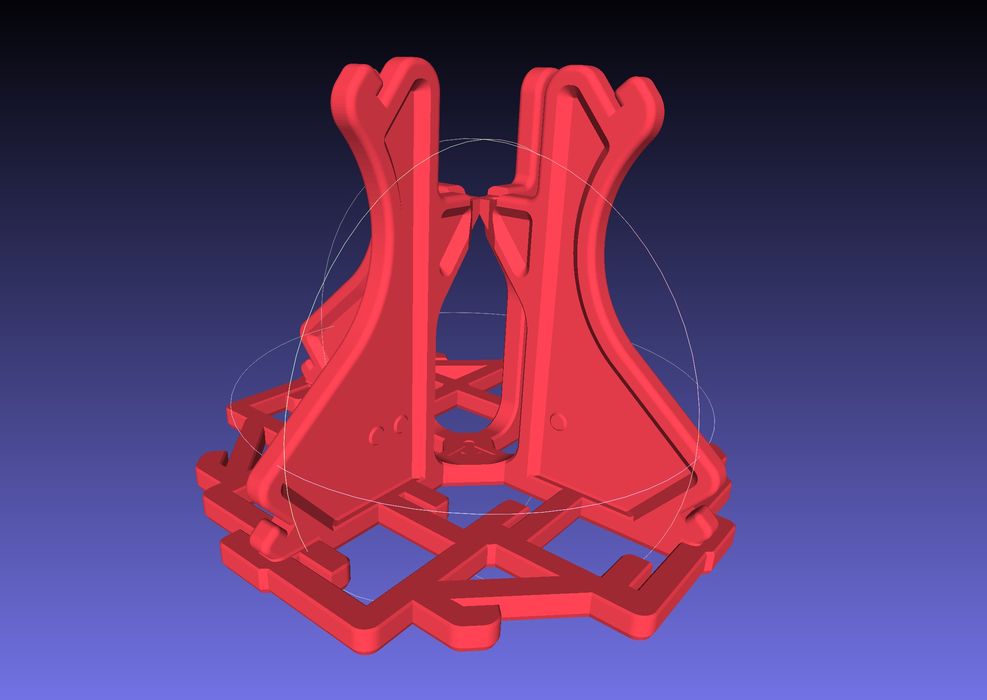

This week’s selection is the Calilantern by Vector 3D.

What the heck is a “Calilantern”? It’s another calibration object used to fine tune 3D printers. But this calibrator is quite unlike most of the typical calibration pieces that focus on surface quality, overhangs and stringing.

Instead, the Calilantern focuses on the alignment of the motion system.

For cartesian-style 3D printers the assumption is that the motion system is perfectly square; each corner should be exactly 90%.

That’s the plan, but the reality is often different. Sometimes it’s not quite visible, but it may be that the motion of the axes does not produce perfectly “square” objects. Imagine a square, and you push one of the corners towards the center slightly. That’s what can happen to a 3D printer.

The result is that printed objects are not “square”. They will be twisted very slightly. For many objects this doesn’t really matter. However, it is critically important if you’re producing mechanical parts that have to fit together, and especially so if there are specific dimensional tolerances required.

The Calilantern is designed to measure all this in a very precise manner.

How does it work? You first print the object in the material and slicing parameters intended for production. Then the Calilantern is measured with a set of calipers.

You’ll notice that the Calilantern’s design includes a number of measurement points along several key angles. These measurements are collected in a spreadsheet provided with the Calilantern, which computes the skew of the motion system. There’s even a 30-page manual to walk you through the process.

This is an incredibly ingenious design that provides a practical method for tuning an often-ignored aspect of 3D printer mechanics.

The Calilantern is provided by Vector 3D, an interesting online shop where a number of unique 3D printing parts and models are offered to the public.

I tried the Calilantern, and it’s an interesting print. Once you’ve printed it, it’s simply a matter of doing 14 measurements (three times each to get a good average), and filling the results in the provided spreadsheet. The spreadsheet then calculates several factors automatically:

Size distortion for X and Y axes

Skew for XY, ZX and ZY axes

Extrusion error for inner and outer perimeters

In my measurements, the results on the printer I tested were far less than one percent, which I guess is pretty good. If they’re sufficiently off, then the spreadsheet actually creates GCODE for both Klipper, RepRap and Marlin firmware that can be inserted into your slicer to correct subsequent prints. It also generates slicing adjustments to flow rates to adjust for sizing. This is extremely helpful!

This 3D model is available for download at a cost of US$13, which is somewhat more than you’d pay for other calibration objects. However, this one provides value you can’t find elsewhere.

Via Vector 3D (Hat tip to Brian)