This week’s selection is the electronics-free robot gripper by researchers at the University of California San Diego.

End effectors are the business end of robotic arms. These items implement some type of functionality, be it extrusion, touch sensing, drilling or other application. One application is grasping objects so that they can be moved around by the robot. For this purpose, one needs a “gripper”.

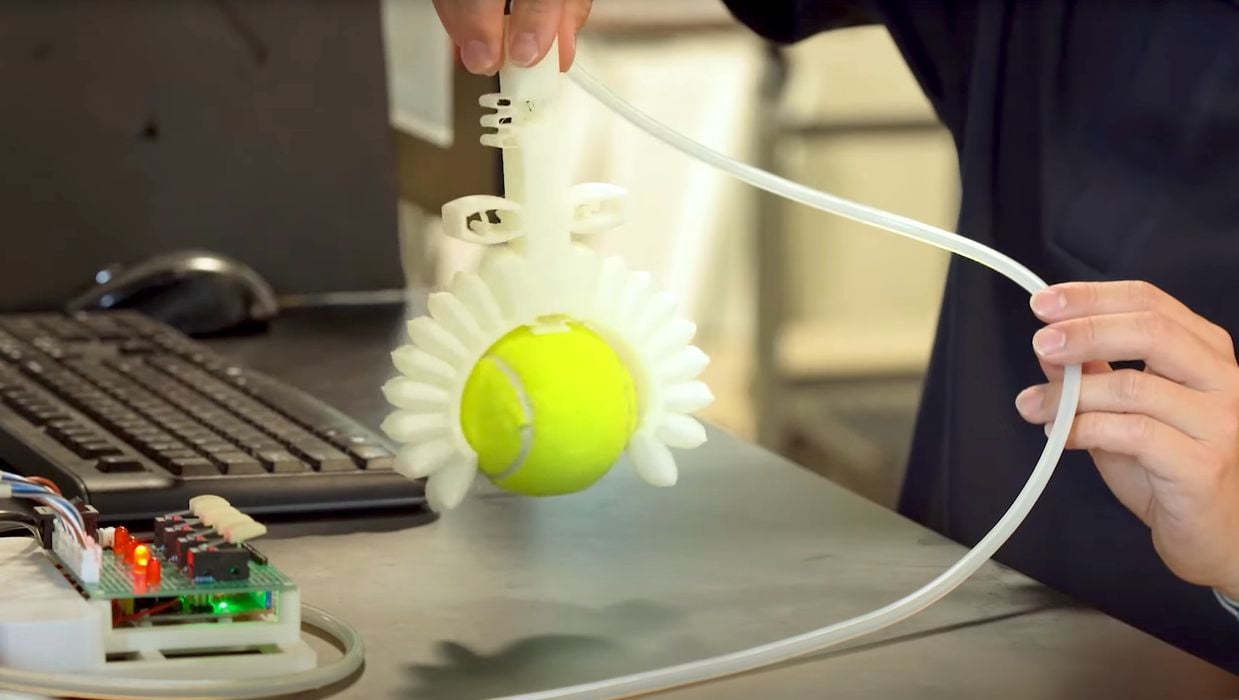

UCSD researchers designed a 3D printable a robot gripper, but with a difference: it requires no electronics and can be directly used after printing.

A gripper is a mechanical device — it moves to grasp the object — so how can you do so without electronics or sensors?

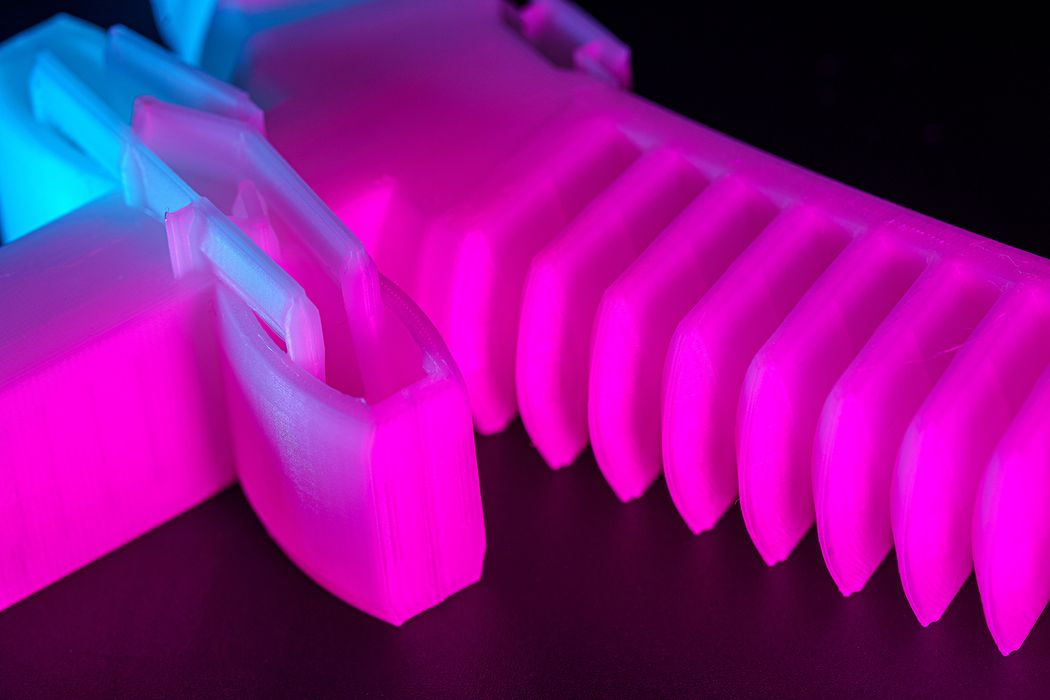

Their approach was ingenious. As you can see in this video, the gripper is printed in a flexible material. The design includes a way to hold pressurized air, which powers the gripper.

As the gripper approaches the object, a mechanical sensor is triggered when touch occurs. This causes air to shift internally in the gripper, and it closes over the object. A similar approach is used to release the object.

The benefit of this design is that it is immediately useful: print and use. That’s not the case for many robotic aids, and I’m wondering if this approach will inspire others to design similarly “immediate use” designs.

While this design was intended for robotics, there is a lesson here: whenever possible, design 3D prints to be ready to use when printing completes. Let’s take out as much work as possible and make things even more efficient!

Via UCSD