E3D-Online’s new Revo product set should make life far easier for FFF 3D printer operators.

Years ago UK-based E3D-Online introduced their V6 hot end, and changed desktop 3D printing forever. It was that component that dramatically increased reliability and extrusion consistency. Today their components are used by not only countless individuals building desktop 3D printers, but also by multiple major manufacturers of commercial equipment.

Now they are set to make another change, one that I hope becomes a de facto industry standard as their V6 did.

The RapidChange Revo series is designed to solve a very specific problem with desktop 3D printer operation: nozzle changes.

3D Printer Nozzle Swap

Today the nozzle is typically a small brass affair tightly screwed into the bottom of the hot end. By default, virtually all nozzle diameters are 0.4mm, and that’s what everyone mostly uses.

However, there is the possibility of swapping a nozzle for a larger or smaller nozzle. Smaller nozzles allow for much finer details to be printed, while larger nozzles coarsely dump material rapidly for fast prints. Two very interesting advantages for specific printing scenarios.

3D printer operators should use those alternate nozzles all the time.

But they don’t.

Why don’t they? Because, simply put, changing 3D printer nozzles is a huge pain in the a**.

The problem lies in the gap between the nozzle and the hot end: there shouldn’t be one, and if there is, high-pressure molten polymer will squirt through and totally mess up your hot end.

The standard practice is to finger tighten the new nozzle, then heat up the hot end to operating temperature, finally tightening the nozzle with a wrench. The heat is required to ensure there are no gaps at temperature, which could differ from the cold scenario. You absolutely must do this, because leaks could very easily destroy your entire extrusion system.

Heating and cooling delays aside, changing the nozzle is usually tricky. You need two suitably sized wrenches: one for the nozzle and one for the heater block. Oh, and make absolutely certain your wrench does not destroy the delicate wiring on the heater block when forcefully twisting the wrenches. Also make sure you don’t burn your fingers on hot nozzles, and place a block of wood on top of your print surface to avoid melted spots if a hot nozzle is mistakenly dropped. And if that’s bad enough, try doing all this if you are mechanically challenged or disabled in some way. [Note: I have burned my fingers many times]

I think you get the idea. Changing nozzles is most definitely something to be avoided. Because of those problems, myself and most other 3D printer operators simply never change a 3D printer nozzle unless it’s broken. We never get the benefit of fine details or fast printing that would be possible with other nozzles.

But that’s all set to change with the RapidChange Revo system.

RapidChange Revo

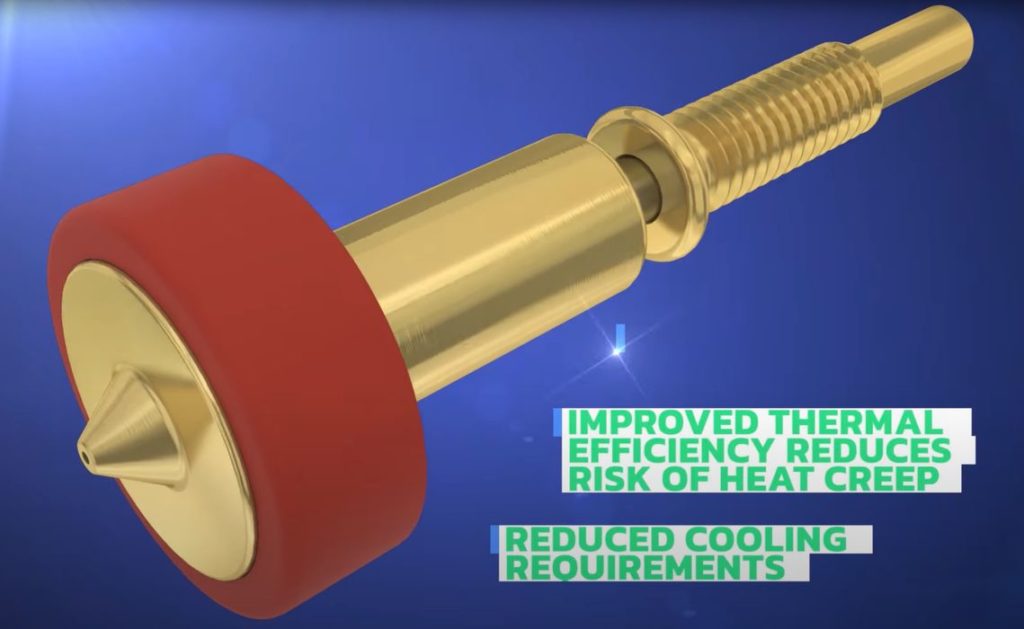

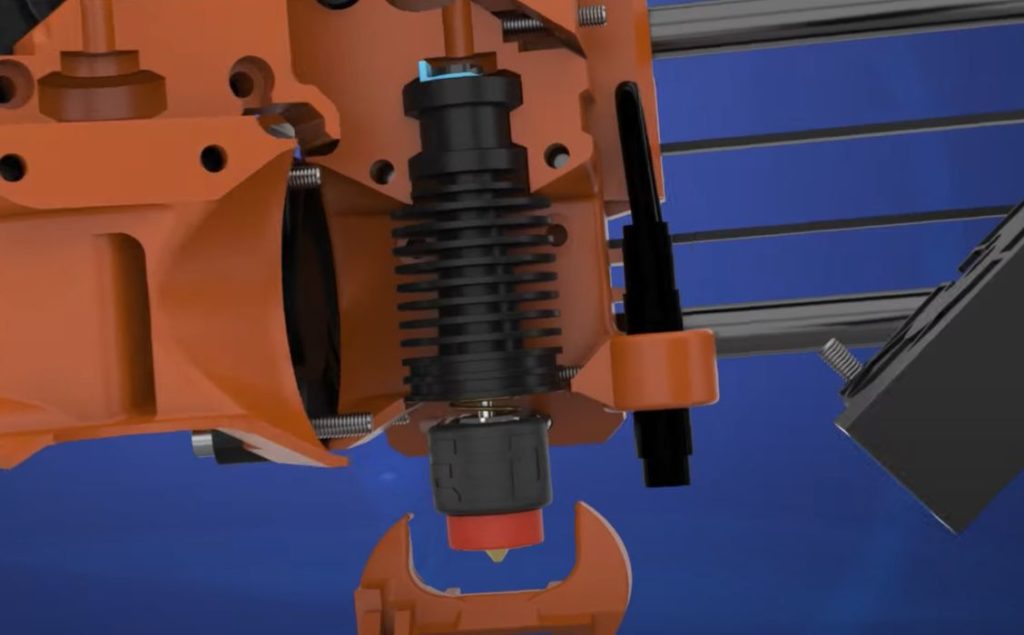

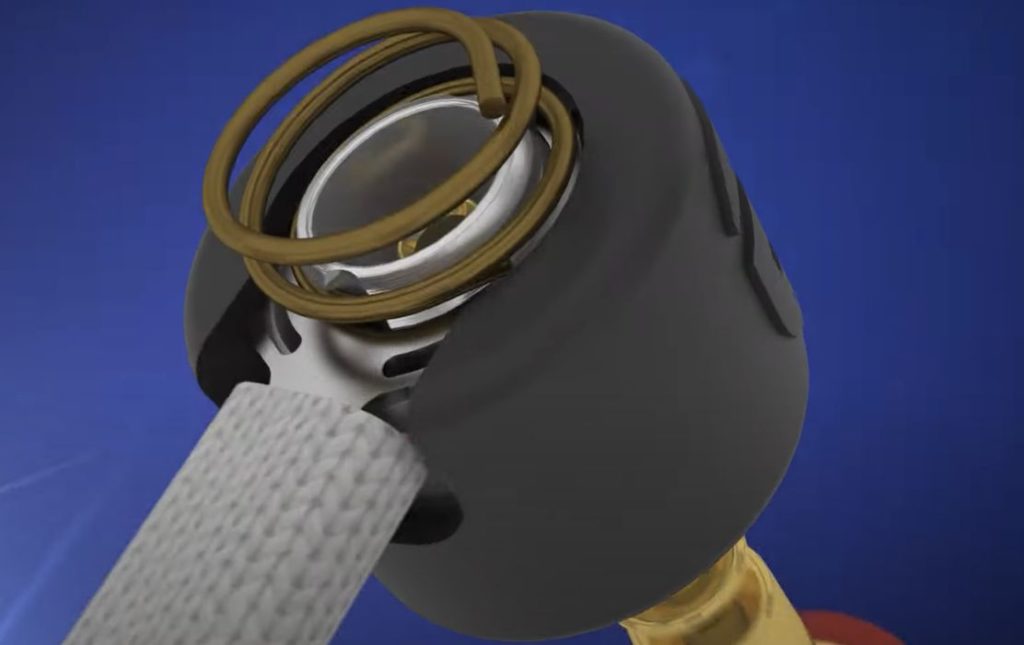

The core concept is that they’ve merged the hot end and nozzle into a single unit. This completely eliminates the gap that causes all the issues described above. You simply screw in the Revo unit with your fingers at room temperature, just like any other component on the device.

This makes it particularly simple to change nozzles: just unscrew it and put in a different one.

E3D-Online has made this convenient by launching a series of Revo nozzles of different diameters, currently including: 0.25, 0.40, 0.60 and 0.80 mm. Each is brilliantly colored coded by means of a silicone sock for easy identification.

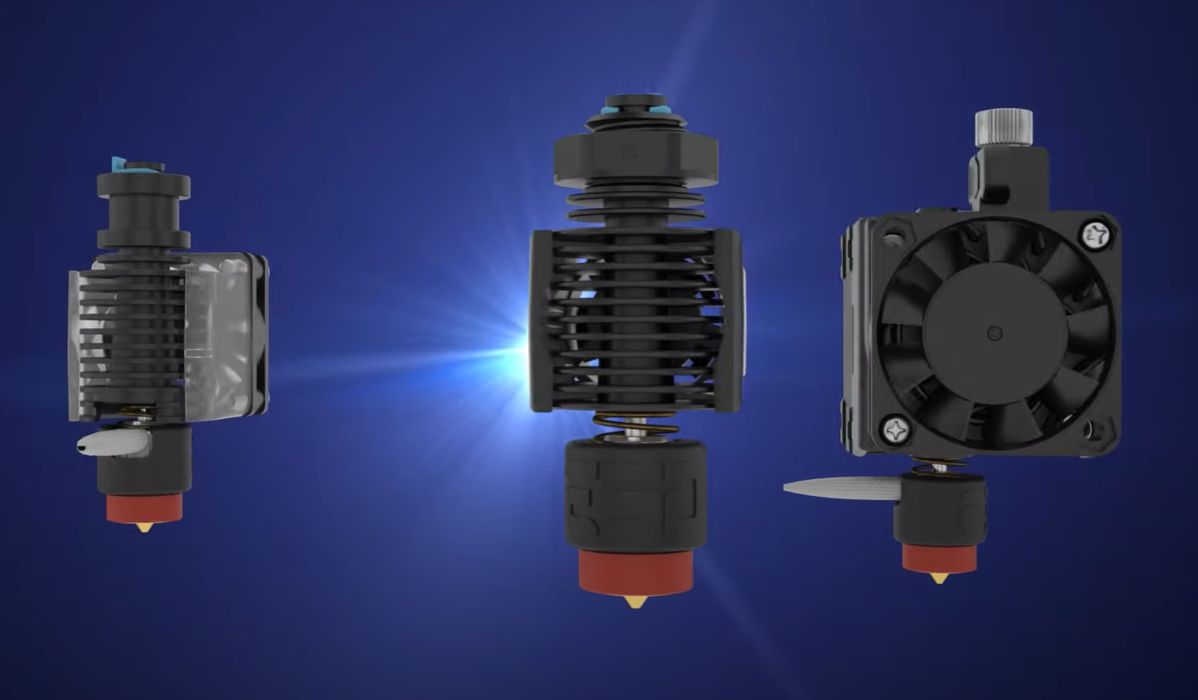

Of course, the mounting system must be changed to account for the new Revo hot end / nozzle. The company has therefore issued new “Revo compatible” versions of their V6, Hemera and Micro extrusion systems. With these the color-coded nozzles can be easily installed and interchanged. Even better, the Revo V6 is “drop in compatible” with existing V6 systems, so it should be very easy to switch to Revo.

I should also point out that the Revo system also makes clogged nozzle repairs just as simple: just replace it.

There’s another couple of very interesting changes on the Revo system.

First, the heating system has been redesigned to fully surround the hot end in a balanced manner. There is no chunky heater block, and E3D-Online has designed it to use less power when possible.

Finally, the Revo design is made to be far cleaner than earlier designs. The days of getting leaks covering the top of the heater block with polymer that burns and corrupts prints later are long gone. The circular design should be a breeze to deal with.

The new RapidChange Revo devices are not quite available yet, but you can pre-order them. E3D-Online hopes to ship them in March, so they are not that far away from being in your hands. For pricing, you’d best refer to E3D-Online’s web store, as there are quite a few combinations available to meet everyone’s needs.

Via E3D-Online