Desktop Metal has announced that 4140 low-alloy steel is now qualified for high-volume use on the Production System platform.

The company, which six months ago expanded its Single Pass Jetting-driven Production System into a production lineup, has been increasing its materials library to offer more in metal 3D printing.

Qualified Metals for Additive Manufacturing

Materials in the DM library for the Production System platform fall into three categories, which they describe as:

- DM Qualified: Printing and sintering profiles developed by Desktop Metal for the Production System, with fully characterized material and mechanical properties.

- Customer Qualified: Printing and sintering profiles developed in partnership with customers and/or partners for the Production System, with material and mechanical properties suitable for customer/partner applications.

- Active R&D: Initial testing completed by Desktop Metal demonstrating binder and process compatibility. Printing and sintering profiles under final development.

The newest material to fall into category #1 is the ever-popular 4140 steel. The announcement explains:

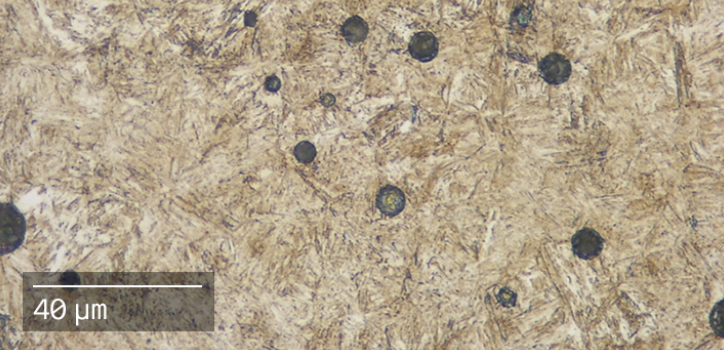

“Desktop Metal’s materials science team has validated that 4140 low-alloy steel printed on Production System technology and sintered by Desktop Metal meets MPIF 35 standards for structural powder metallurgy parts set by the Metal Powder Industries Federation.”

That MPIF standard is itself a serious matter, as that organization says:

“The Metal Powder Industries Federation issues standards to provide the design and materials engineer with the information necessary for specifying powder metallurgy materials which have been developed by the powder metallurgy and metal injection molding parts, powder, and equipment producers. MPIF standards are intended to present and clarify powder metallurgy technology so as to aid in the conduct of business. PM materials specifications and test standards relate to those activities that concern designers and users of PM parts as well as the manufacturer.”

For 3D printing materials to fall under those rigorous standards offers a much-needed level of quality assurance for additive manufacturing.

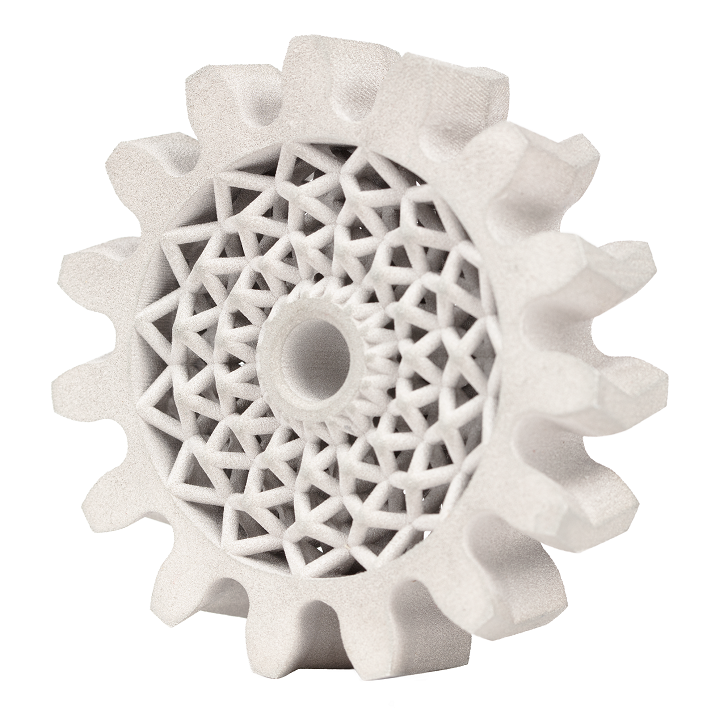

Low-alloy steels like 4140 are popular for their use across many common applications; 4140 in particular is well known for being a tough material with high tensile strength and good resistance to abrasion and impacts. Applications are often found in automotive, oil and gas, and industrial operations for such mechanical parts as gears, downhole components, couplings, spindles, and nuts and bolts.

As more common metals make their way into additive manufacturing, companies like Desktop Metal are ensuring that those familiar materials perform to the same quality standards as they do in other production processes. Today’s announcement also says:

“Desktop Metal is the first and only company to qualify 4140 low-alloy steel for use with metal binder jetting systems, enabling its use in mass production end-use part applications.”

Co-Founder and CTO Jonah Myerberg notes of the work that went into the new qualification:

“4140 has been a challenging material for metal binder jetting because of its low alloyed content, tight carbon control requirements, and low ignition energy, which together require advanced binder chemistry,as well as extensive printing and sintering optimization and atmospheric controls for safe processing.”

Production System Materials

Revisiting the Production System platform materials library, Desktop Metal now offers:

- DM Qualified:

- 17-4 PH Stainless Steel

- 316L Stainless Steel

- 4140 Low-Alloy Steel

- Customer Qualified:

- Au (Gold)

- Ag (Silver)

- Active R&D:

- Alloy 625 — nickel-chromium superalloy

- 420 stainless steel

- S7 — shock-resisting air hardened tool steel

- H13 tool steel

- Cu (Copper)

- WC-Co (Tungsten Carbide Cobalt) — often called cemented carbide

As more materials are qualified, binder jetting at the production level — that is, high-volume, actual production — is moving forward from the realm of “that’s promising” to a much cleaner “that’s possible.”

Via Desktop Metal