The update brings significant enhancements in material compatibility, user collaboration, and printing flexibility to the Bambu Lab ecosystem.

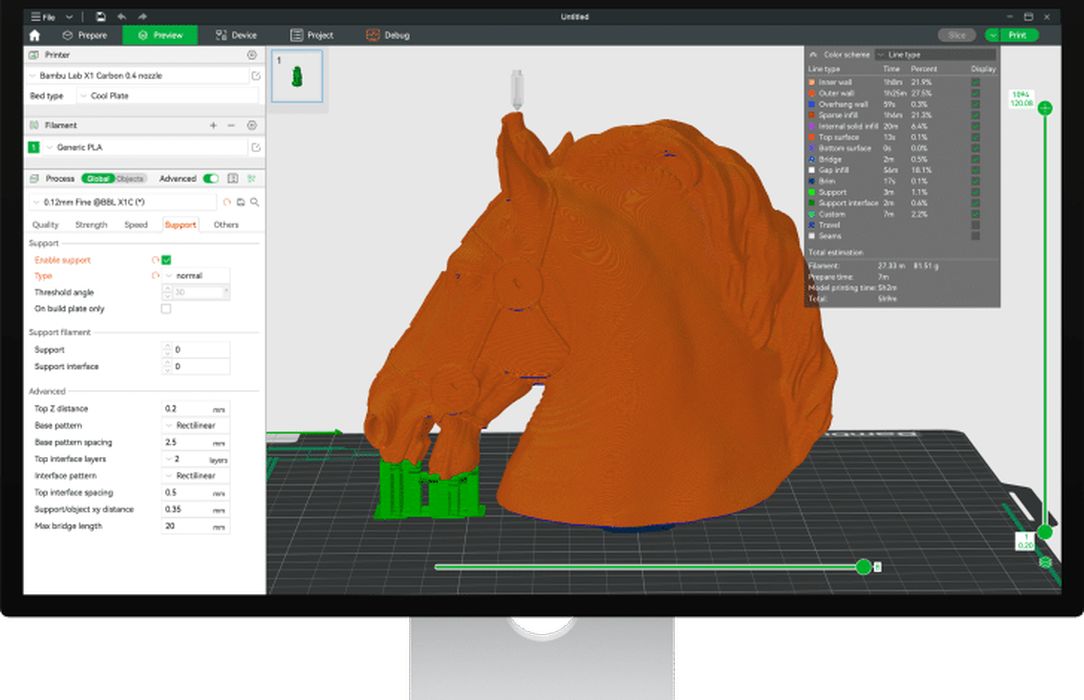

Bambu Studio has released version 1.8.2 – offering new 3D printing capabilities by enabling true integration of third-party filaments into the Bambu Lab ecosystem. This latest version offers significant enhancements in material compatibility, user collaboration, and printing flexibility.

Key highlights include third-party material integration, with users now able to easily assign third-party materials to AMS units – particularly advantageous for multi-material printing with non-standard materials, expanding the creative possibilities for designers and hobbyists alike; and access to community-driven material profiles by allowing the download and sharing of third-party filament and processing profiles – mirroring the material marketplaces of UltiMaker, Raise3D, and Fusion3, simplifying the learning curve for handling non-standard materials.

Innovative features

Innovative features

Features include custom filament creation, where users can set up their unique filament profiles directly in the software – eliminating the previous limitations and troubles associated with AMS mapping; support for custom third-party printers, with users now able to create printer presets automatically – a major improvement over the manual adjustments required previously; supports for the export and import of printer, filament, and process profiles – offering greater flexibility and ease of use; support for Bambu A1 printer; an automatic flush volume calculation feature to optimize multi-color printing and eliminate filament waste; and several user experience enhancements including no popups when sending to print, automatic object arrangement on the plate, and a new connector function in split tools.

Notable improvements

Bambu Lab’s platform now boasts improved auto lift type detection – reducing gcode export time significantly; nozzle diameter and hardness detection to ensure the compatibility of the nozzle with the selected filament – reducing the risk of clogging and wear; enhanced support for device file management for P1P, P1S, and A1 mini printers; improved display of black models and the addition of Tree Organic as a new support style; and the inclusion of features like improved patch connections in multi-material painting, model search by name, an ‘Auto Bed Type’ function, and more.

Read the rest of this story at VoxelMatters