Evolve Additive continues to make progress with their unusual STEP 3D printing process.

Evolve Additive, a spin off from Stratasys, has developed an industrial 3D printing process they call “Selective Thermoplastic Electrophotographic Process”, or “STEP”.

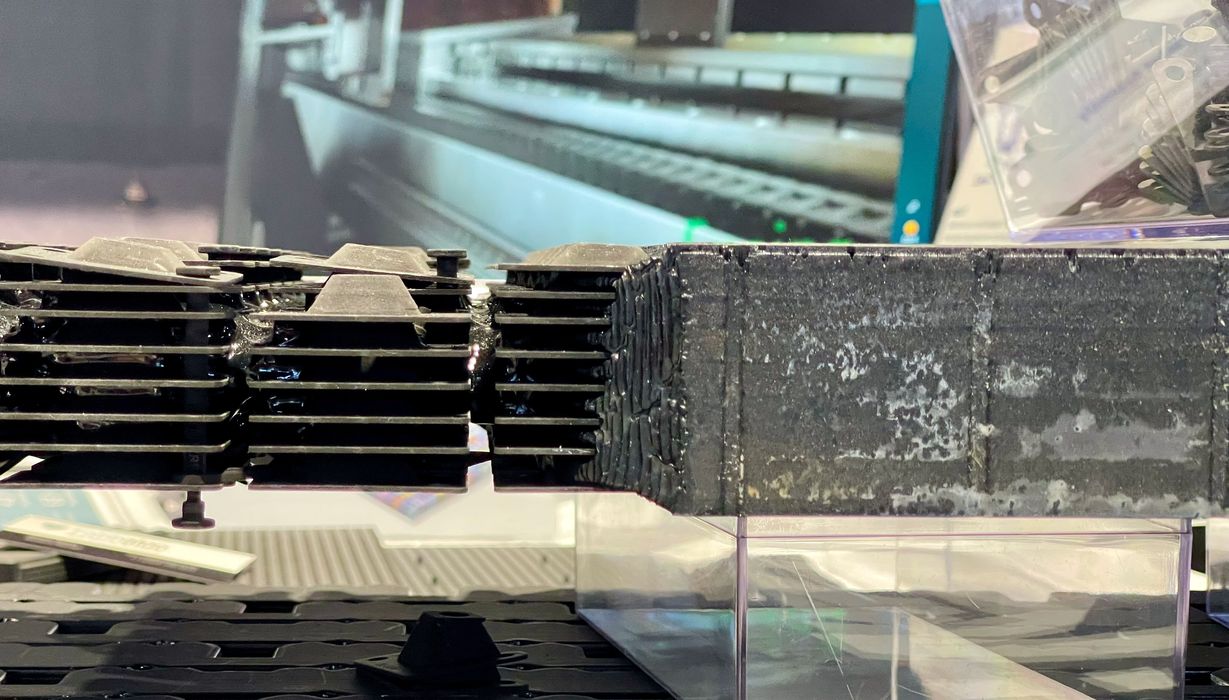

The process is very much like a photocopier: a rotating drum is selectively energized, allowing it to pick up loose powder on energized areas. The drum then rolls over along a planar surface, depositing the powder exactly where it was intended.

STEP involves multiple materials, however, and subsequent passes over a layer can deposit up to five different powders.

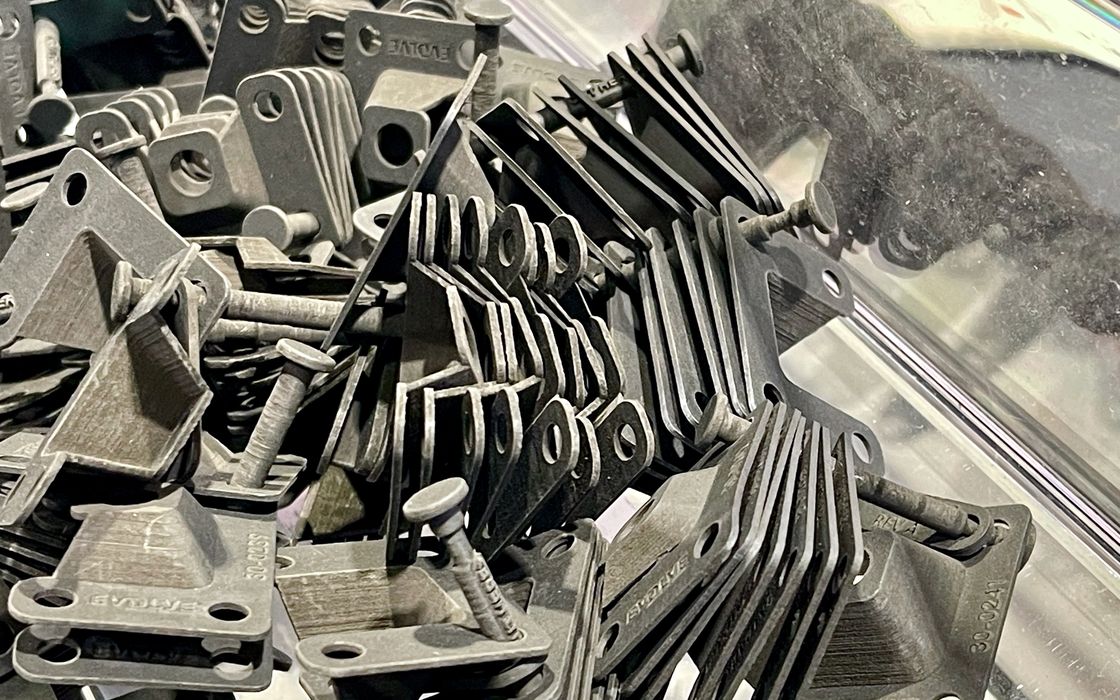

One of the powders will almost always be a removable support material. This allows a print job to contain many independent parts that are separated after printing by removing the support material.

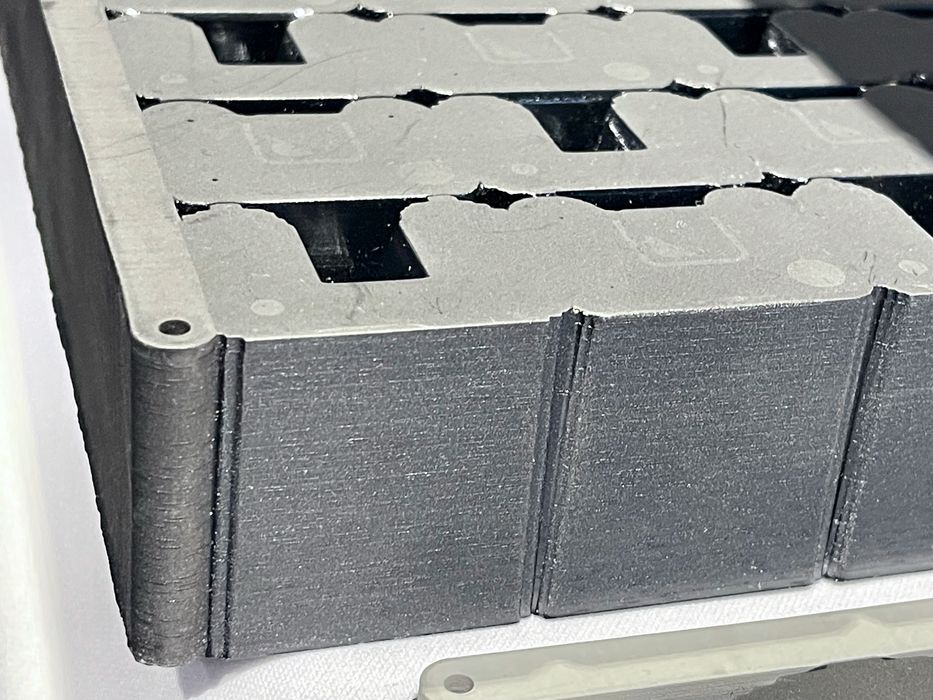

It’s also possible to print mechanical devices using STEP, much like one would do with print-in-place models on FFF or resin devices. However, in the STEP process the resolution is 600dpi, or 0.04mm. That allows for tiny gaps that can enable all manner of print-in-place designs.

STEP is also very fast. Evolve Additive told us they are able to complete and entire layer (600 x 300 x 100 mm) in only six seconds. Because of this, you could consider STEP as a production process, suitable for larger volumes of parts.

Currently the STEP system works with ABS material, but we’re told they’re working with SABIC, a major plastics provider, to enable PA11 (nylon) in the near future.

When we last heard from Evolve Additive they had installed their first commercial system. Since then they’ve installed a second commercial system at FATHOM, a well-known manufacturing service.

It also appears that Evolve Additive has organized a service to assist customers in using their system. As you can imagine, there are some differences in how best to design parts for use in STEP. The company can work with clients to provide education on how this is done, and also with their Evolve Creator software.

They also provide an “assessment program” to determine whether specific parts are suitable for STEP production. Part designs can be uploaded for analysis and even produced on their own equipment.

Finally, it seems there is an intention to build an e-commerce site for the company in the next few months, which presumably would be used for part production. This is an interesting move as it echoes the strategy of several other new 3D printer manufacturers that have chosen to not sell machines, but instead sell services.

Evolve Additive is one of several companies producing equipment that directly targets high volume production applications. Hopefully we’ll see industry begin to adopt these solutions in coming years.

Via Evolve Additive