Evidently BCN3D has struck gold with their new VLM 3D printing process.

VLM, announced earlier this year, is an entirely new 3D printing process, and certainly vastly different than the FFF processes used by BCN3D up to that point.

VLM, or “Viscous Lithography Manufacturing”, is a resin process in which a transparent film runs through a bath of resin, and is then moved to the build chamber. The bottom of the film is wet with resin, and it’s cured with UV light. This process repeats layer-by-layer until the object is complete.

Apparently the VLM process can also be adapted to produce multi-material prints, presumably by having the film run through different material reservoirs. At top you can see an example of a multi-material part produced using VLM. Multi-material capability is something that extremely rare in any other resin system, and offers the possibility of using soluble support structures for complex resin prints.

Aside from the multi-material aspects, that might sound like a slightly different approach for resin 3D printing, but the mechanics of the VLM process allow for the use of highly viscous resins.

Most other resin 3D printing processes require thin resins because they must be jetted through tiny nozzles or must quickly flow into position for new layers. Viscous resins cannot do those things.

What’s the big deal with viscous resins? All resins are a mix of photoinitiators and other additives to form the resin and subsequently the solidified object. Additive can be used to create different colors and more importantly different engineering properties. For example, adding a high ratio of reinforcing material could develop a very strong printed object.

The ability to use viscous resins opens up the possibility of creating miracle resins with all kinds of properties not currently present in today’s resin 3D printing processes.

That sounds quite interesting, and apparently it has caught on with industry. BCN3D now reports they have no less than 500 companies applying to be “early adopters” of VLM. That’s a significant amount of participants for something no one’s really seen yet.

What will BCN3D do? They explain:

“BCN3D has responded to the demand by partnering with Arkema and Henkel to obtain material properties and applications otherwise unreachable with other resin-based technologies, and by revealing its commitment to delivering VLM systems to 20 of the companies currently enlisted in its Technology Adoption Program during Spring 2023.”

Twenty is a lot less than 500, but this is an entirely new process and BCN3D is wise to start slowly.

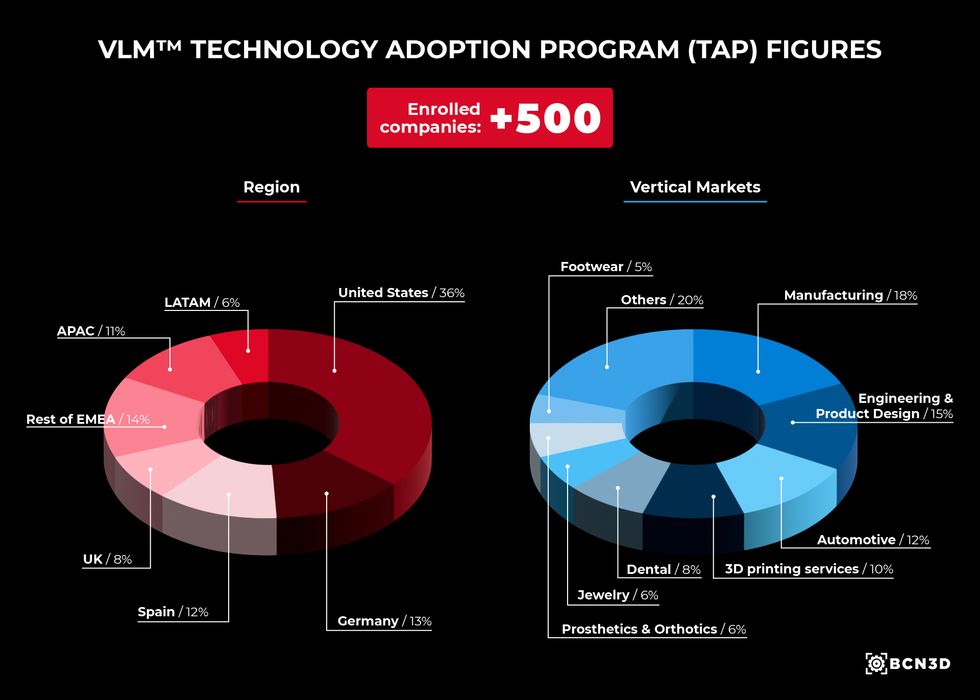

There were so many applicants that BCN3D actually did an analysis of them to find out who they were and what they intended to use the technology for. They produced this interesting infographic showing the results:

The most fascinating aspect of the survey is the breadth of industry interest. We can see automotive, dental, jewelry, footwear, prosthetics, manufacturing and prototyping — and there’s another 20% of other applications, too.

BCN3D elaborated on the applications suggested by applicants:

“Some of the main applications taken from this research include low emission end-use parts, elastomeric components, biocompatible parts, and the mass-customization of high-temperature and high-resistance parts. Furthermore, multi-property opportunities in the medical sector range from the need of different biocompatibility requirements in dental, to complex combinations of rigid and flexible parts in prosthetics and orthosis. Last but not least, regarding the mass production of functional parts, the obvious applications include nesting strategies with water-soluble supports without manual polishing or overmolding solutions. Among this wide variety of applicants are those participating in material development. These elite AM users are testing and furthering new ways to utilize the high viscosity resins that make VLM so unique.”

It’s rare that a new technology would appear applicable to such a wide array of industries and applications.

What’s next? BCN3D explains their strategy:

“BCN3D is selecting 20 elite customers to become the first to acquire these systems which will be installed in their own facilities during the spring of 2023. This will grant each company in-house accessibility while still maintaining continuous contact and support from the dedicated materials and applications engineers at BCN3D that make up the application development service.”

It seems that BCN3D has a tiger by the tail.

Via BCN3D