The TATAMI ReFAB PROJECT received the second prize award from the SaloneSatellite organizers.

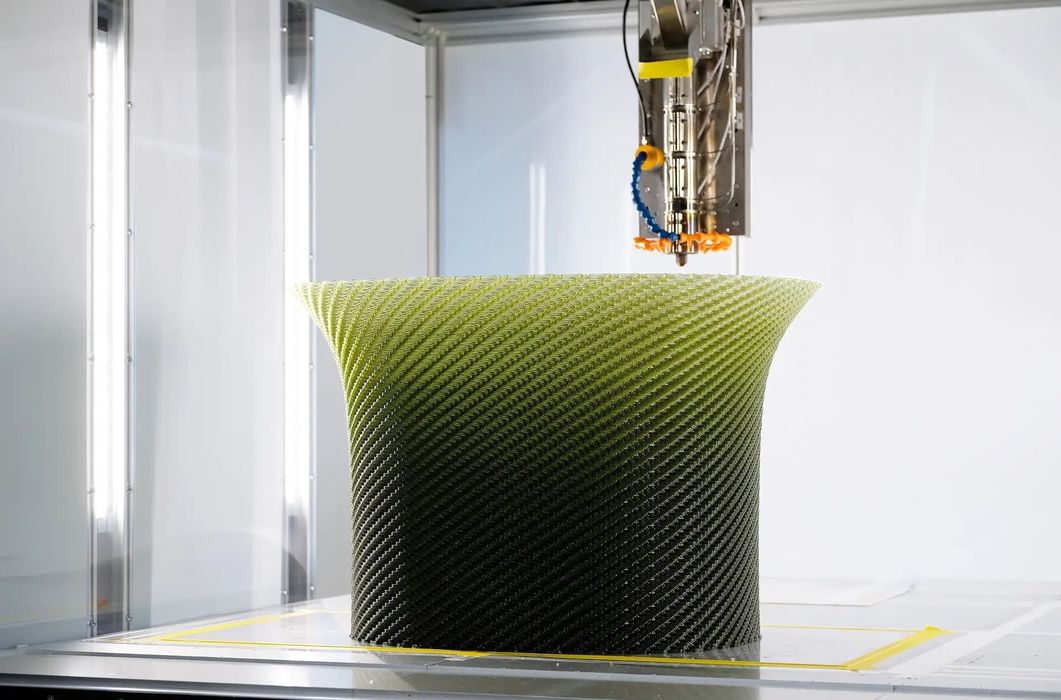

ExtraBold, a Japanese manufacturer of large format extrusion 3D printing systems, is supporting the manufacturing and material development of 3D printed furniture exhibited at Salone del Mobile 2023 in Milano. The TATAMI ReFAB PROJECT was created using ExtraBold Co., Ltd.’s large 3D additive manufacturing machine, the EXF-12, by design lab HONOKA.

Leveraging the work of several volunteer product designers, HONOKA exhibited a series of furniture in the Salone Satellite space. The studio developed its own materials by mixing biodegradable resin with Japanese discarded Tatami materials while using the large 3D printer from ExtraBold Inc. to reweave Tatami mats for modern living.

These pieces of furniture were originally developed using ExtaBold’s equipment and technology, using a mixture of rush, which is the raw material for discarded tatami mats, mixed with biodegradable resin (cellulose acetate). Tatami mats, which have been popular in Japan for a long time, are made from plants that are fragrant, pleasant to the touch, and have moisture conditioning and deodorizing properties.

However, due to changes in lifestyles, opportunities to touch tatami mats have decreased in recent years. The Tatami Refab Project is a project to reweave tatami mats into modern lifestyles. We created furniture with a new appeal by mixing used tatami mats and discarded raw materials with biodegradable resin (cellulose acetate). The purpose of this project is to transmit the appeal of tatami mats to the next generation.

In production, the waste rush provided by Ikehiko Corporation was pulverized, mixed with cellulose acetate at ExtraBold, and pelletized with a granulator for this project. This is a project that leverages a pellet-type 3D printer, the EXF-12, to create models using unique materials that are difficult to print with filament-type 3D printers.

The project was among the most appreciated at the SaloneSatellite exhibition area of the Salone del Mobile in Milano, where most experimental and innovative projects are found within the 750,000 square meters total exhibition surface of the fair. It received a second-prize award from the organizers. Other AM-related projects, seen below, included 3D printed furniture by designer Hsiang Han, 3D printed using Caracol LFAM technology, and other innovative products by EGOUNDESIGN.

SaloneSatellite was set up specifically to underpin the relationship between research, design and the industrial dimension, bringing to light those designers who distinguish themselves through the vocabulary of their own ideas. As an incentive to develop their career paths, the SaloneSatellite Award has assigned three cash prizes and two special mentions since 2010. Participation is free and it is up to the designers themselves to propose one of the projects they are showcasing at the special Salone del Mobile.Milano event for designers under 35.

Read the rest of this story at VoxelMatters