There’s an increasing number of “high speed” FFF 3D printers coming onto the market, but what specific features should you be looking for?

For over a decade typical desktop 3D printers would print at a speed of something between 40-80mm/s, and there really wasn’t much difference speedwise between products.

Now, due to advances in firmware to compensate for the vibration generated during high speed 3D printing, we now see a number of “high speed” 3D printers arriving on the market, some with incredibly low prices.

How are these devices built to achieve high speeds? What features should one look for when choosing a high speed 3D printer? What does “high speed” even mean?

The Definition of High Speed FFF 3D Printing

Let’s tackle the definition first: “high speed”. This is a phrase increasingly used in marketing by 3D printer manufacturers, and it’s less informative than you might first think. It implies that a machine is “fast”, and that may be true. But the real question is, “how fast”?

Honestly, the only thing you can learn from seeing the words “high speed” is that the machine likely is able to 3D print at speeds higher than 80-100mm/s. Yes, that’s “high speed” in that it is a bit faster than traditional FFF 3D printers.

However, in practice there are two speeds: the “maximum possible speed”, and a “practical everyday speed”. For example, a machine might be touted as being able to print at 250mm/s, which is reasonably fast. However, the print profiles might suggest a more safe 150mm/s. In other words, the practical speed of a machine is usually somewhat less than its maximum speed.

Unfortunately vendors often tell you the maximum speed and don’t mention the practical speed. When you see the phrase “up to”, it means something.

I’ve also seen high speed FFF machines vary in speed. Some high speed desktop 3D printers run at 150mm/s, while others run at “up to” 600mm/s. That’s a factor of four difference, which is significant. I believe the industry really hasn’t landed on proper terminology for these speeds.

The bottom line here is to look for the speed specification for practical printing, not the maximum speed specification and especially not the words “high speed”.

High Speed 3D Printing Frame

High speed 3D printers generate a great deal of vibration because they’ll be rapidly swinging the toolhead back and forth. This is most evident when laying down a flat surface, where the toolhead snaps quickly. Each time the direction of movement changes, there is a lot of momentum to deal with.

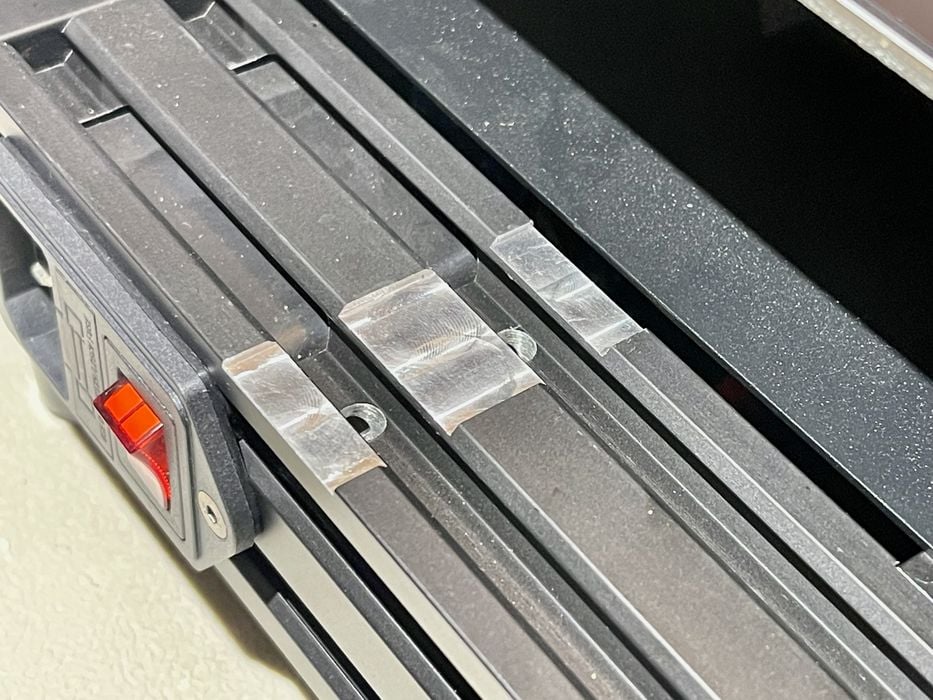

Some manufacturers overcome this with a “cube style” frame, which costs more to produce, while others attempt to make their gantry more strong with thicker metal extrusions.

To counteract vibrations, proper high speed machines use very robust metal extrusions for the machine frame. If you were to see a “high speed” machine with a flimsy-looking gantry, you could be in for some trouble.

High Speed 3D Printing Motion System

The most popular motion system style for desktop FFF 3D printers these days is the “i3”. In this mode, the Y-axis is the print bed itself, which moves forwards and backwards during printing. The X-axis holds the toolhead moves left and right, as well as up and down for the Z-axis.

The i3 style is simple to build and relatively inexpensive, hence its popularity. However, it has an issue when operating at high speeds.

Because the Y-axis shifts the entire build plate back and forth, it must move the print-in-progress as well. This adds momentum that must be compensated for. That’s challenging because the printer does not know the geometry of the model, which might be flapping around while being whipped forwards and backwards.

This effect can also affect adhesion, as the tipping forces on the model might cause it to come off the plate if not properly seated.

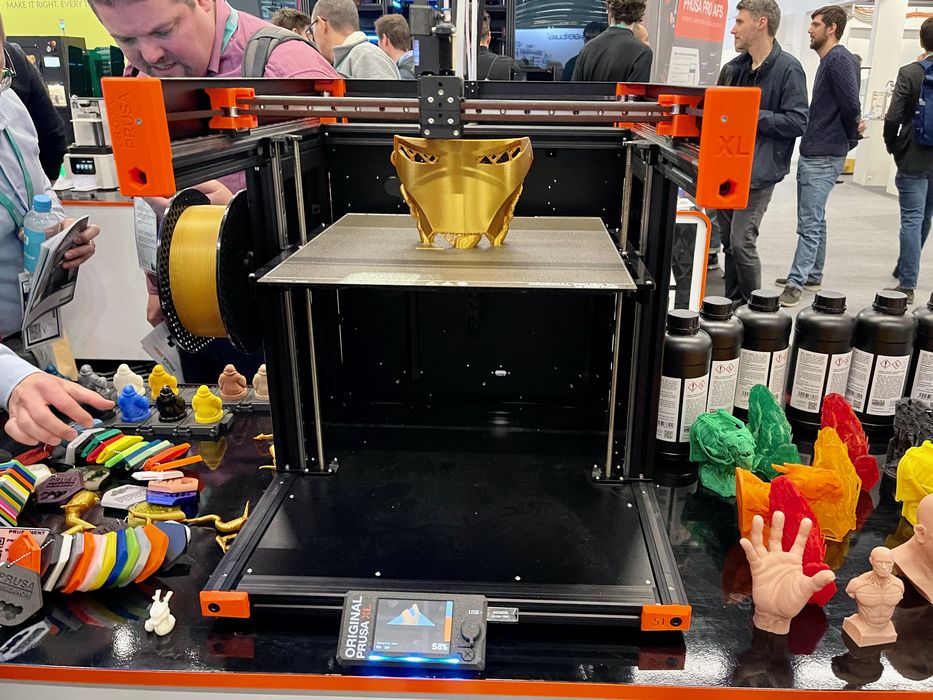

The solution is to use a CoreXY motion system, which keeps the print plate stable (except for the leisurely Z-axis movements). The CoreXY system is more complex and uses belts to move the toolhead.

Bottom line: CoreXY 3D printers are more likely to achieve the highest speeds than typical i3-style 3D printers.

High Speed 3D Printing Maximum Flow Rate

If one is printing a high speed, then the amount of material coming out of the nozzle must also be increased.

Extrusion and hot end systems are able to deliver a maximum flow rate, measured in cubic mm per second. Typical systems are not able to deliver enough material to keep up with the print speed, so enhanced extrusion and hot ends are usually required.

The extruder must be able to ram the filament down rapidly, and you’re looking for dual-geared arrangements. There is more force required to push down more filament. Single gear extruders are less likely to succeed at high speed.

As the material passes through the hot end, the heat will soften it before it emerges from the nozzle. But at higher speeds, the material has less time to soften. Sometimes raising the extrusion temperature can help, but this isn’t the best solution because the printer also operates at slower speeds during printing when hotter temperatures are not required.

The answer is a redesigned hot end that has a longer area of heat exposure. In other words, the filament moves faster but through a longer area. This maintains a proper amount of time for the material to soften.

The bottom line here is to ensure the extruder is upgraded and that the hot end is specialized for high speed 3D printing, and this can be judged by the maximum flow rate specification.

High Speed 3D Printing Cooling

What heats up must cool down. A high speed printer will finish a layer much faster than conventional 3D printers, and sometimes the layer hasn’t had time to properly solidify before the next high speed layer is coming down. To solve this problem high speed FFF 3D printers must have beefed up cooling systems.

You should look for higher speed fans and enhanced ducting designs that carry air all around the nozzle.

High Speed 3D Printing Firmware

Finally, we have the firmware, which is really the most important part of high speed 3D printing.

It’s easily possible to set the print speed to any ridiculous value in a slicer and try to get a 3D printer to run at that speed. Assuming you solve the flow rate, heating and cooling issues, there will still remain the vibration issue.

Here’s what happens: when the toolhead changes direction abruptly (something that happens constantly in a 3D print job), there is residual momentum in the toolhead. This is released by a wobble in the toolhead.

The result is what’s called “ringing”. It’s a repeated pattern seen in the print’s surface near corners where toolhead direction changed. Often it appears to be an “echo” of the corner.

Ringing increases with increased print speed, and eventually it gets to a point where it’s not just surface cosmetic effect, and begins to destroy the model’s geometry.

To overcome this effect, firmware was developed to compensate for the momentum shifts. Instead of simply changing direction sharply, the firmware plays with the stepper motor speeds to ensure correct motion during directional changes.

However, the firmware must be precisely calibrated on each machine before it can do this. Typically there’s a procedure that runs to measure how the toolhead moves during high speed wobbles. Once that’s done, the firmware can do its magic.

How do you know if a “high speed” 3D printer has this type of firmware? There are a few ways.

One way is if the manufacturer mentions “Klipper” as the firmware. Klipper introduced the concept of “input shaping”, a feature that does the compensation.

Recently the folks at Marlin integrated Ulendo’s momentum compensation software into the most recent releases. It’s possible for newer Marlin firmware-equipped 3D printers to have this feature as well. However, most 3D printers use older versions of Marlin that don’t have the feature so you can’t just check for “Marlin”. You have to see if the manufacturer mentions “input shaping”, “momentum compensation” or similar words with respect to their firmware. Some manufacturers have created their own firmware based on these two open source standards.

Choosing a High Speed 3D Printer

There will be many more high speed 3D printers hitting the market in the next year, and perhaps we’ll see a day when there won’t be any “slow speed” 3D printers available.

For now many 3D printer manufacturers are in catch-up mode, and have released machines with some — but not all — of the above features. They still call their machines “high speed”, but are they really?

It’s up to you to check out the specifications and make an appropriate decision.