Charles R. Goulding and Preeti Sulibhavi look at several 3D printed innovations at the University of Maine.

In November 2022, the University of Maine Advanced Structures and Composites Center (ASCC) showcased the first 3D printed house made of bio-based materials, called BioHome3D.

The 600-square-foot prototype features 3D printed floors, walls and roof of wood fibers and bio-resins. The house is fully recyclable and highly insulated with 100% wood insulation and customizable R-values. Construction waste was nearly eliminated due to the precision of the printing process.

“Our state is facing the perfect storm of a housing crisis and labor shortage, but the University of Maine is stepping up once again to show that we can address these serious challenges with trademark Maine ingenuity,” said Gov Janet Mills.

“With its innovative BioHome3D, UMaine’s Advanced Structures and Composites Center is thinking creatively about how we can tackle our housing shortage, strengthen our forest products industry, and deliver people a safe place to live so they can contribute to our economy.

The project was undertaken as a collaboration between Oak Ridge National Laboratory and the University of Maine (UMaine).

Oak Ridge National Laboratory’s (ORNL) Manufacturing Demonstration Facility, a leader in advanced manufacturing, and UMaine, home to ASCC, Forest Bioproducts Research Institute and School of Forest Resources, are natural partners in the field of large-scale, bio-based 3D printing. The Maine Technology Institute supported the design of the prototype, and MaineHousing was a key partner in developing and reviewing the specifications for the home in alignment with low-income housing standards.

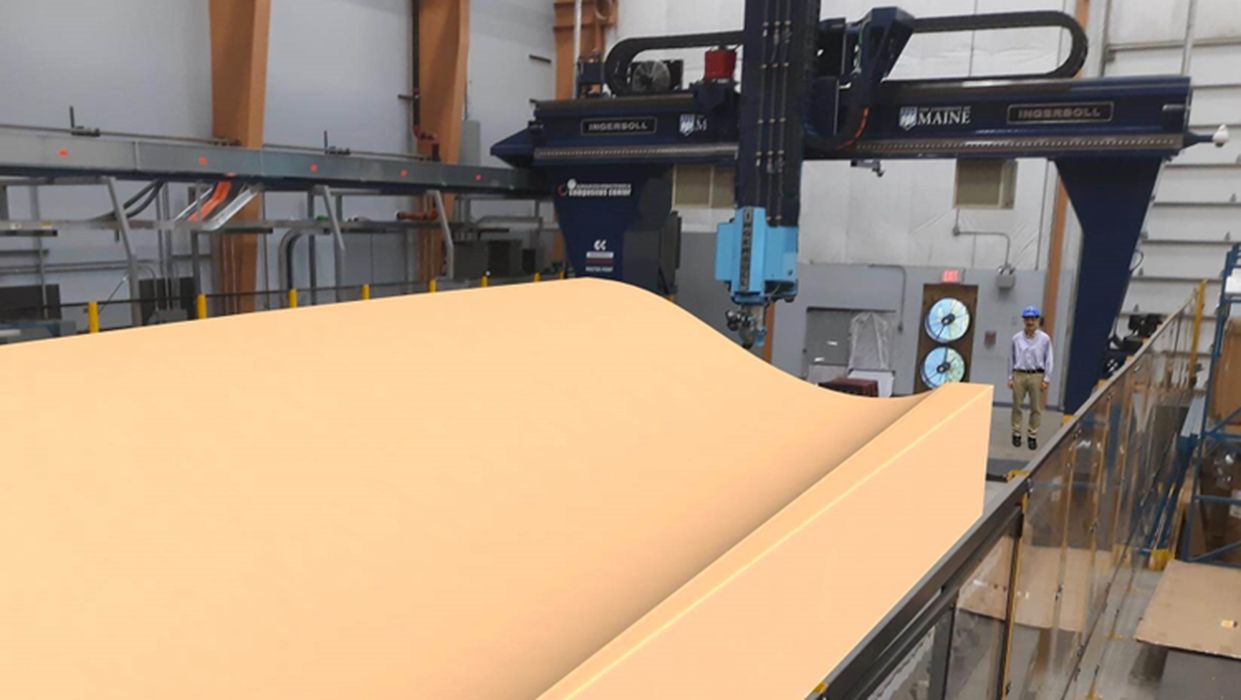

In 2021, news came of UMaine’s large, segmented, 3D printed wind blade molds for wind turbines. In this instance, UMaine partnered with ORNL to apply carbon fiber technology, materials science and 3D printing in wind energy applications. As a result of the successful use of 3D printing, TPI Composites and Siemens Gamesa (SGRE) began partnering with the UMaine Composites Center on the project to use this successful solution and bring it into practice. Ingersoll Machine Tools, the 3D printer manufacturer, and Techmer PM, the cellulosic-thermoplastic feedstock compounder, also are on the team, providing the ability to scale-up both equipment and feedstock production.

UMaine has other accomplishments to speak of. In 2019, the world’s largest prototype polymer 3D printer, the largest solid 3D printed object and the largest 3D printed boat was unveiled and entered into the Guinness World Records.

The massive 3D printer was designed to print objects as long as 100 feet by 22 feet wide by 10 feet high and prints at 500 pounds per hour. The unique printer supports several ambitious initiatives, including the development of biobased feedstocks using cellulose derived from wood resources, and rapid prototyping of civilian, defense, and infrastructure applications.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

UMaine’s accomplishments are impressive. UMaine has applied 3D printing to solve some of our most common and pervasive societal problems such as marine transportation, housing, alternative energy and infrastructure. We look forward to seeing more achievements by this institution.