Filament drying is becoming an essential step in 3D printing, and here’s a way to do so economically.

Drying filament is essential because many of today’s engineering materials — and even PLA — can absorb moisture from the air. This embedded water boils out during extrusion through the FFF 3D printer’s hot end, causing bubbles. These bubbles — which can sometimes be audibly heard during printing — mess up the surface quality and degrade the part’s strength, sometimes significantly.

You really want dry filament.

You could just put your spools in the oven, but then you’d risk melting and distorting the filament because ovens have terrible temperature control.

There are plenty of filament dryers on the market that can do this for you. Some are passive, using a pile of desiccant to absorb the moisture, while others employ active heating to expunge the humidity. More advanced dryers use vacuum technology, or even “dry on demand”.

But for most DIY 3D printer operators, there is a far less expensive option: a food dryer.

These are commonly available in hardware stores, and are designed for drying garden produce. They’re typically available for US$20-40 each, and work pretty well.

There’s one problem with them, however: they aren’t that big. Usually you can squeeze in one or perhaps two spools of filament.

Now there’s an answer. At our lab, technician Jeff Stobbe had an idea to make a “stretch” version of the food dryer to hold more spools.

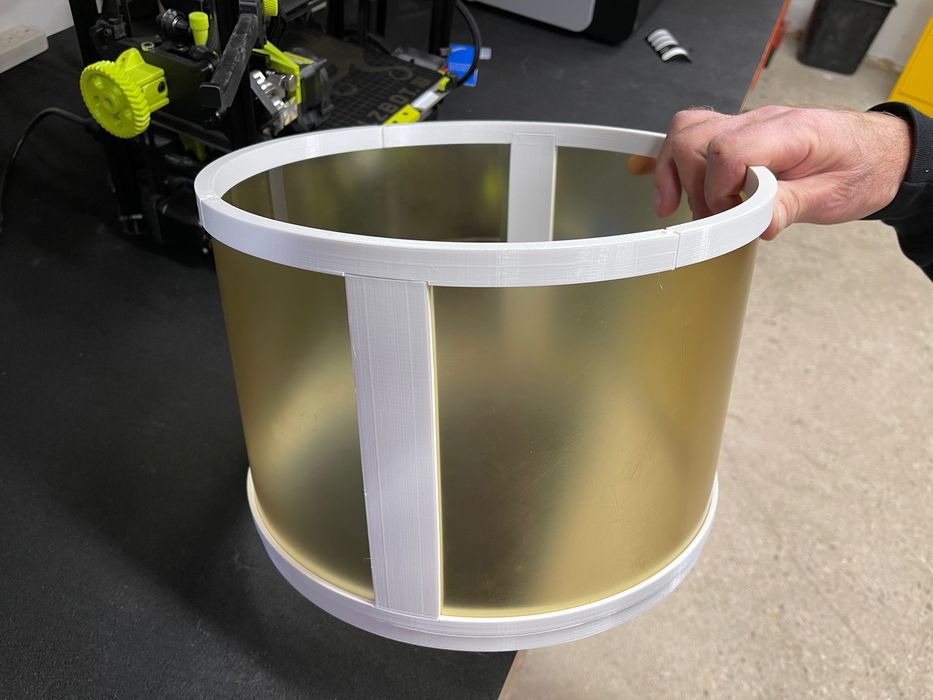

Stobbe leveraged some leftover print sheets from a Fortus 3D printer (these are made from ULTEM) and fashioned a holder for them.

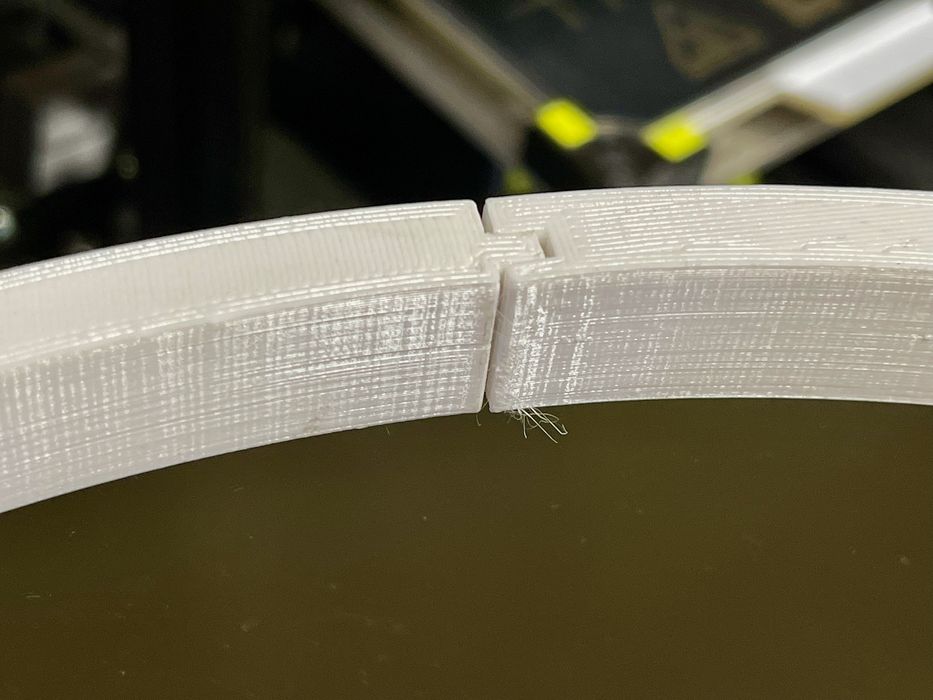

The holder was a bit big to print in a single piece, so it was segmented and then assembled together with the sheets.

The holder was designed to match the existing dryer lid, so it simply goes on top of the stretched volume.

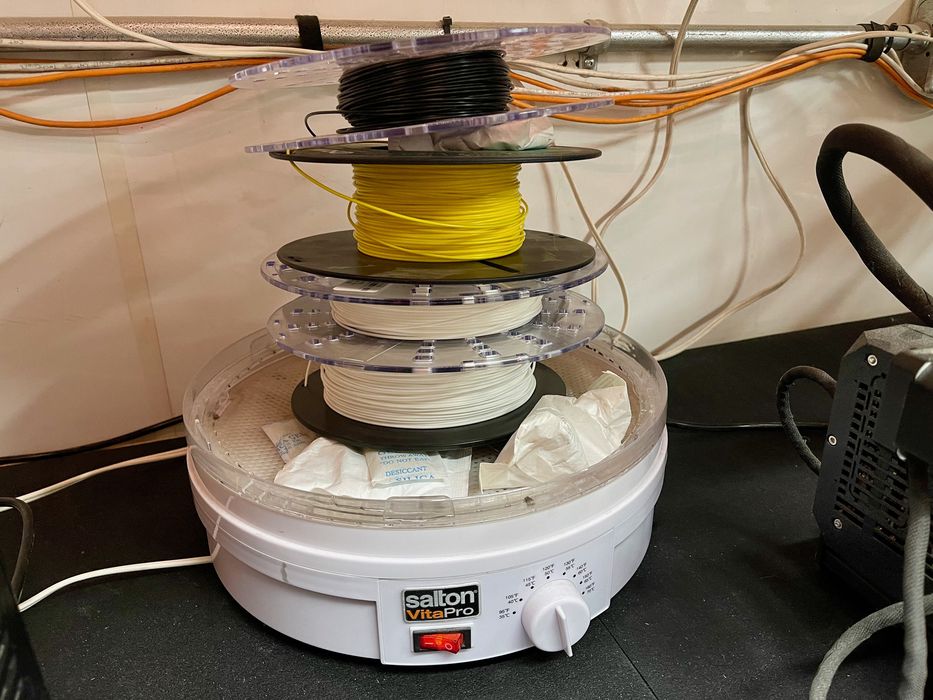

Inside there’s much more space to accommodate several spools, as you can see here. Unfortunately this design doesn’t allow for printing directly from the dryer, but that could be possible if a rotational component was added in a future version.

Nevertheless, there is now plenty of room for several spools of engineering material in the new stretch filament dryer.

When you have a 3D printer, CAD software and some imagination, almost any problem can be solved.

My cylindrical food dryer from Amazonhas a rotating base. Isn’t that the rotating component? It would be easy to hack to get the right speed.