We spoke to a scientist developing 3D printed batteries for future space missions.

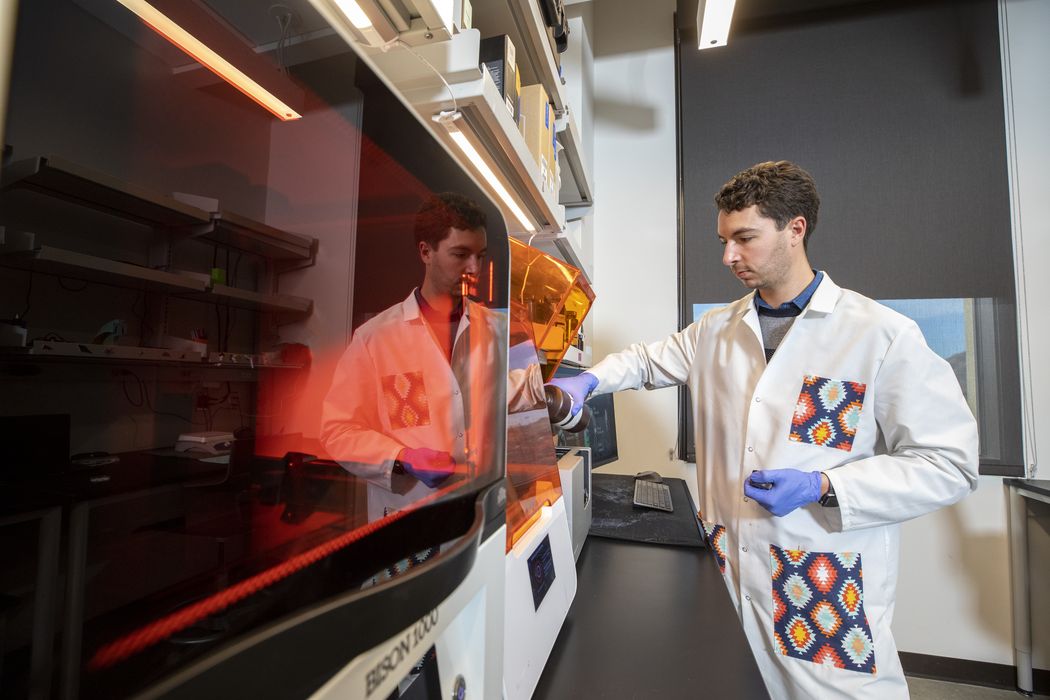

Alexis Maurel, Ph.D. is a Fulbright France Scholar and Postdoctoral Researcher at the University of Texas El Paso. He’s part of a key research project that intends to develop a method to 3D print rechargeable batteries made from local materials — on the Moon and beyond.

We asked Maurel some questions to learn more about the project.

Fabbaloo: Our readers are most familiar with 3D printing mechanical objects, but how is it that a battery can be 3D printed?

Alexis Maurel: A classical battery is composed of different components: two electrodes called the anode and cathode, a separator, an electrolyte, and two current collectors. All these components can be printed by adding active species (electrochemically active) within the material feedstock directly (filament for FDM, photocurable resin for SLA, ink for DIW). By printing these feedstock materials, shape-conformable battery components can be printed separately or together in a single-print thanks to multi-material 3D printers.

Fabbaloo: What exactly is the advantage of a 3D printed battery?

Alexis Maurel: Thanks to 3D printing, the manufacturing of shape-conformable and structural batteries, tailored for a specific application, is now possible. This would allow to maximize the energy storage capability of the final application by taking advantage of the dead-space and volume. Moreover, 3D printed batteries with interdigitated and intricate geometries of the electrodes would also pave the way towards batteries with enhanced specific surface area, ion diffusion and thus power performances.

Fabbaloo: The concept of 3D printing batteries on the Moon or Mars with local materials would certainly save transport costs, but what materials are present on these worlds that would be usable for battery printing? Are all the necessary materials present? What approach has your team been using to 3D print batteries? What 3D printing process and equipment are used? Or are you developing your own systems?

Alexis Maurel: While lithium-ion batteries are widely being used on Earth, due to the poor availability of lithium on the Moon and Mars, our team is rather targeting another battery chemistry called Sodium-ion. Precursors materials required to produced sodium-ion battery materials have been identified as part of this project. Unfortunately, not all necessary materials for the different components are present, but the idea is rather to maximize the use of In Situ Resource Utilization (ISRU) materials, available and extractable from the regolith or cargo and food packaging brought from the astronauts. Our team is currently focusing this work on 3D printing (vat photopolymerization and material extrusion of inks and filaments) manufacturing technique as it could help astronauts to manufacture batteries on-demand.

Fabbaloo: Are there concerns about the environments where this 3D printing would take place? The Moon and Mars have very different “weather” than here on Earth, so how must you adapt the process to function properly?

Alexis Maurel: In order to adapt to the weather constraints, the implementation of radiation shielding and other thermal regulation systems surrounding the 3D printed battery are being investigated.

Fabbaloo: 3D printing on other worlds would most likely involve automatic production. What steps have you taken towards automating the production process, or are we too early to consider that aspect?

Alexis Maurel: The first step of the project was of course focused on the material feedstocks preparation and 3D printing of independents components to ensure and test their respective electrochemical performances. Towards the automatic production of a complete functional battery in a single step, the team is now leveraging multi-material 3D printing systems.

Fabbaloo: If you solve the challenge of 3D printing batteries on these other worlds, could the same technology breakthroughs lead to enhanced battery production or function here on Earth?

Alexis Maurel: Yes, of course, and this is actually one of the main goals that we are pursuing. Our team at the University of Texas at El Paso has been focusing on 3D printing of lithium-ion batteries since 2017 for Earth application. Promising results on the topic led our team to enter in discussion with NASA and other partners to pursue this exciting topic of 3D printing of batteries from lunar and martian regolith.

Fabbaloo: At the point your technology is sufficiently mature, it’s presumably to be tested on the Moon. When do you anticipate that could happen, and what needs to take place before then?

Alexis Maurel: For now, this research is done at the laboratory scale and still needs further improvement before being tested on the Moon. It is unfortunately too soon to anticipate a date.

Fabbaloo: How will you feel when lunar testing takes place? Do you hope to travel there to oversee battery production in the distant future?

Alexis Maurel: Hopefully I will be able to see it in my lifetime. Who knows? This will be like a dream coming true. I would definitely love to catch a rocket and supervise this Lunar 3D printed batteries production!

Via UTEP