There’s been a very interesting development in Bambu Lab’s A1 recall process.

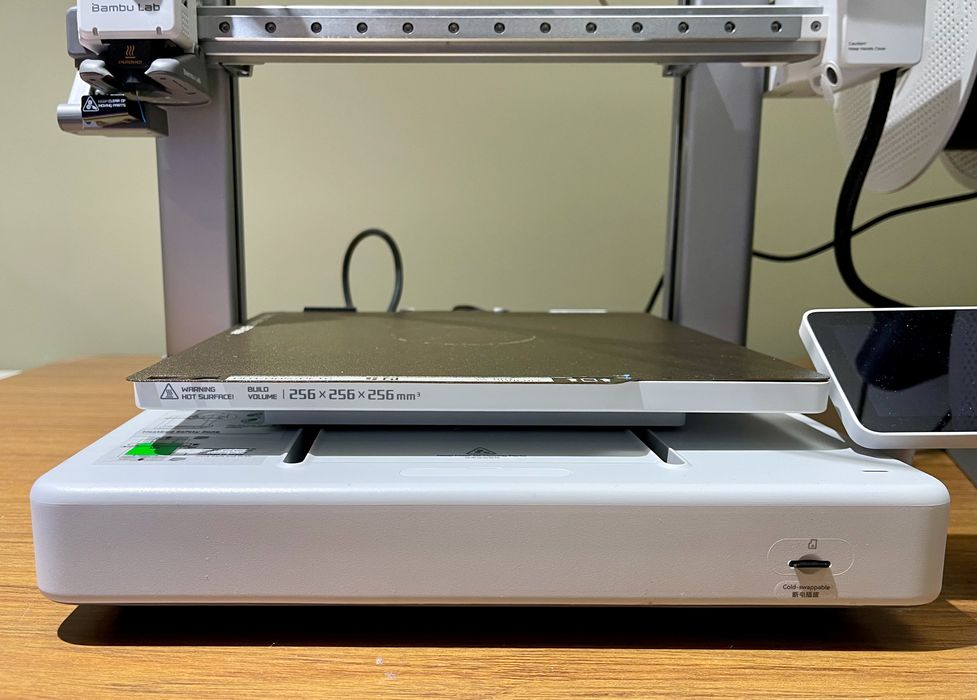

Readers may recall that about a week ago Bambu Lab issued a notice that it was possible for the heat bed cable on A1 3D printers to become damaged. While the cable works fine while printing, the damage occurs if the cable is mishandled. For example, if the A1 is tipped on its back causing the cable to bend sharply.

If damaged, the high power flowing through the cable could short circuit and cause a fire. There have been a couple of documented incidents of this happening.

Bambu Lab stepped up immediately and notified all users of the situation immediately and provided an interim fix: a 3D printable strain relief cover for the end of the cable. While that would prevent some damage from happening, the rest of the cable could still be damaged if mishandled.

The company then announced a full recall of the A1, no doubt fearing future damage from operators mishandling the cable. They offered the ability to return the device, or wait for a special upgrade kit to replace the cable. They offered store gift certificates as compensation for the problem.

All of this is unprecedented in the desktop 3D print world. Several previous manufacturers have had far worse problems and never acknowledged them, and I believe the A1 recall is the first in 3D print history.

While there is an ongoing recall, some operators persist in using the equipment, believing they are not at risk if they don’t damage the cable. They’re probably correct, but Bambu Labs cannot control operator usage and could be liable should anything bad happen in the future.

The new development is that apparently a recent firmware upgrade to the A1 introduced special code to handle the damage.

Some operators are reporting their machines become “bricked”. Others say their A1s continue to operate properly.

It seems that the new firmware could be set to disable the A1 if any unexpected sensor readings are detected with the heat bed. This is precisely what would happen if the cable was damaged.

One operator wrote that their machine was disabled after pausing a job in mid-print. Evidently the pause resulted in a thermal change on the bed, which the firmware interpreted as a problem. This triggered the disabling process.

It seems to me that this is a very prudent measure taken by Bambu Lab, as it would sharply reduce the number of potential incidents that might occur while the recall is ongoing.

Then Bambu Lab responded:

”Please note that this is not a “printer lock” but an additional safety feature for the A1 printers to protect all our users from any danger.

The heatbed temperature is carefully monitored and if there’s any change in temperature which is not as expected, a software fuse is triggered to avoid any danger for the user.

This is not a way to lock the printer, it just stops the heatbed from heating, temporarily.

The heatbed can be enabled again with a simple file that is run by the printer, but we strongly recommend against using this file if the software fuse is triggered.

We will share a detailed Wiki article shortly where everything will be explained in detail.

I would also like to mention that this is done because we put our customer’s safety first, and we strongly recommend everyone to stop using the A1 and read our A1 Recall Update blog post, then follow the instructions listed there.”

Locking out a 3D printer, even temporarily, is not going to sit well with some operators that depend on their equipment and might not have an alternative 3D printer handy. On the other hand, if a company is aware of a potentially damaging issue, they should do everything in their power to avoid incidents.

That’s exactly what Bambu Lab is doing here. While some operators are not happy, it is what it is, and I believe Bambu Lab is doing what should be done. In properly run factories and workshops there are always lockout-tagout procedures to deal with damaged equipment.

In any event, the recall process — either machine replacement or cable replacement — will be completed in a reasonably short time. After that, things will be back to normal.

Via Reddit