My proposal to allow 3D print slicers to emboss recycling stamps has generated some interesting ideas.

The story from the other week was entitled, “Making 3D Print Recycling Easier: A Proposal for Slicing Software Developers”.

The gist of the story was that the most commonly used 3D print slicers should all include a feature to emboss or embed the standard recycling symbols on 3D prints. This would allow local recycling operations to quickly identify 3D prints for sorting. Without any symbol, plastic is considered not recyclable — even if it is.

If we all placed the recycling symbols on our prints then we could make a very small dent in the global microplastic problem.

Making such a change would be relatively straightforward, and if done in open source form might quickly find its way into several popular slicing tools.

But there’s just one question: what are the recycling symbols?

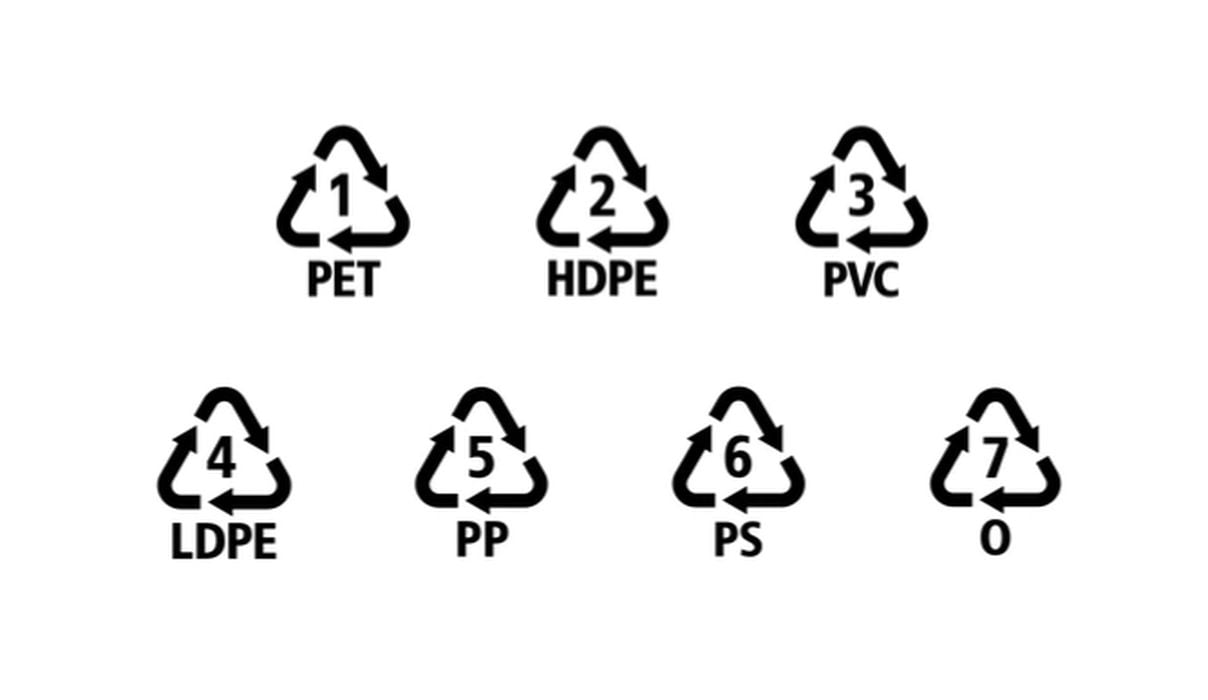

In the original story I proposed using the standard seven material symbols, shown here. The material classifications include:

- PET

- HDPE

- PVC

- LDPE

- PP

- PS

- Other

You’ll note the obvious lack of several commonly used 3D print materials, such as PLA, ABS, ASA, PETG, PCTG, PC, TPU, etc. These would all fall into “other”, and the likelihood of them being recycled drops precipitously.

A suggestion arrived from Dr. Joshua Pearce, who works in the research area of sustainable 3D printing. He pointed out a research paper he and team worked on way back in 2015, entitled, “Polymer Recycling Codes for Distributed Manufacturing with 3-D Printers”.

The researchers realized that with the explosion of 3D printers occurring at the time, it was likely there would be a wave of unidentifiable 3D prints that could miss recycling processes.

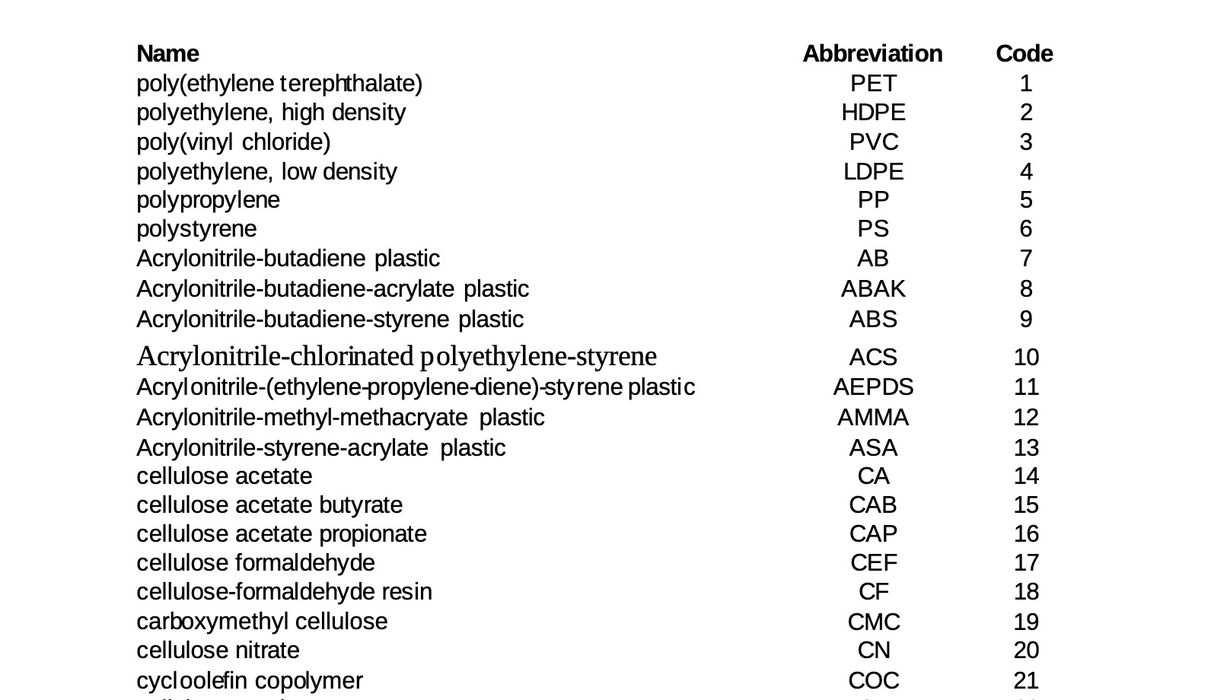

They wanted a coding system for a more comprehensive set of polymers that could be used into the future as the use of 3D printers increases. They found such a system in China, where there are 140 different identifying codes.

Their approach was to base a new, expanded system off of the China model. This starts with five basic classifications:

- Nonrecoverable Plastic – plastics that by law cannot be recycled in any way

- Recoverable Plastic – Plastics that can be recycled

- Rerecycled Plastic – Recycled plastic that is being reused to make a product

- Reworked Plastic – “Waste plastic from manufacturing that can be reworked into a product

- Repeatable Use Plastic – Plastic that can be used over and over again without needing to be thrown out or recycled

These symbols then contain an embedded code that specifically identifies the material. They developed a scheme to handle composite materials as well, where you would use a “+” sign to match materials. The scheme also handles other additives, such as fire retardants (“FR”). Reinforcing materials are handled by percentages. For example, PET-CB30 is PET material reinforced with 30% carbon black.

The list of specific material codes is very long, I believe over 200 in total. Every conceivable 3D print material I’ve ever encountered could be encoded with this list and the syntax described above.

The paper also describes OpenSCAD code for generating these symbols, demonstrating how straightforward it could be to implement this scheme.

This is a very intriguing concept that probably should be adopted, but that’s going to require an enormous educational and marketing effort to many people and companies.

But we should do it anyway.

Via Academia