly lengthen maintenance cycles.

The toolhead is similarly enclosed with various plastic covers. This makes the M5 look much more professional, but at the same time could make maintenance more challenging. I’m concerned about typical print failures where the hot end is covered in molten plastic, and that might be big trouble on the M5.

There is an onboard camera mounted at the end of the X-axis near the control board. This means it travels up and down as the Z-axis moves. Interestingly, the 1080p camera includes a night vision feature, enabling a view of the print in darkness. I don’t think I’ve seen that on any other 3D printer camera system previously.

AnkerMake Remote Control

With a WiFi connection, dual processors and a camera system, you might think AnkerMake has remote control capability, and you’d be correct.

The M5 is connected to the AnkerMake Cloud via an iOS or Android app. The app allows you to not only view live prints, but also control them. You can stop a job, or start one if the bed is clear — which you can check with the camera system.

The cloud system enables access to the device from anywhere, as it goes through the Internet. This is different from most Octoprint installations where you have access only if you are on the same network. Not so with the M5.

The control system also enables the capture of timelapse videos that can be shared on the cloud. These work, but are restricted to the view from the camera position that moves upward on the Z-axis.

A very interesting electronic feature is the apparent ability to automatically detect print failures. Presumably the prints can be stopped if one is detected, or at least warn the operator via the app. This seems to be a feature similar to the Spaghetti Detective or QuinlyVision. It will be interesting to see how this feature works after many users begin operation.

AnkerMake M5 Print Speed

The big feature of the M5 is print speed. AnkerMake explains that while normal 3D printers have prints speeds of only 50mm/s, the M5 can reach 250mm/s. That would appear to be 5X faster, but it’s not really that fast.

How has AnkerMake made the M5 able to reach higher print speeds? They’ve made slight modifications to several components.

First, they have tweaked the heating system in the hot end. The 60W heater is able to heat material faster, which is what you need to do when a filament is flying by at high speed.

They’ve made the frame of the M5 more rigid with the aluminum casings that enclose the Z-axis lead screws. This should reduce vibration that will occur at higher print speeds.

Finally, they’ve beefed up the Y-axis stepper motor, which moves the print plate back and forth. Of the three stepper motors involved in the motion system, the Y-axis would take the bigger beating during operation, so this makes much sense.

AnkerMake cites an example print time advantage, saying they 3D printed a #3DBenchy in only 2:10, whereas a “normal” 3D printer would take 9:19. This doesn’t seem correct to me, as even slower printers could print the object in about 4-5 hours.

But there is no doubt that the M5 can print quite fast, but your actual results are going to depend on what you are printing.

AnkerMake M5 Questions

Kickstarter launches are always a bit suspicious, but this one is less so because Anker is a well-established company with extensive knowledge of how to manufacture products at scale. No concerns there.

I am a bit concerned about the exaggerated manner in which the product is portrayed, however. Boasting of 5X print speed is simply not true, unless you are printing a single extrusion line with no turns. I suspect most people will see print speeds in the 120mm/s range in real life activity.

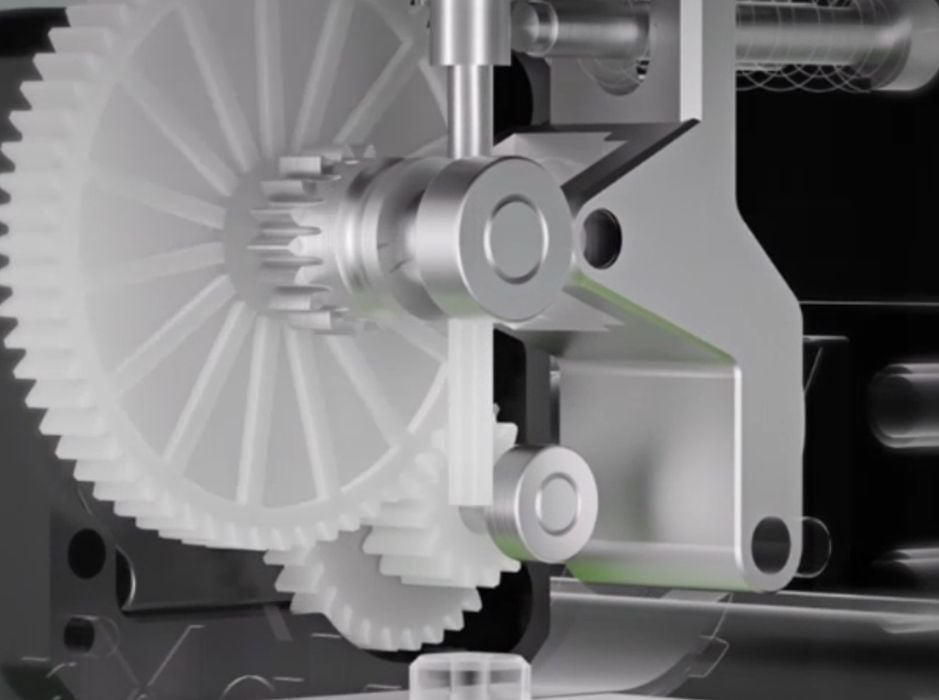

AnkerMake doesn’t say, but I’m wondering if the Ultra Direct Extruder has dual toothed gears. It does not appear so in their animation, and this could be an issue for high speed printing. [UPDATE: Their text does mention the words “double-gear extrusion”, so perhaps there is another gear behind the first one in the animation instead of a simple friction wheel. ]

Why are the processors only 32-bit? Other high speed systems I’ve seen normally use 64-bit processors to enable the system to keep up with the rapid motion system calculations required at high speed.

Anker is a major company with a huge following. Their marketing mojo will certainly attract many new people to the technology of 3D printing, but AnkerMake will have to ensure these folks have a good experience. If there are problems — and there usually are with 3D printers — then there could be trouble ahead. Does the M5 truly have a handle on how to introduce the tech to newbies? I have yet to see a low-cost provider do so.

AnkerMake M5 Thoughts

The M5’s retail price will be US$759, but it is now available on Kickstarter for a discount launch prices starting at US$429 (sold out). As of this writing AnkerMake has collected over 5,000 backers, making this one of the most successful 3D printer Kickstarter launches ever, and making Anker a player in the space.

Via AnkerMake and Kickstarter

You should do an update to this soon, they added to the Kickstarter the V6 Color Engine that will automatically spool multiple colors in.