Charles R. Goulding and Andressa Bonafe examine the increasing 3D print activity in Florida.

Over the past decade (2010-2020), Florida’s population increased by 14.6%, at double the nation’s overall growth rate. With over 21,5 million residents and more than 100 million visitors a year, the State attracts people and companies with much more than good weather and natural beauty. A favorable business environment, including tax incentives and innovation, has allowed for the emergence of a $1 trillion economic hotspot that promises to keep growing.

Representing what could be the world’s 15th largest economy (if it were an independent country), Florida offers a wide range of opportunities across various fields. The 3D printing overview presented in the next sections includes some of the most recent and exciting developments in the State.

Major Cities

The Covid-19 pandemic has accelerated businesses’ relocation to Florida, particularly in the financial and tech industries. For instance, ARK Investment Management LLC made a permanent move from New York City to St. Petersburg, Florida – in a somewhat unique strategy given that its destination home is a designated Innovation District.

As companies flock to the Sunshine State, its four largest cities become hubs for growth and innovation.

Located in the Northeast, Jacksonville is the State’s most populous city and the largest one by area in the continental U.S. It is a global, multi-modal logistics hub centered around deep-water ports that provide same-day access to more than 94 million consumers. Prime infrastructure, access to talent, and a competitive business environment have attracted companies from various industries, including advanced manufacturing, financial services, health and biomedical, and IT.

Leading advanced manufacturers, including Johnson & Johnson Vision, Anheuser-Busch, BAE Systems, Baker Hughes, Medtronic, and Northrop Grumman have operations in the Jacksonville region. Many of these companies have relied heavily on 3D printing. Baker Hughes, for instance, recently announced a 3D printing joint venture with Würth Industry of North America, (a subsidiary of Germany-based Würth, the world’s largest fastener company) to provide 3D-printed replacement parts for products in the oil and gas industry.

Miami, the State’s second-largest city, is among the top urban areas in the country. Home to a diverse and vibrant arts scene, it is a major center of commerce, culture, and entertainment. Its Civic Center attracts a growing number of research institutes, medical centers, and biotechnology companies along with a talented workforce.

Miami’s world-class art and design events have showcased innovative 3D printing applications. In its 17th year, the international design fair Design Miami included among its highlights the Rock.01 sink, by Daniel Arsham in partnership with Kohler. The unusual piece resembles a rock formation and is made using additive manufacturing.

As the third-most populous city in Florida, Tampa boasts a diverse economic landscape that includes tourism, healthcare, finance, insurance, technology, construction, etc. The city has been home to some innovative applications of 3D printing, among which efforts at the Tampa General Hospital (TGH) stand out. Early in the pandemic, a team developed 3D-printed nasal swabs that are now used all around the globe. More recently, TGH doctors have been using CT scans to print exact models of patients’ organs that help improve surgical techniques.

In the State’s capital, Tallahassee, 3D printing is also finding new and exciting applications. In 2021, the first 3D printed house began construction in the Griffin Heights neighborhood. Similar to other projects developed abroad, this initiative aims to bring affordable housing to those in need. Florida-based startup Printed Farms and Precision Building & Renovating are responsible for the project, which utilized Danish manufacturer COBOD’s construction 3D printer. Capable of fabricating highly complex structures, COBOD’s BOD2 printer illustrates the ongoing revolution in the additive manufacturing of concrete.

Major Universities

The main educational institutions in Florida are also deeply involved in 3D printing. The University of Florida, for instance, has multiple additive manufacturing resources, including the Infinity Fab Lab at the College of Design, Construction, and Planning and a state-of-the-art 3D printing and rapid prototyping lab at the Department of Mechanical and Aerospace Engineering. These resources have allowed for a myriad of innovative applications, from prosthetics, adaptive controllers, and toys to solutions for managing extensive veterinarian fractures.

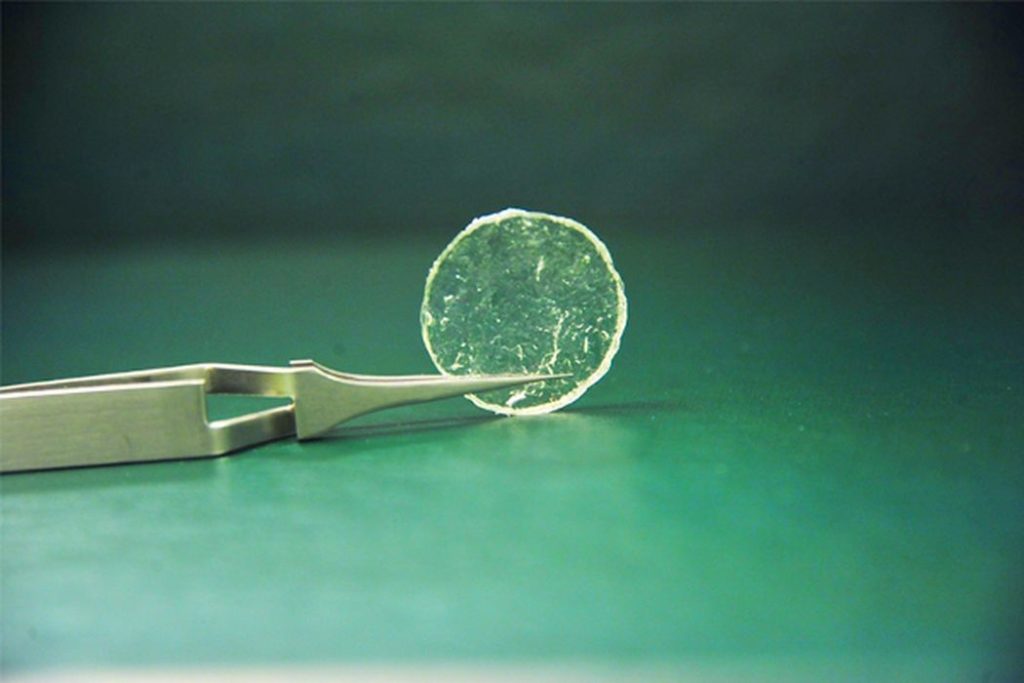

At Florida State University, research has helped advance 3D printing materials and applications. Researchers at the FAMU-FSU College of Engineering developed a theoretical model that explains the flow properties of vitrimers, a class of polymers that combine the strength of thermosets and the flexibility of thermoplastics. The model is expected to help manufacturers and recyclers come up with new ways to use the material, potentially expanding 3D printing applications.

An example of a polydimethylsiloxane vitrimer synthesized in the Ricarte Lab:

Home to the Johnson & Johnson 3D Printing Center of Excellence Collaborative Laboratory, the University of Miami has been at the forefront of additive manufacturing innovation. Examples range from 3D-printed PPE for healthcare workers to affordable housing with 3D-printed concrete. The University is also involved in defense-related research and development. Aiming to advance the production of hypersonic weapons using additive manufacturing, the US Naval Surface Warfare Center Dahlgren Division (NSWCDD) recently announced a series of collaborations and research agreements with key partners, among which the 3D Printing Systems and Atomization Johnson & Johnson Center at the University of Miami.

Major sectors

When it comes to aviation and aerospace, Florida offers an invaluable combination: rich supply chain, highly-skilled workforce, and top connectivity. The State is home to the renowned Kennedy Space Center, Cecil Spaceport, and Cape Canaveral Air Force Station, along with 130 public-use airports and 20 commercial airports. It’s no wonder that it has attracted major players in the industry, including Boeing, Embraer, Lockheed Martin, SpaceX, Blue Origin, ULA, and OneWeb Satellites.

The 3D printing industry has made great strides with innovation that impacts design, production, and parts-replacement related aviation and aerospace. Top-tier suppliers have widely incorporated additive manufacturing processes in areas such as jet engines, seating, and embedded electronics, as well as space simulators, spacecraft, and satellites.

With a significant presence in Florida, Boeing is a particularly interesting example of how 3D printing leads to more efficient design and production processes. The roll-out of Boeing 777X in early 2020 with more than 300 3D-printed parts – particularly in the GE9X engines – is proof of the success resulting from the integration of additive manufacturing.

Yet another thriving sector in Florida, the outdoor recreation industry can also greatly benefit from 3D printing technology. Boats and recreational vehicles (RV), for instance, require regular service, numerous accessories, and replacement parts that often face supply chain shortages and disruptions. RVs, in particular, can integrate 3D-printed solutions for lighting, HVAC, pumps and filters, kitchens, etc.

Similarly, Florida-based outdoor sports companies can innovate with additive manufacturing. A recent partnership between Wilson and Azul 3D illustrates this trend. Their innovative 3D-printed pickleball paddles are disrupting the way that the game is played with two new designs – the Quiet Paddle and the Custom Core Paddle. While the first significantly reduces the sound from ball hits, the second is completely customized to fit a player’s style.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Florida R&D Tax Credit

Some companies that claim a federal credit could also qualify for Florida’s R&D tax credit program. The State provides a corporate income tax credit for eligible businesses for certain qualified research expenses. According to the Department of Economic Opportunity, to participate in this program the corporation must be in one of the following targeted industries:

- Aviation and Aerospace

- Cloud Information Technology

- Homeland Security & Defense

- Information Technology

- Life Sciences

- Manufacturing

- Marine Sciences

- Materials Science

- Nanotechnology

Conclusion

There is a myriad of reasons to conduct business in Florida, where opportunities abound. The State is strong on technology and innovation, including diverse applications of 3D printing. From aerospace to outdoor recreation, companies from a wide variety of industries can take advantage