Charles R. Goulding and Preeti Sulibhavi look at how 3D printing can assist in growing desalinization deployments.

Water covers about 71% of the earth’s surface, and 97.5% of it is salt water. That is a lot of undrinkable water, especially when many regions around the globe are experiencing water shortages or even droughts.

California is now experiencing its third year in a row of crippling drought conditions. To combat this water crisis, Poseidon Water, a developer, was looking for approval to build a US$1.4B desalination plant off the shore of Huntington State Beach in California. The plant would have been dedicated to turning seawater into drinking water and was supported by Gov. Gavin Newsom.

However, on May 12, 2022, the California Coastal Commission voted against the facility. The Commission acknowledged that the findings did not indicate that desalination is “unapprovable,” or that the Commission is against the development of new, reliable sources of water in Southern California.

In America, transporting water from aquifers remains the favored method because of the lesser overall costs involved. However, freshwater sources are inadequate to meet the demand. Against all the gloom described above, there is good news. Desalination technology has the potential to be made even more cost-effective than traditional water sources.

The challenge for innovators is to lower the costs of desalination technology, which largely involves steep energy usage in blasting water through filters. In order to meet the challenge, investments in R&D must be increased substantially.

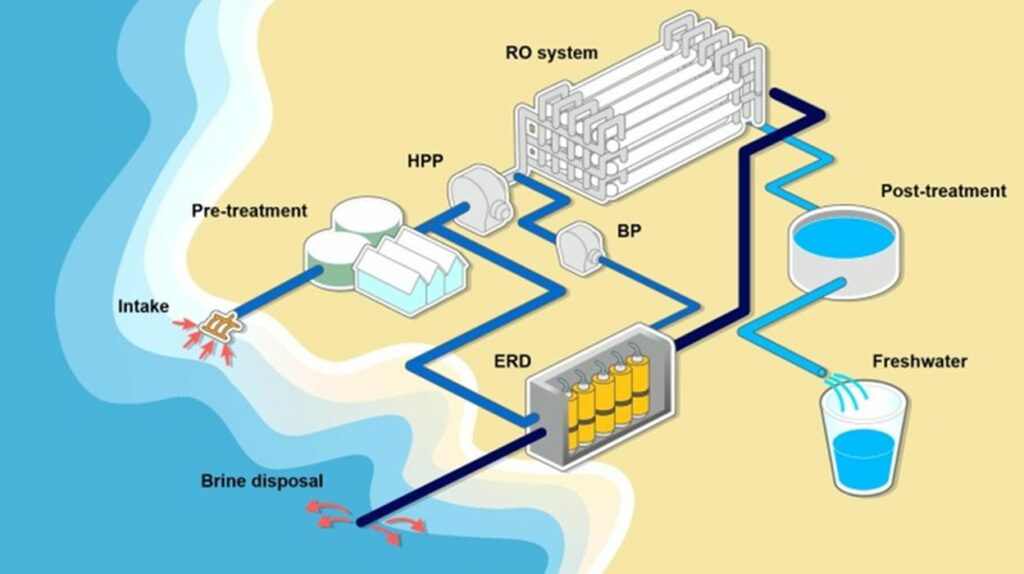

Desalination is a term used to describe the extraction of salt and other minerals from water. The process is useful in producing water suitable for human consumption, irrigation, and many other uses. It is typically utilized on ships and submarines, however, the technology can also be scaled up to provide flowing water for communities and cities as well.

Nonetheless, due to higher energy costs associated with the process, it generally costs significantly more to produce potable water using this method. The preferred course is still transporting from water reservoirs or extracting from the ground. Still, these alternatives are not available in many regions. Thus, desalination is a viable option if construction and operating costs can be reduced.

Israel has proven to be a pioneer in this industry. With the constant growth in population and inconsistent precipitation, demand for natural water resources has risen dramatically. The country has taken measures, since its first desalination plan on August 3, 2000, to increase the supply of drinking water by the desalination of seawater, and brackish water. Today about 585 million cubic meters of water per year are desalinated in Israel.

Water Desalination and 3D Printing

The capability of 3D printing to fabricate complex objects in a fast and cost-effective manner makes it highly desirable over conventional manufacturing processes. Currently, there has been a rapid increase in research using 3D printing for membrane separation, desalination and water purification applications, potentially revolutionizing this field.

Recent advancements in 3D printed materials and methods for water-related applications including developments in module spacers, novel filtration and desalination membranes, adsorbents, water remediation, solar steam generation materials, catalysis, etc. The emergence of new 3D printers with higher printing resolution, better efficiency, faster speed, and wider material applicability has garnered more interest and can potentially reshape research and development in this field. The promising potential, challenges and future prospects of 3D printing, additive manufacturing, and materials for water resource and treatment-related applications

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Water is a basic and essential element for life on this planet. With so many people and so few freshwater sources, desalination, including 3D printing technology, appears to be a viable solution to a problem faced by many both at home and abroad.