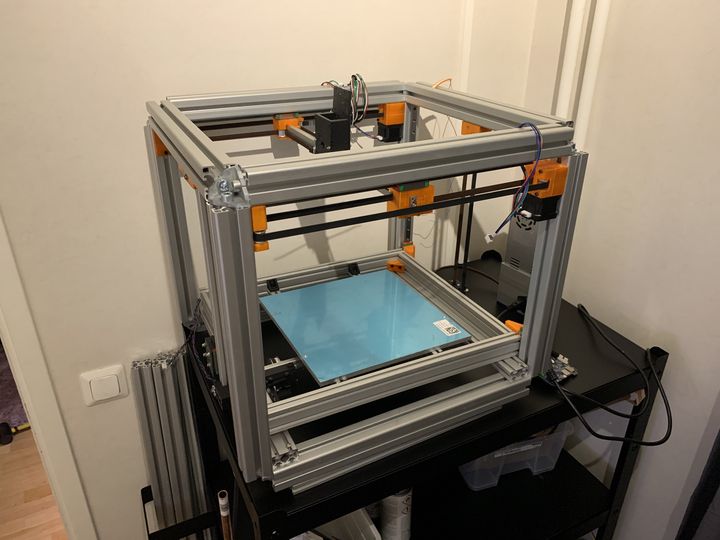

There are plenty of open source designs for 3D printers, but most of them are for relatively straightforward desktop machines. That’s not the case with Blackbox.

Blackbox is a project spearheaded by Frankfurt-based industrial designer Marc Schömann, who runs the site layershift.xyz. Schömann has previously designed 3D printers, leading to the Blackbox.

There is a clear gap in 3D printer capabilities in the market. At the low end, we see inexpensive desktop systems, sometimes without enclosures. While these can often produce competent prints, they are usually no match for more expensive devices that employ not only enclosures but more sophisticated mechanical systems, higher-end componentry, and advanced designs.

Unfortunately, these systems usually cost a great deal more than the inexpensive desktop units.

But there could be a way to get into that category with less expense, and that’s by building your own Blackbox 3D printer using its fully open source design.

Blackbox 3D Printer Specifications

The Blackbox offers a number of features that you might not find on an inexpensive open source 3D printer. These are some of the features I noticed:

- Large build volume of 300 x 300 x 275 mm

- Full enclosure

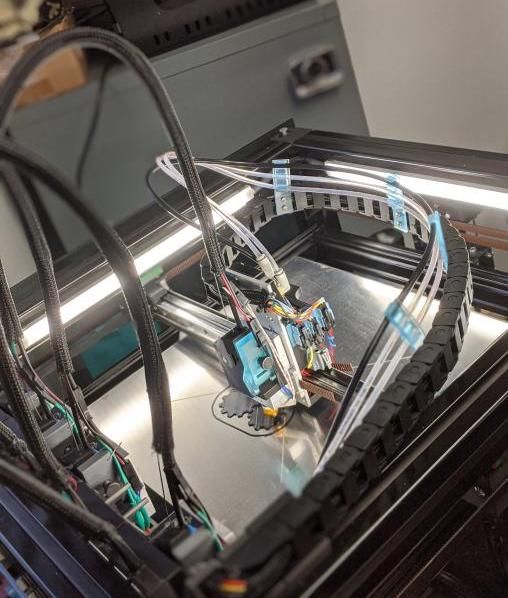

- Five-element toolchanger with direct drive

- Water-cooled toolheads (!)

- Belt-drive Z-axis

- Automated leveling and calibration

This is the only water-cooled option I’ve seen presented in open source form. Water cooling should enable more precise thermal control, and thus more reliable and consistent 3D printing quality.

The belt-drive Z-axis is a very interesting feature, as it allows for several different movements not always available in common directly-attached stepper motor configurations. You can move the bed more precisely, but also move it far faster. This is an excellent feature that hopefully will make me forget all those terribly slow bed raising and lowering experiences.

Blackbox 3D Printer Cost

To purchase a commercial 3D printer using water cooling systems, you could expect to pay a great deal of money. However, if you were to build a Blackbox from the open source plans with off-the-shelf parts you would likely save quite a bit of cash.

The Blackbox documentation says you can build a fully operational Blackbox 3D printer for approximately US$2,900. That’s a higher cost than inexpensive desktop systems, but far less than commercial equivalents.

On the other hand, you have to build the Blackbox yourself, and that’s not a task for everyone. The Blackbox documentation explains:

“Blackbox has some new (to most) design elements that will push you to learn about systems you may not have dealt with before. In general though, the recommendations from other DIY printer build communities translate well.

This probably shouldn’t be your first 3D printer. There are always exceptions, but the experience you have will likely lean on your previously acquired skills from using and maintaining other machines.”

The project is entirely online and provides extensive documentation, as well as the source files for all the Blackbox designs. Not only are the printable and CNC-able files provided, but you can also download the CAD design files in .STEP or Autodesk Fusion 360 formats. The Fusion 360 files in particular load with all parts linked into assemblies.

There is a detailed assembly guide, a dedicated private Facebook support group, and a real-time Discord server. It seems there will be plenty of assistance, should you need a question answered.

Like many open source projects, the Blackbox project posts their roadmap publicly in Kanban card form. Currently they’re working on improving the end-stop systems, as well as aluminum upgrades. One “idea” that hasn’t yet moved forward is the idea of using different types of tools, such as plotters, lasers, assembly grabbers, etc. This would fit well with the tool changing capability of the system and make it an even more powerful 3D printer.

If you’re interested in building a high-end 3D printer, the Blackbox could be a design to investigate.

Via Layershift and Dozuki

Thanks for the write-up Kerry!

We’ve (the small dev team) have been hard at work polishing the documentation, but are excited to implement all of the other tools in our roadmap.

In addition, we’ve teamed up with LDO Motors, Mandala Roseworks, and other trusted open-source community vendors to bring parts kits to those interested in building a Blackbox. The link to the store can be found in our Dozuki documentation and BOM.

I look forward to hearing from your readers!