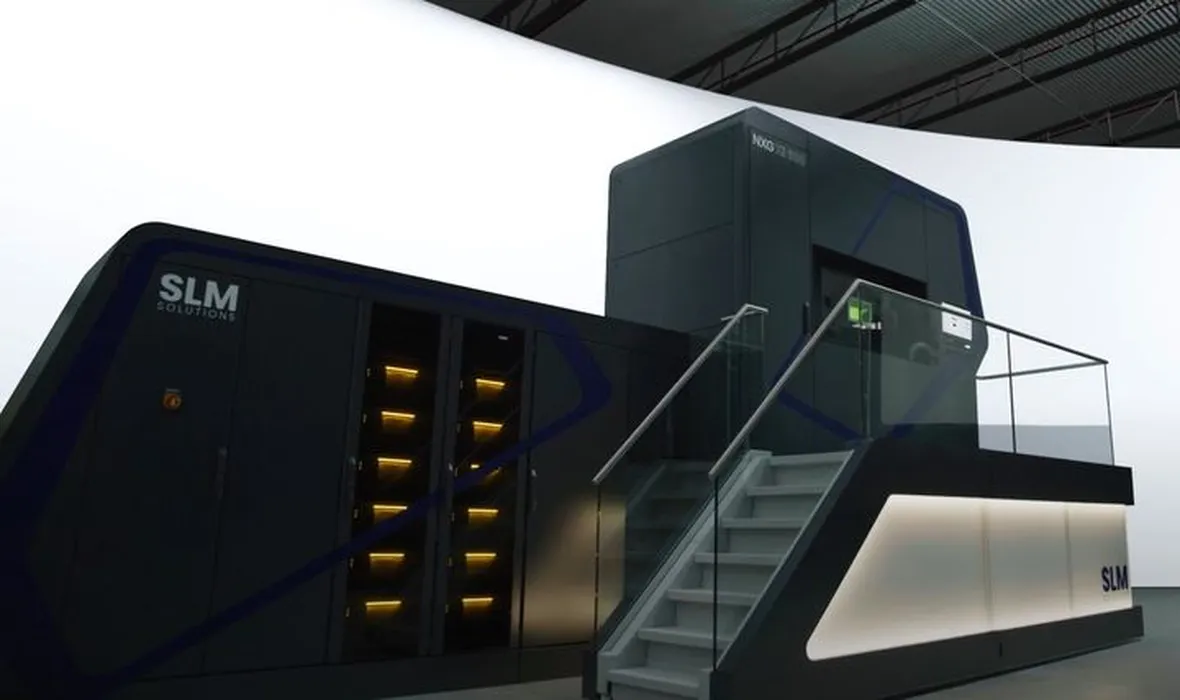

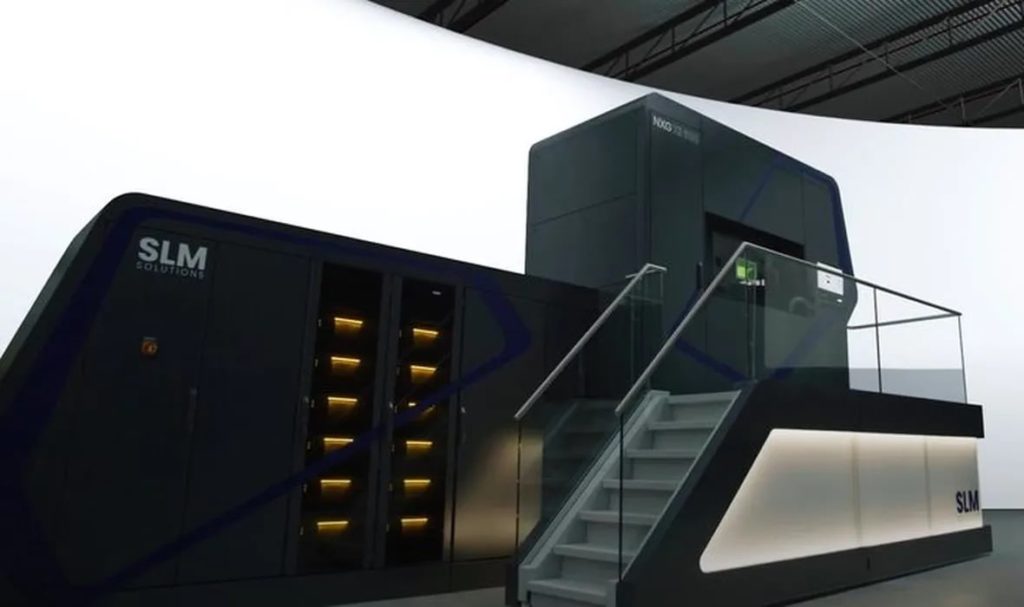

SLM Solutions announced a blockbuster sale of their flagship NXG XII 600 to Divergent, and there are implications.

If you’re not familiar with the absolutely huge SLM NXG XII 600, we have a detailed overview of its revolutionary metal 3D printing technology and its first shipments.

This machine is the largest LPBF device on the market, with a massive build volume of 600 x 600 x 600 mm. Some highlights of this device:

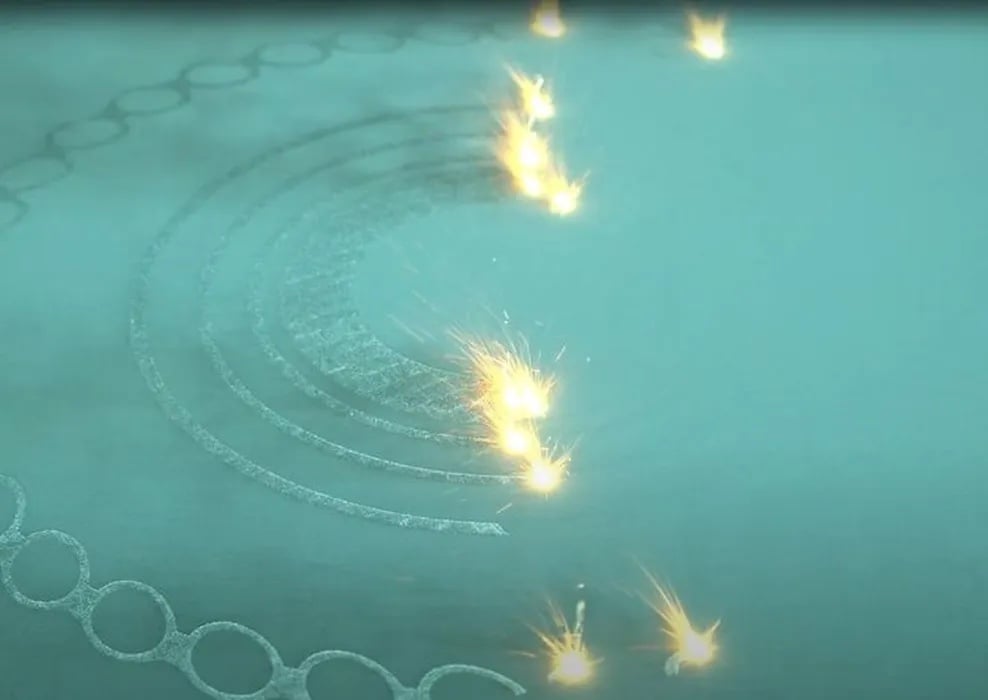

- Equipped with twelve (TWELVE!) 1kW lasers

- Coordinated simultaneous laser activity for rapid speed

- Able to 3D print up to 10,000kg of metal material per year

- Up to 20X faster than typical LPBF equipment

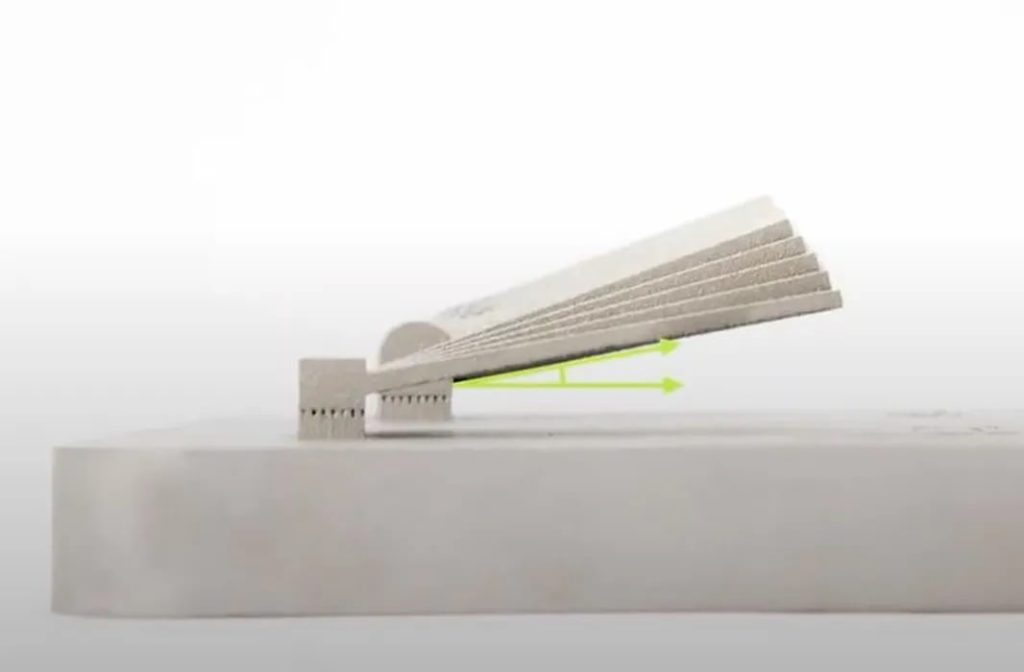

- Advanced recoating system enables production of near-horizontal support-free structures

- Lower post-processing effort required

- Advanced cooling to counteract the 12kW of power landing in the build chamber

- Zoom feature to dynamically adjust laser dot diameter

As you can see, this is a pretty amazing machine. It’s ideal for production due to the large build volume and very rapid 3D print speed.

That’s precisely what it’s being used for at Divergent Technologies. They are a California-based service that produces automotive parts. They’ve been using SLM Solutions equipment for several years, having developed their own in-house production process they call “Divergent Adaptive Production System”, or “DAPS”. Their goal is to provide “lightweighted” parts for automobile production.

Unsurprisingly, they have been using three SLM NXG XII 600s during the beta test period. Evidently they liked what they saw, as they have now purchased another THREE units. In addition, they also operate seven SLM 500s, three SLM 280s and one SLM 125.

That’s a staggering amount of metal production capacity, particularly with the enormous fleet of SLM NXG XII 600’s.

Let’s look at their SLM NXG XII 600s from a fleet perspective:

- Able to 3D print 60 tonnes of parts per year, or five tonnes per month

- Consumes up to 72kW of power when all running

- 600kg+ powder required to fully load each machine

- Potentially US$1M to load all six machines with powder

This is about as serious a metal 3D printing operation as one could imagine.

But why go to all this expense?

This is what I’ve been pondering, and it appears that Divergent Technologies clearly has identified a market for lightweighted metal parts in the automotive industry. Their piloting of the technology no doubt has shown market demand, and now they are scaling up.

SLM Solutions said:

“Divergent’s initial factory deployment will involve the production of thousands of tons of complex, automatically assembled structures, which will be hitting the road over the next two years. This will be followed by the scale-up of its advanced facilities, specially designed for sustainable production using DAPS, including ‘fab-less’ vehicle manufacturing, which will begin with the fully homologated Czinger Vehicles 21C hypercar.”

We don’t know who their other clients might be, but there are apparently a sufficient number of orders to justify these machines and all their associated costs.

By the way, the SLM NXG XII 600 is rumored to “start” at US$600K, suggesting that the purchase is a multi-million dollar venture. It’s actually even more than that when you include the costs of facility, labor, software, materials, post processing, etc.

In years past we saw the blossoming of metal 3D printing in the aerospace industry, after years of experimentation. Today 3D printed parts are routinely used on many new aircraft, and it’s become a standard, at least for certain types of parts.

With this news from Divergent Technologies and SLM Solutions, it may be that a similar breakthrough has taken place in the automotive industry. A company scaling up production capacity to this degree certainly tells us something deep about how the automotive industry is shifting.

Finally, as large as this purchase appears, it may not be the last. If Divergent Technologies succeeds when this equipment is delivered early next year, they may find themselves with additional orders from even more clients. That could mean further expansion and additional huge units from SLM Solutions.

Via SLM Solutions and Divergent Technologies