Digital Metal announced an accessory for their popular DM P2500 high-resolution metal 3D printer.

If you’re not familiar with Digital Metal, they are a Swedish company that produces the DM P2500 device. It’s a binder jet metal 3D printer, but with an ability to 3D print extraordinarily high-resolution objects, far higher than any other metal 3D printing process.

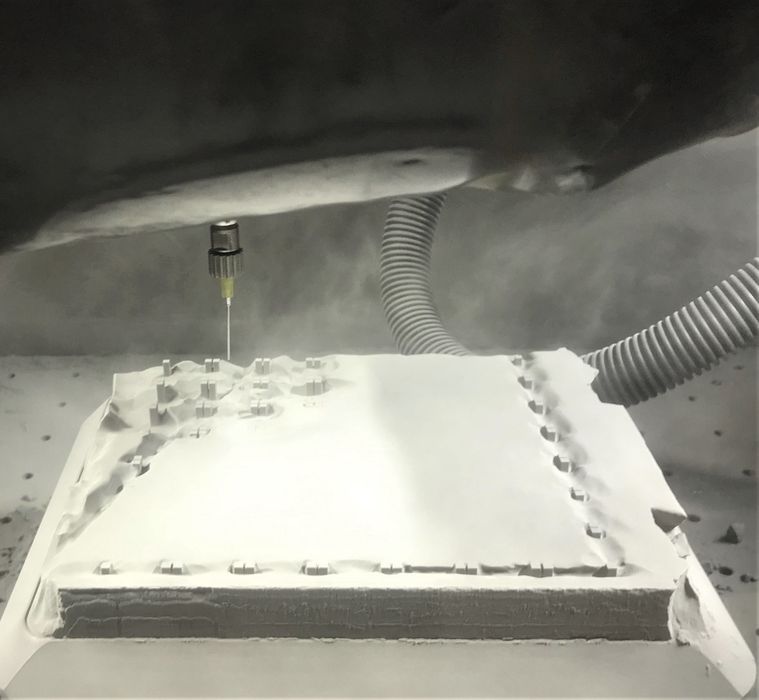

The binder jetting process involves putting down layers of very fine metal powder, then selectively depositing tiny droplets of binder on top. Layer after layer, this gradually builds up a green object.

When printing completes, the green object must be very carefully removed from the loose powder. All stray particles must be taken away from the surface of the print, which then undergoes a sintering process to fuse the metal powder together.

It’s the de-powdering process that is the goal of the new DPS 1000. This device is able to accept a full build plate from the DM P2500 and precisely remove all loose particles in an automated fashion.

Previously this would have often been done manually with an operator wielding an air gun. That process works, but presents the risk of damaging the very fragile green prints. If, for example, the air gun struck the tip of a part it could dent or even break the green part.

This is no longer a risk if the DPS 1000 is used. The device includes a needle-like air blower that roams along the geometry of the printed parts, never touching them.

The best part is the automation. Because the DPS 1000 operates on its own after being loaded and started, that should free up some manual effort to be used elsewhere in the manufacturing process and thus lower the unit cost of any parts produced with the DM P2500.

While the DM P2500 is not an extraordinarily large metal 3D printer, it is often used for higher-volume production. That’s because its very high resolution allows 3D printing of detailed smaller parts, and the device’s build chamber can hold many of them despite its relatively smaller volume.

Digital Metals’s Sales and Marketing Manager, Alexander Sakratidis, said:

“A key benefit of the DPS 1000 for Digital Metal customers is that it will free up time, and also bring consistency by removing the human factor from the equation.”

Digital Metal said they’ve already sold one unit to Fraunhofer IAPT, an operator of DM P2500 equipment.

It’s likely that Digital Metal will sell DPS 1000s to many of their current client base, and frequently bundle them in with new 3D printer purchases.

Via Digital Metal