This week’s selection is Ceramic House by Studio RAP.

What is Studio RAP? According to their site:

“Studio RAP is an architectural design company where we combine the power of computational design with innovative digital fabrication methods. Our team consists of architects, designers, roboticists, programmers and researchers. Together we explore innovative technology and try to improve the way we design, produce, manage and build architecture.”

That sounds a lot like what architectural firms might look like in coming years, but they are here today. One of their most prominent projects recently has been “Ceramic House”.

Ceramic House is a reimagined building facade on a multi-story building in Amsterdam. Whereas neighbouring buildings present mere bricks, Ceramic House now sports a complex array of 3D printed surfaces, all generated using computational techniques.

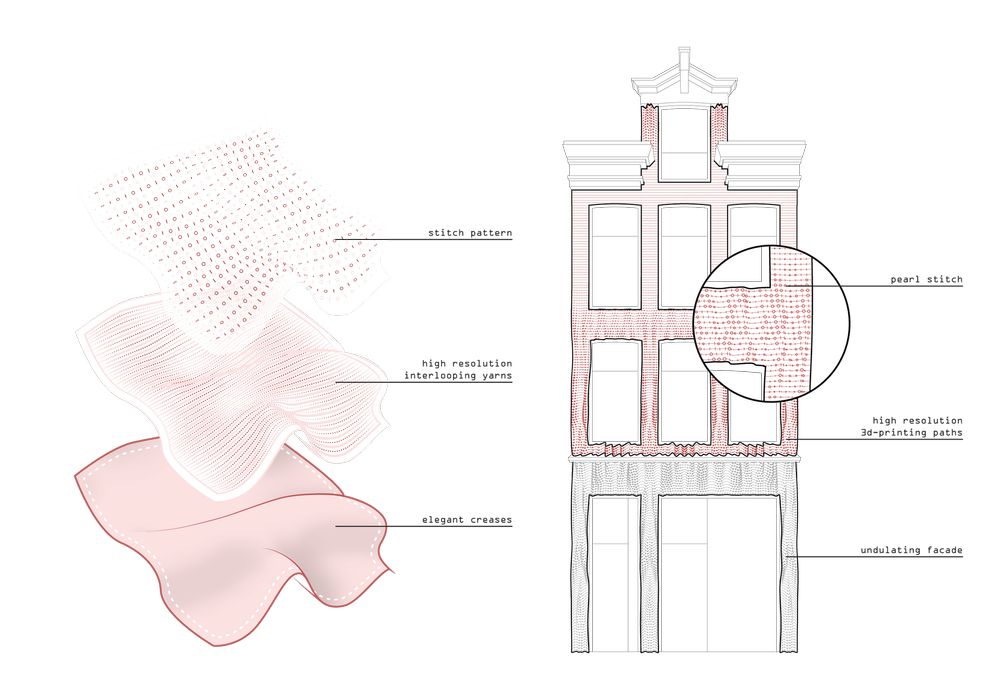

The facade has two “layers” corresponding to the different levels of the building. The surfaces include “stitch patterns”, “high resolution interloping yarns” and “elegant creases”. Studio RAP explains the design concept:

“Studio RAP has replicated the silhouette of the original facade, continuing the characteristic tripartite structure of the street and maintaining the overall character of the site. The scale, size, type, and color of the ornaments and materials are all carefully synced with the neighbouring buildings to allow a seamless integration of traditional and contemporary architecture.”

While Studio RAP used robotic 3D print technology to produce the surfaces, this was done offsite. They operated the 3D printer at a central location where smaller components were produced.

These were shipped to the build site, and then mounted with custom-cut metal shelving, shown here. This provided a strong means to attach the 3D printed components to the structure.

I’m hoping there are more projects of this type in the future, don’t you?

Via Studio RAP (Hat tip to Tuan)