EOS released information about a rather unusual basketball they and partners were able to 3D print.

The “3D Airless Prototype Basketball” was a prototype produced by the team of Wilson Sporting Goods, General Lattice, DyeMansion and EOS.

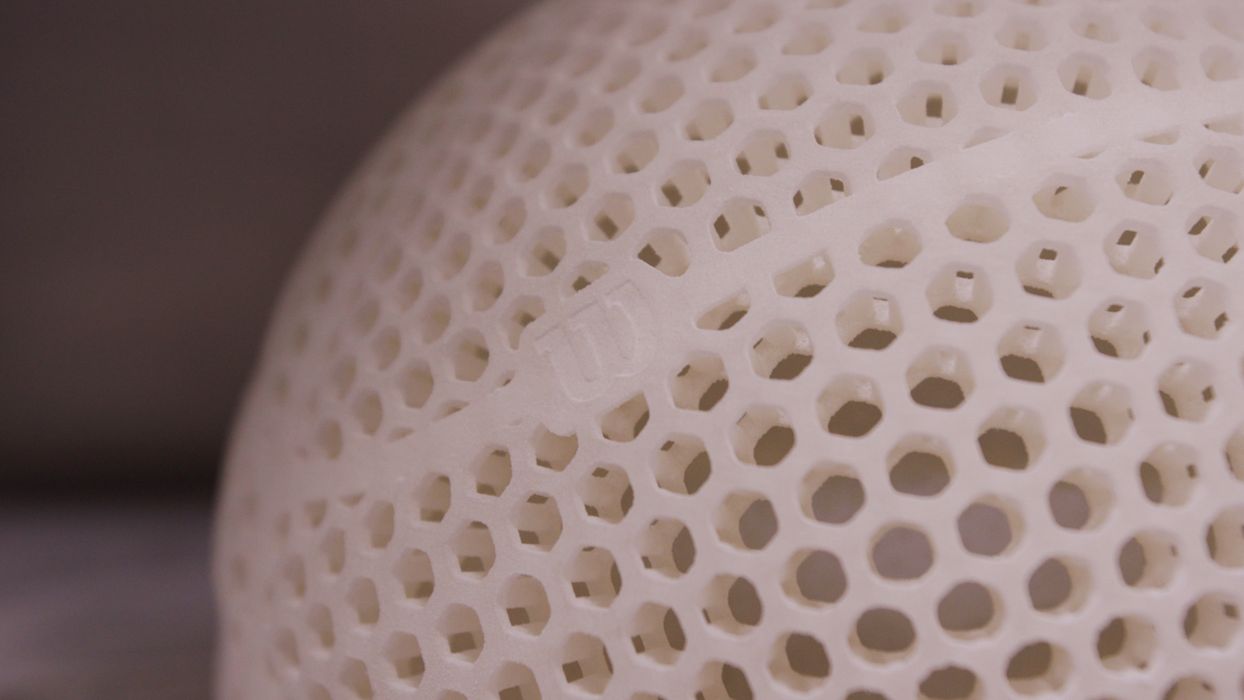

It’s a basketball, but one you’ve probably never imagined: it is airless and composed solely of a lattice comprising the outer shell. It requires no inflation, and indeed it’s literally full of holes so that’s not even possible.

The project was undertaken as an exploration of a new form of product by Wilson, which has singular expertise on the topic: they are the official supplier of balls to the NBA.

Wilson’s Dr. Nadine Lippa and team developed the design of the ball, which is basically a spherical lattice. The team used the services of General Lattice to digitally generate the highly complex 3D model, and then it was printed in an unspecified material by EOS. I would not be surprised if the material was not one of the standard options.

After printing, the ball was colored by DyeMansion, makers of production 3D print coloring systems. For this project, the team chose a very dark black for the ball, perhaps to distinguish it from the typical orange of most basketballs.

Only one ball was produced, as this is a combination of experiment and publicity maneuver. However, I do believe that Wilson genuinely wishes to explore the possibility of eventually making this a real product that everyone can purchase.

Fabbaloo readers may be thinking that a project to make a spherical lattice of basketball size couldn’t be that difficult. I’m thinking I could even design a 3D model of that style. However, there is much, much more to the story.

Such a ball would not only have to assume the shape of the ball, but also its other properties: bounce, weight, handling, durability and more.

Making a design that accomplishes all that is quite a challenge. You can see in the above image that the design seems to include two distinct layers of lattice, which likely assists with the feel of the ball. It turns out that Wilson even has their own “NBA test facility” where balls are rigorously tested to ensure they meet the company’s basketball standards.

It’s not exactly clear how the design works, and all the material provided to us notably excludes any detailed exposure to the design. More than likely Wilson is keeping this a secret due to future product possibilities.

This is a very important project, even though it involves only a single basketball. Its importance is that if successful, it could provide a solid demonstration of additive technology being used in a completely new area.

There are plenty of inflatable objects we use in life, and it may be that many of them could use the same lattice treatment. If so, then we could see a big rise in 3D printer sales because that’s the only kind of machine that can produce these designs.

It may be time to sell your stock in air pump companies.