This week’s selection is the prototype Soy Sauce Lid by Matthew Clark of Odachi Design.

Odachi Design and Clark are based in Los Angeles, and have been creating unusual product designs for some years. One of Clark’s designs was featured on Fabbaloo in 2015, the Innervision Bicycle. Clark explained to us that this project didn’t quite make it to production, but he’s far more confident with his latest creation: a “smart” soy sauce lid.

I know what you’re thinking: why does a soy sauce container lid require so much attention? Isn’t it just a plastic cap with a threaded inner edge?

No, that’s not it at all. Clark explains the problem:

“Soy sauce’s greatest enemy is oxygen. So, with my design, I harnessed the capabilities of 3D printing to integrate a gravity valve within the lid itself. This is achievable with 3D printing, but costly or much more difficult otherwise. The valve is printed within the top when it’s produced. This was created to effectively maintain the flavor and shelf-life. After every pour, the remaining liquid aids the seal.”

Now you know: when soy sauce is exposed to the air, it degenerates. You may have already realized this because soy sauce tends to get a bit darker after you open the bottle. Apparently this is quite a topic at Kikkoman, the ubiquitous makers of soy sauce found everywhere.

Clark wanted to be “plug compatible” with the original Kikkoman lid and retain the overall design, and as you can see in the image at top comparing the new smart lid with a normal Kikkoman bottle, they appear about the same.

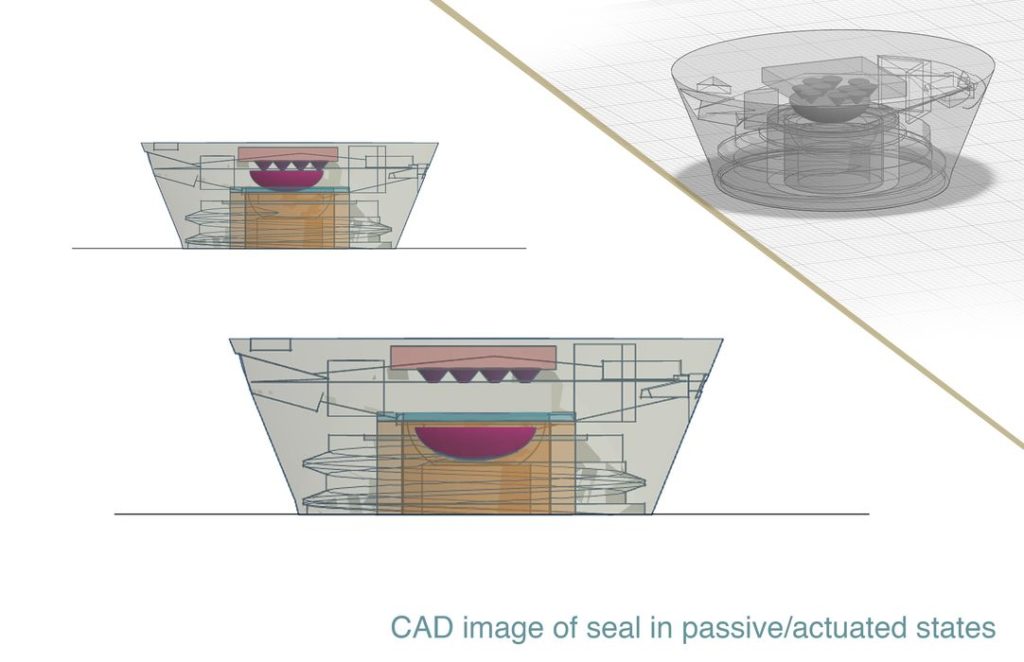

While the lid appears straightforward on the surface, the inside is where all the action occurs. This diagram shows the mechanics taking place on the lid’s interior.

Clark is satisfied with the design:

“It was a challenge to put my touch on such an iconic piece, but my aim was to honor the original by enhancing it for the 21st century. It was also a great opportunity to demonstrate the solutions 3D manufacturing can provide with environmentally-conscious materials.”

The next step for Clark and Odachi Design is to move this prototype into production, as it will have to be made in a food safe manner.

However, Odachi Design may face troubles if Kikkoman enforces legal restrictions on their design, as Honda have recently done to other 3D designers.

Via Odachi Design