SPONSORED CONTENT

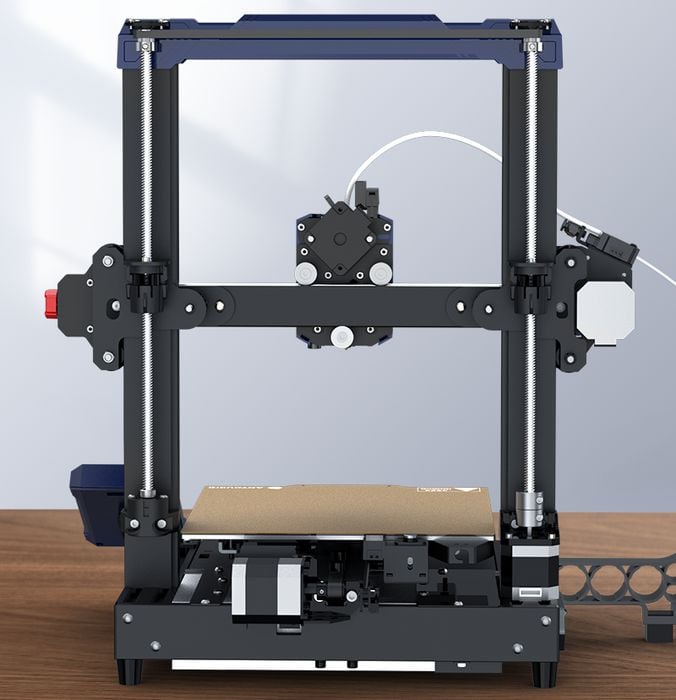

Anycubic’s latest FFF 3D printer, the Kobra 2, offers two unique technologies.

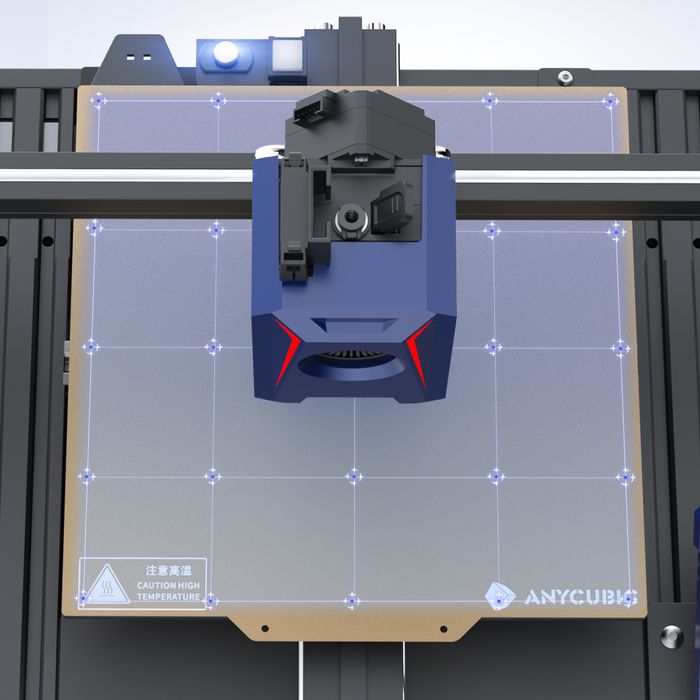

In a bid to simplify 3D printing and amplify user experience, Anycubic has launched its advanced LeviQ 2.0 auto bed leveling system.

Leveling and Calibration

FFF 3D printers require the first layer of each print job to properly adhere to the print plate. If not, then the job will inevitably fail one way or another. One way to ensure success is to “level the bed”, which is done by measuring the topology of the print surface at a series of points.

These measurements are recorded and then used to compensate for movements when the first layer is laid down. This process usually ensures the first layer is properly attached.

There are many different methods for measuring the topology, but usually, it’s done with a mechanical sensor. In some cases, it’s done manually by the operator using a feeler gauge.

By streamlining the calibration process and enhancing the quality of the first layers, auto bed leveling technology significantly reduces users’ frustration and setup time compared to manual bed leveling.

Background on Anycubic and its Technology

Anycubic’s latest offering, the Anycubic LeviQ 2.0 auto bed leveling system, is their most advanced leveling technology. This system embraces the trend of auto bed leveling, which has been gaining popularity in the 3D printing community.

LeviQ 2.0

The Anycubic LeviQ 2.0 auto bed leveling system employs an inductive sensor that generates a magnetic field and is able to detect interference within that field. This ingenious method allows the sensor to identify gaps or distances on metal surfaces without needing direct contact, making it adept at calibrating the topology of the print platform.

But the real game-changer is the integration of a smart z-axis offset module. With this, the LeviQ 2.0 can independently adjust the height of the nozzle and achieve an accurate Z-offset, making the leveling process a breeze, particularly for novice 3D printer operators.

Anycubic is already leveraging this new tech in its soon-to-be-released Kobra 2 3D printer. This integration will help users reduce their setup time significantly, providing an even smoother printing experience.

LeviQ 2.0 Implications

This announcement from Anycubic demonstrates a good understanding of novice 3D printer operator needs. The LeviQ 2.0 auto bed leveling system has the potential to simplify 3D printer operation by making the technology more approachable and user-friendly, especially for beginners.

With the additional feature of the smart z-axis offset module, Anycubic is not just automating but also intelligently simplifying the calibration process. The inclusion of this system in their upcoming Kobra 2 3D printer suggests we can expect more use of LeviQ 2.0 in future 3D printer models.

This innovative approach could force competitors to rethink their bed leveling strategies, potentially leading to the wider use of advanced leveling and calibration approaches in the industry.

But that’s not all. The Kobra 2 includes another new technology from Anycubic. This machine can 3D print at very high speeds, possibly up to 3X typical printer speeds. How is this accomplished? Anycubic has included these new hardware features in the Kobra 2:

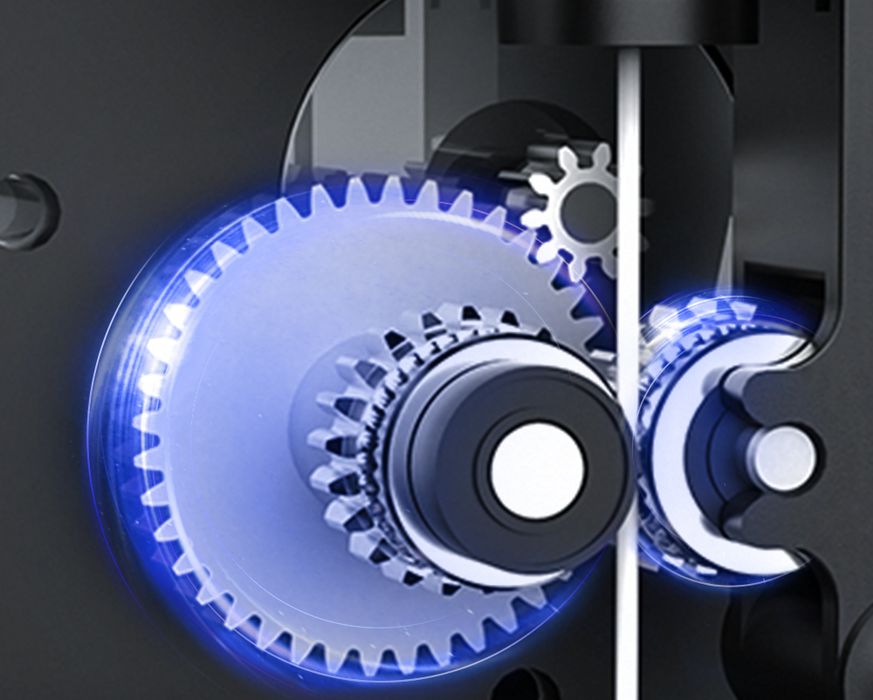

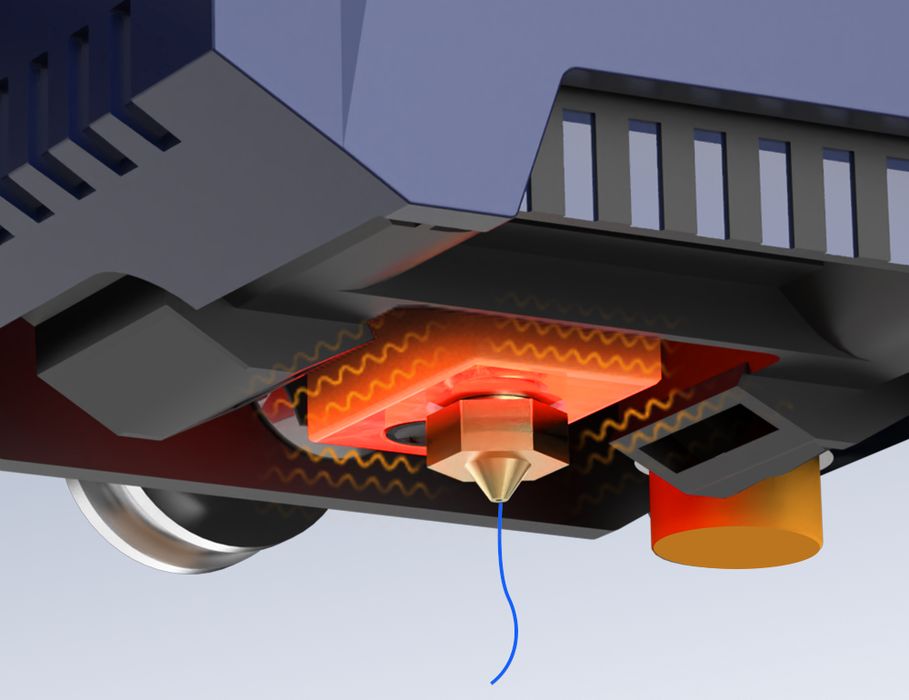

- New Dual-Gear Direct Drive Extrusion System: The direct drive extrusion system has a 4:1 gear ratio, which means it tightly grips the filament and prevents it from slipping, allowing for precise extrusion and flow control even when the printer is moving quickly. Moreover, a higher print speed necessitates a higher extrusion rate to compensate for slow extrusions during speed changes. Kobra 2’s 60W high-power hot end enables it to achieve this and melt the filament more quickly, leading to improved flow and higher print speed.

- Upgraded Cooling Fan: Equipped with a 4-watt cooling fan capable of 7,000 RPM, this component rapidly cools the filament post-extrusion, paving the way for quicker, precision-based layer application.

- Double metal spindles and SG15 bearings structure on the X and Y axes: This feature reduces friction between moving parts, allowing for smoother, faster movements, making it more wear-resistant than the traditional D shape wheel structure.

- Z-Axis with Double Screw Motion Mechanism: This mechanism can improve the speed of the Z-axis movement, reducing lifting resistance during the printing process, and keeping the X-axis level to minimize layer lines and achieve excellent results even at high speeds.

High-Speed Printing Analysis

Anycubic is pushing the technology envelope with its high-speed Kobra 2. By targeting the key components that directly influence printing speed, Anycubic has created a printer that not only speeds up the printing process but should also maintain quality and precision.

The Kobra 2’s high-speed printing capabilities may be useful for commercial operators who could benefit from the quick and efficient production of 3D-printed parts. There is also the possibility that this technology may motivate other 3D printing companies to speed up their own products, and that’s good news for everyone using the technology.

Via Anycubic