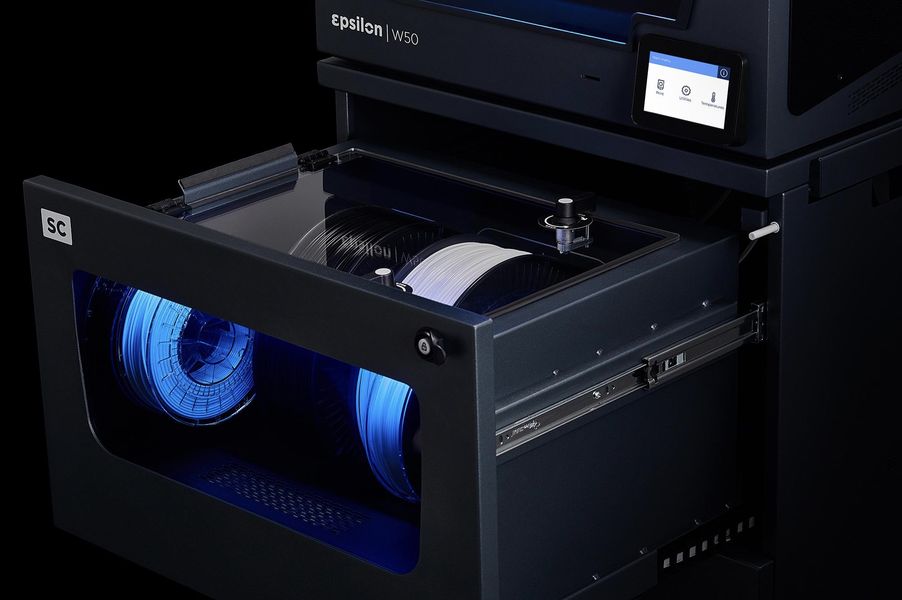

BCN3D announced a new “Smart Cabinet” accessory to accompany their Epsilon workbench 3D printers.

The Smart Cabinet is a device to store spools of 3D printer filament, but condition them when doing so. Specifically, the Smart Cabinet is designed to maintain particular humidity levels for the materials.

For some engineering materials, low humidity is a serious concern. Some materials are quite hygroscopic, meaning they can easily absorb moisture from the ambient air if stored without regard to conditions.

This absorbed humidity comes into effect when 3D printing is attempted: the water essentially boils when pushed through a 3D printer’s hot end, causing a bubble to appear in the material flow. These bubbles can corrupt the smooth surface of the print, destroy the optical properties of translucent materials or dramatically weaken the strength of a print — because air is a lot less strong than material.

The normal solution for these problems is to store the material spools in sealed bags with desiccant to absorb any moisture. However, for high-level production, that’s simply not sufficient and better solutions are required.

Some companies have produced dryer solutions where spools are stored in an enclosed manner, and the humidity levels are precisely maintained. That’s the goal of BCN3D’s Smart Cabinet.

The Smart Cabinet is one of many similar devices on the market, but it has a couple of very interesting twists that differentiate it from others.

Dryer With UPS

First, it includes a UPS, or uninterruptible power supply. The UPS will continue to provide power to the unit during a temporary power outage.

Normally you’d think a UPS would be best used on “active” equipment, rather than a static spool storage cabinet. But in fact the UPS is highly desirable.

Some 3D print materials are extremely hygroscopic, meaning they can very quickly absorb moisture from the air, even in a matter of a couple of hours. For some applications, this could effectively destroy the job quality, so it is of the utmost importance to constantly ensure the store of materials is kept dry. That’s the job of the UPS, a feature not normally found on drying cabinets.

Adsorption Dryer

The second interesting feature is the method of drying. BCN3D has chosen to use an adsorption process. This process involves using an amount of desiccant, in this case it’s alumina pellets, to absorb moisture as air flows through the pellets.

However, desiccants eventually get “full” and no longer absorb moisture. They must be replaced. Some drying cabinets require you to swap desiccant periodically, and in these cases it’s possible for someone to forget to do so. And then you’ve wrecked the stored filament again.

The BCN3D Smart Cabinet’s adsorption process includes a “regeneration cycle”, in which the system occasionally blows hot air over the desiccant to “empty” it of moisture. Once done, the system reverses and again provides dehumidified air for the enclosed chamber.

This process means that you will never have to swap the desiccant, as it will be constantly renewed. The adsorption process also allows very low levels of humidity to be achieved, which can more rapidly dry a new spool in the air-tight Smart Cabinet.

BCN3D’s CTO, Eric Pallarés, explains:

“The Smart Cabinet draws attention to the important fact that, in order to get fine, repeatable parts, it is crucial to control the whole printing process, which includes ensuring the materials are in optimal conditions. All materials are sensitive to humidity to a certain degree, but some of them, like PA, TPU, or BVOH are especially affected by it. For example, on a humid day, a spool of PA can absorb the amount of water that makes printing issues appear in a few hours, in less than a day… When customers struggle printing PA, wasting time and money on failed or defective print jobs is not because of the printer, or because of the profiles, but because of the degradation of the materials. So to really unlock the potential of AM with technical materials, beyond PLA, a solution like the Smart Cabinet is mandatory.

In addition, as the 3D printers increase in terms of volume, the printing times also grow… so in industrial or lab contexts, where power outages or micro-cuts are quite frequent, the Smart Cabinet offers life-saving protection to reduce waste and improve efficiency. As a result, any customer aiming both with technical materials will benefit from this new product. It should be noted that in the filament PA, for example, some mechanical properties improve by 20% with the use of the Smart Cabinet,”

The introduction of the Smart Cabinet accessory will no doubt increase the attractiveness of BCN3D’s Epsilon series, particularly with manufacturers requiring consistent production of high-quality parts.

Via BCN3D