Artec 3D released Artec Studio 16, along with a brand new cloud service.

The company produces high-end dedicated 3D scanning hardware and software used by industry. Recently we took a very deep look at one of their flagship products, the Artec Leo.

One of the key findings of our analysis was the strength of their software, Artec Studio. For those unfamiliar the tricky process of 3D scanning, the software is just as, if not more important than the scanning hardware itself. Artec Studio is already a very powerful tool, and the latest release adds some intriguing new features.

Artec Studio 16 Features

The main theme of release 16 seems to be “speed”, as several functions have been dramatically sped up. This is quite important because of the magnitude of file sizes in 3D scanning. Essentially, to get the most detail in a 3D scan you will require processing vast quantities of data collected by the scanning device. It’s therefore quite important to speed up operations because scan processing typically involves “going for coffee”.

For example, in release 16 project files now load 10X faster. That might not seem notable, but it is when considering the size of the files involved.

Artec Studio 16, as its predecessors, is able to use what Artec 3D calls “HD” mode. This is software-powered feature that somehow squeezes more detail out of a captured 3D scan. In my testing of the software, I found HD processing to be the most time-consuming step. Now, however, Artec 3D said release 16 processes HD mode files “nearly 2x faster”. That’s very good news for those requiring incredibly detailed 3D scans.

Another feature improvement is the Scan-to-CAD function, where a raw 3D scan is converted into CAD components to reverse engineer an object. Artec 3D has made a number of workflow enhancements to speed this activity. In addition, there are now primitive objects that can automatically “snap” to your 3D scan to begin the reverse engineering process.

Artec Cloud

For me, the biggest news is the announcement of the new “Artec Cloud”. This is a cloud-based system that enables a number of interesting new workflows. Artec 3D explains:

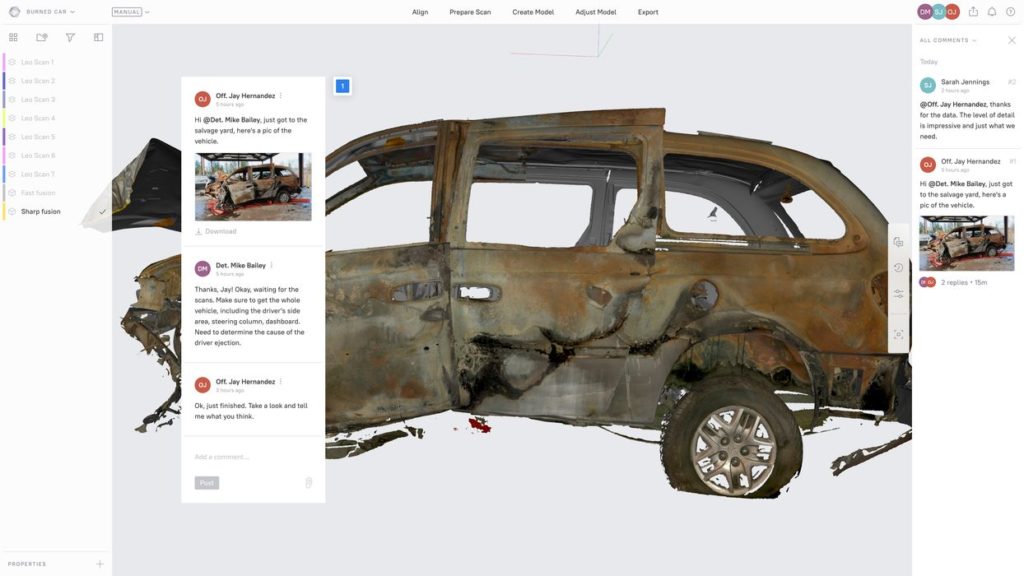

“Artec Cloud (is) a collaborative platform that allows users to access, view, comment on, and process 3D scan data online. The integration of AS16 and Artec Cloud streamlines 3D project management. Users can upload and share 3D data with peers, leave comments, send photos, and have full conversations. With Artec Cloud, users can also process 3D scans in their browser from any location and from any computer, without being constrained by the technical limitations of their devices.”

That last point is very important: 3D scanning very often requires the use of high-powered — and expensive — laptops equipped with fancy graphics cards. By enabling processing to take place in the cloud, this constraint has been removed and, guess what, your 3D scan processing is sped up again.

There’s more to this: instead of having individual scanner operators buy and occasionally use graphics cards, the cloud service could make much more efficient use of that increasingly hard-to-get hardware.

The cloud service could be updated, expanded, sped up and more, without any intervention of Artec 3D users. It is also possible Artec could leverage the centralized processing power to provide additional functions they haven’t been able to provide up to now.

It seems that any Artec 3D equipment owner should immediately consider upgrading to Artec Studio 16 and take advantage of the new functions and cloud service.

Via Artec 3D