Bambu Lab launched a new 3D printer series, the X1, designed for the prosumer market, and it has many features we’ve never seen before.

At first glance, the X1 appears to be a higher-end enclosed 3D printer, but it turns out this machine has an incredible array of features, many of which have never been seen on other equipment.

The X1 series is comprised of two models, the X1 and X1 Carbon. They’re the same except that the Carbon version is outfitted with a hardened nozzle and drive gear, as well as extra cooling capacity.

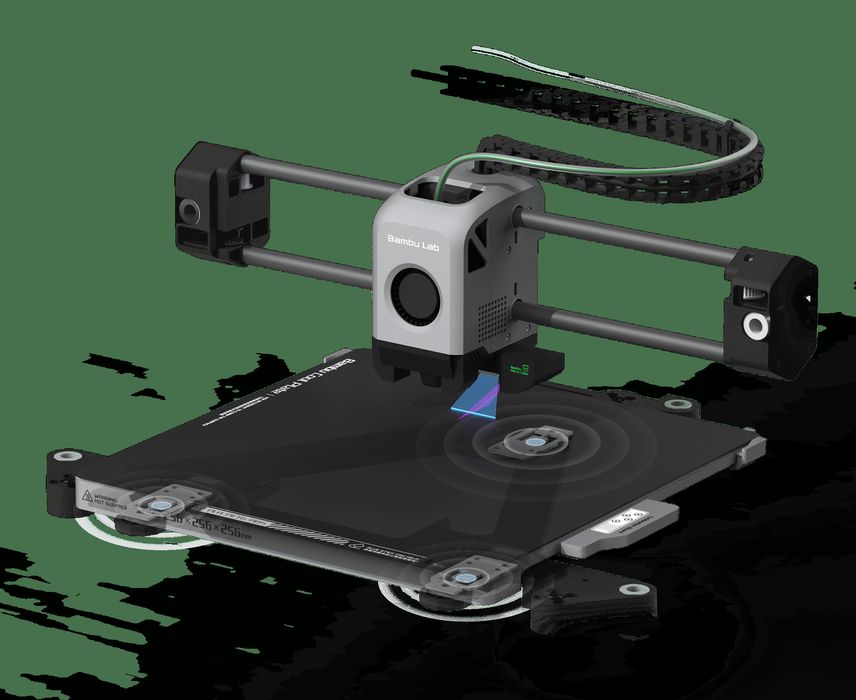

Where do I start? There are so many unusual features on this device! Let’s list the basics first:

- Build volume 256 x 256 x 256

- Fully enclosed

- Activated carbon chamber air filter system

- 1.75mm filament with 0.4mm nozzle diameter

- Flexible steel removable print plate

- Bed heating to 120C, higher than most

- Maximum 500mm/s toolhead speed

- Prints PLA, PETG, TPU, ABS, ASA, PVA, PET, PA, PC and CF filaments on the Carbon version

- Dual toothed gear extrusion

- Onboard webcam

- Door sensor

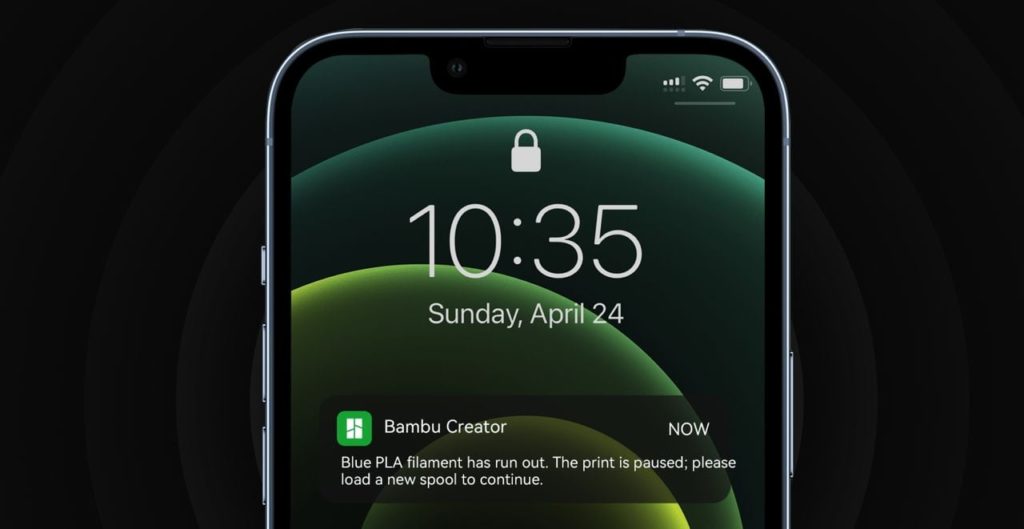

- Filament out sensor and process

- Power loss sensor and process

- 5.5” color touchscreen

- Controller is a Quad ARM A7 @ 1.2GHz

- Software to be used: Ultimaker Cura, PrusaSlicer, SuperSlicer

Then there’s the more advanced features. Again, many of these have never been seen on a desktop 3D printer previously:

- Filament odometer

- 43 realtime sensors

- Native 3MF file format support

- Complete closed loop cooling system controls for all fans

- Print speeds approx 2X normal 3D printers, see explanation below

- Mobile app for full control

- All calibration is completely automated

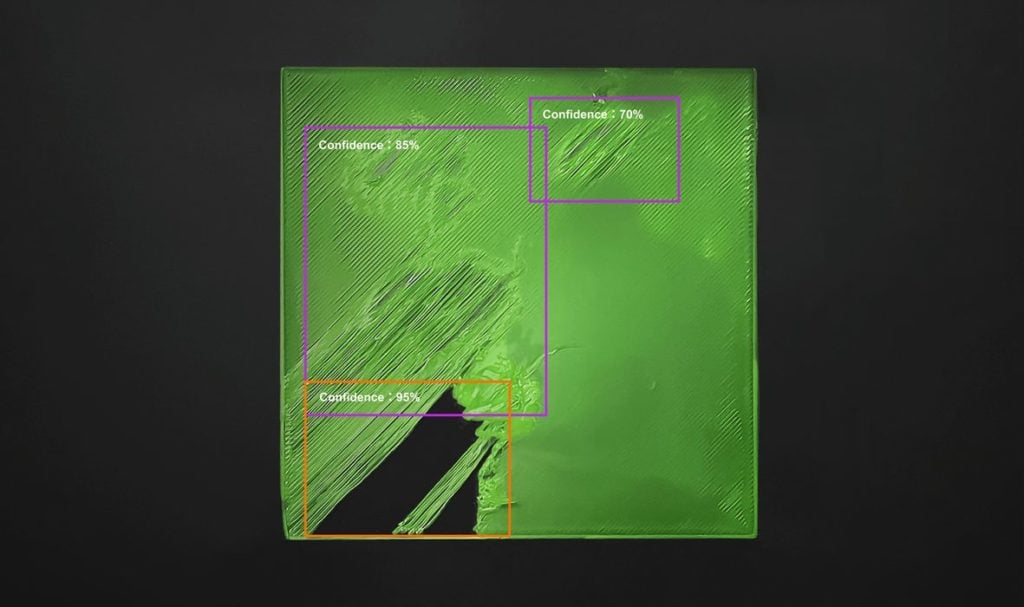

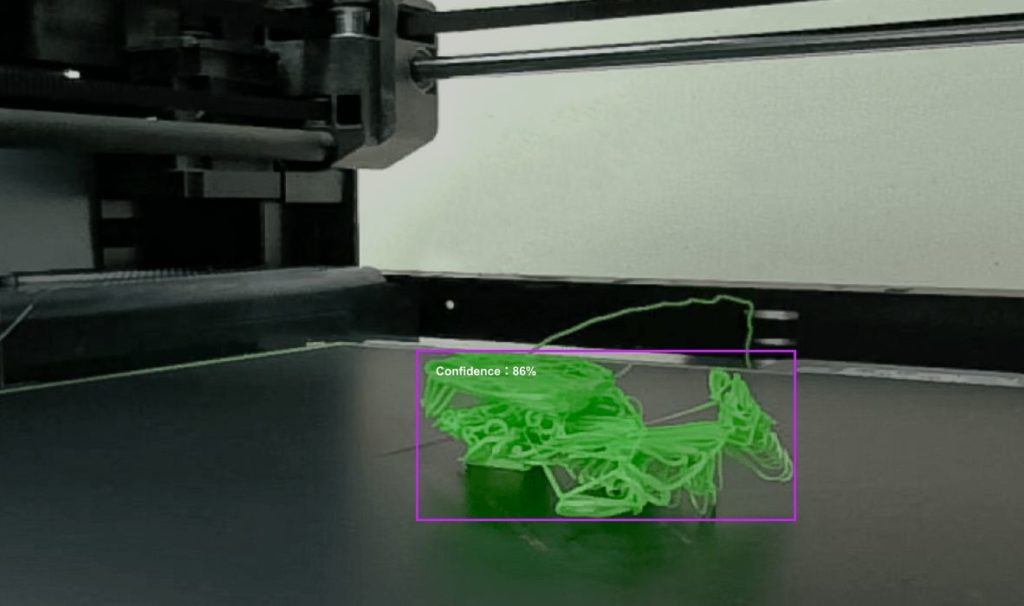

- Real time print failure detection system

- LIDAR sensor

- Ultralightweight carbon rails

- Ceramic hot end heater

- Multiple colors / materials within same job

- Automatic Material System

- Welded steel frame

- RFID-detected spools

- 2TOP capacity NPU (Neural Processing Unit)

The last item, the NPU, deserves special attention beyond all the other amazing features. It’s a Neural Processing Unit that can provide realtime AI capability, and the X1 definitely makes massive use of this feature.

First, it uses the LIDAR sensor to measure the print surface to micrometer accuracy and thus level the bed in a very different and more accurate manner. The Z-gap is also set in this way. I don’t know of any other device that does this.

The AI capability is also used to monitor print progress: filament flow is monitored and corrected automatically through the Automatic Material System (AMS). I don’t know of any other device that does this:

The controller monitors toolhead motion in order to detect vibrations that result in “echoes” in the print. These are actually compensated for in realtime, eliminated this ringing effect. I don’t know of any other device that does this:

The AMS holds four spools, but apparently the X1 is able to provide up to 16 different colors, “4×4”. I’m not sure how this works, as the extruder seems to have only one filament entering. The X1 must be able to switch filaments in mid-print, like some other multimaterial 3D printers.

The AMS is enclosed and can keep hygroscopic materials dry. Spools are identified by RFID chip so that the X1 “knows” exactly what is loaded in the machine. I’m not sure if this implies that you must purchase filament only from Bambu Lab, but we’ll learn more when the device is released.

The X1 boasts of “dedicated support filament” that provides for breakaway supports. I’m also not sure how this works, but I suspect it’s simply a different material that doesn’t bond with the model material.

Due to the AI-controlled motion system and robust hardware, the X1 is able to 3D print quite a bit faster. Bambu Lab said they can print approximately twice as fast as normal 3D printers (which suggests a speed near 120mm/s) and still maintain high quality with a 0.1mm layer size. That’s impressive, and I’d like to see this working in person.

You’re probably wondering what the price of the X1 could be, and so am I. Bambu Lab has not yet officially launched the machine, but they intend on doing so via Kickstarter later this month. My suspicion is that it will be quite a bit more than the inexpensive desktop devices that sell for US$300-700, but less expensive than some professional units that sell for US$5,000-7,000.

We’ll find out soon enough.

Via Bambu Lab