A new material from FABULOUS has a very interesting property: its blue color.

The French company produces materials for 3D printing, including a line of resins, as well as a series of powders suitable for SLS 3D printing. The materials include nylons such as PA6, PA11 and PA12, and PP, with a TPU on their product shelf.

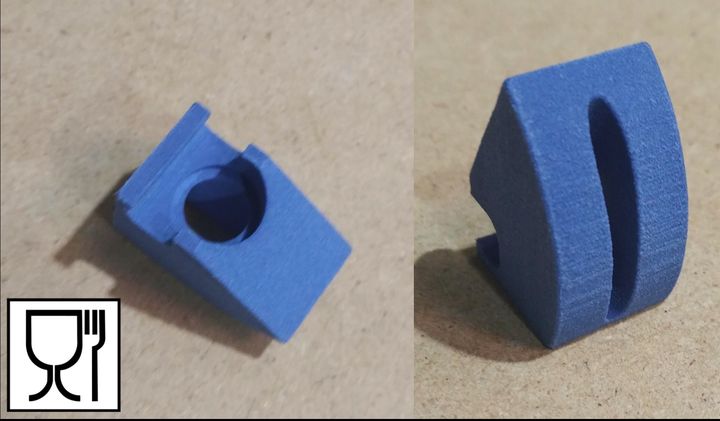

Their latest product is “BLUE CARE”. It’s a PA11 powder suitable for SLS 3D printers, and, as you might suspect, its color is blue.

BLUE CARE is targeted at the food industry and it has some unique properties designed specifically for that market.

One of the properties, as you might guess, is that BLUE CARE is certified as food safe. That’s a clear prerequisite for any material intended to touch edible products.

But there’s another property that’s designed for the food industry: the blue color.

What? Why would you need a blue color for the industry?

It turns out there is a very good reason for using blue. In fact, there is a very specific shade of blue that is used in the food industry: RAL 5005, also known as “Safety Blue”.

The food industry uses this particular color for plastic parts in food preparation equipment. The idea is that should a chunk of a plastic part break off and land in the food passing through the machine, it will be easy to visually identify. That’s because very few food products are naturally blue, and especially not “Safety Blue”. This can also be automated with optical sensors that look for that color.

Similarly, any organic contamination of Safety Blue parts can be more easily detected. For example, if mold is growing on a Safety Blue part it can be easily seen.

FABULOUS says that the specific blue obtained when 3D printing with BLUE CARE can be tweaked in post-processing:

“BLUE CARE parts have different colours depending on the post processing, directly after printing the colour presents RAL 5023 (Distant Blue), after chemical smoothing it’s possible to achieve the RAL 5005 (Safety Blue).”

Aside from the color, BLUE CARE is a PA11 material with the usual engineering properties aside from the blue color.

FABULOUS explains that can be used in not only SLS systems, but also in HP’s MJF systems and infrared 3D printers. However, it’s likely you’ll have to experiment with print settings to obtain optimal results.

With BLUE CARE material it should be possible to 3D print production-quality parts suitable for use in food preparation equipment.

This is quite a breakthrough, as it demonstrates how an industry might have been held back by the details of material properties. While 3D printer sales representatives would surely boast of the amazing capabilities of their equipment, the food industry would simply ignore all that unless it could be actually used with proper materials.

This shows the critical importance of material choice and how many more 3D printing applications can be lit up in the future.

Via FABULOUS