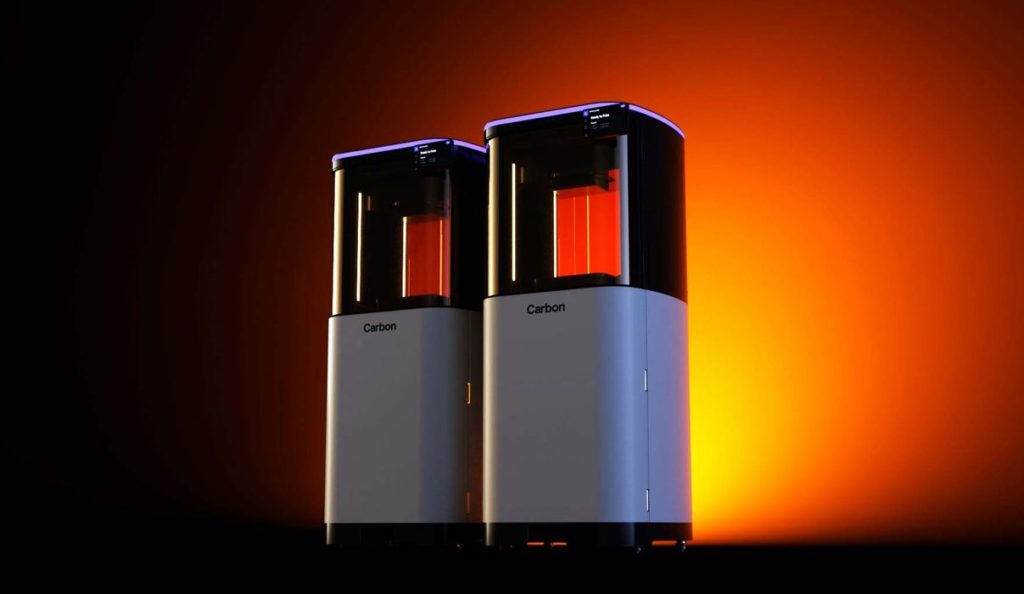

Carbon announced a two new DLS 3D printers, the M3 and M3 Max.

Following on from the M1, M2 and L1 models, the new M3 series is improved in a number of ways. The new technology is packaged in two models, the M3 and M3 Max.

The company has been improving their materials and software (via the recent release of their Design Engine) and now they have combined these with new 3D printing technology.

The new machines still use Carbon’s proprietary DLS process, in which a thin oxygen layer eliminates bonding to the resin window. That allows far greater speed of printing than in typical resin 3D printers, since there is no requirement to peel partial prints off the window on each layer.

Carbon’s Chief Product and Business Development Officer Phil DeSimone said:

“With these next generation printers — combined with our Design Engine software and Carbon DLS materials — design teams across business verticals can create high-quality prototypes with end-use performance quicker and more efficiently than ever before. And once the product development is complete, Carbon’s platform enables companies to move to production quickly and efficiently anywhere in the world. We believe this new generation of Carbon DLS technology will empower more collaboration and help to revolutionize how products are designed and made.”

While a number of specifications have changed with the M3, the key bits for me focused on quality and throughput.

For quality, Carbon has added closed loop controls on both temperature and force. These will be real time sensors that allow the machine’s controller to dynamically adjust those factors during each print. This should ensure far greater print quality as optimal conditions will always be present during printing. Carbon said this will greatly increase part consistency.

For throughput Carbon has done a couple of interesting things. First, the M3 model has a build volume of 189 x 118 x 326 mm, the same as its predecessor, the M2. However, faster print speeds means more part throughput for production can occur.

The M3 Max is double the build volume of the base model M3, and you might wonder whether Carbon has compromised print quality by doing so. Normally when a resin 3D printer is scaled up the size of the light pixels rises accordingly, lowering resolution. However, here it seems that Carbon has swapped in a higher resolution 4K light engine, which should compensate for this effect. Carbon said:

“The M3 Max printer offers double the build area with the same pixel size and density as the M3 printer, making it ideal for larger parts or producing many smaller parts with similar quality.”

Carbon also uses “next-gen DLS printing technology” in the M3 models. This new approach apparently uses far less force during printing, perhaps due to the closed loop processing. The lowered force enables more complex geometries to be attempted, and thus more applications. The process also produces measurably smoother surfaces, which should benefit companies using the equipment for end-use parts or products.

That’s quite interesting, because the company has always focused strongly on highly complex lattice designs; I’m wondering what kind of applications might be switched on with this tech.

One more thing: Carbon said:

“Thanks to better heat management, the printers deliver more throughput per square foot in thermally limited scenarios.”

I take this to mean that heating is engaged in a more optimal manner in the M3 models, and thus there is less heat leakage to the outside air. That might not seem important, but if you’re installing several M3’s in a production setting where there is limited HVAC, you must be careful not to exceed the thermal capacity of the room.

I am sure there are scenarios where older Carbon equipment was limited in number. For example, a room might be able to support only ten devices with their emitted heat. Meanwhile the new M3 devices might be able to squeeze a few more units into the same space without exceeding the room’s cooling capacity.

That’s very important because the cost of upgrading a large room’s HVAC could be considerable. The M3s could avoid that scenario entirely in some cases.

Carbon said the new M3s are now available for order, and would ship sometime after mid-year.

Via Carbon