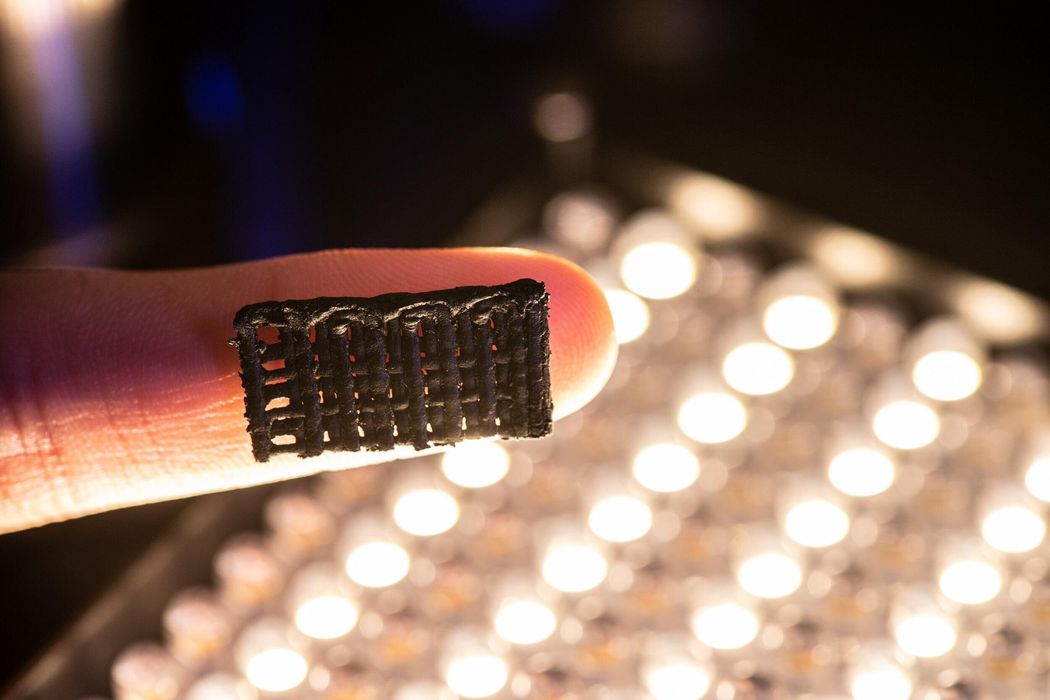

A groundbreaking new 3D printing material has been developed by a university student, opening up a world of possibilities in the industry.

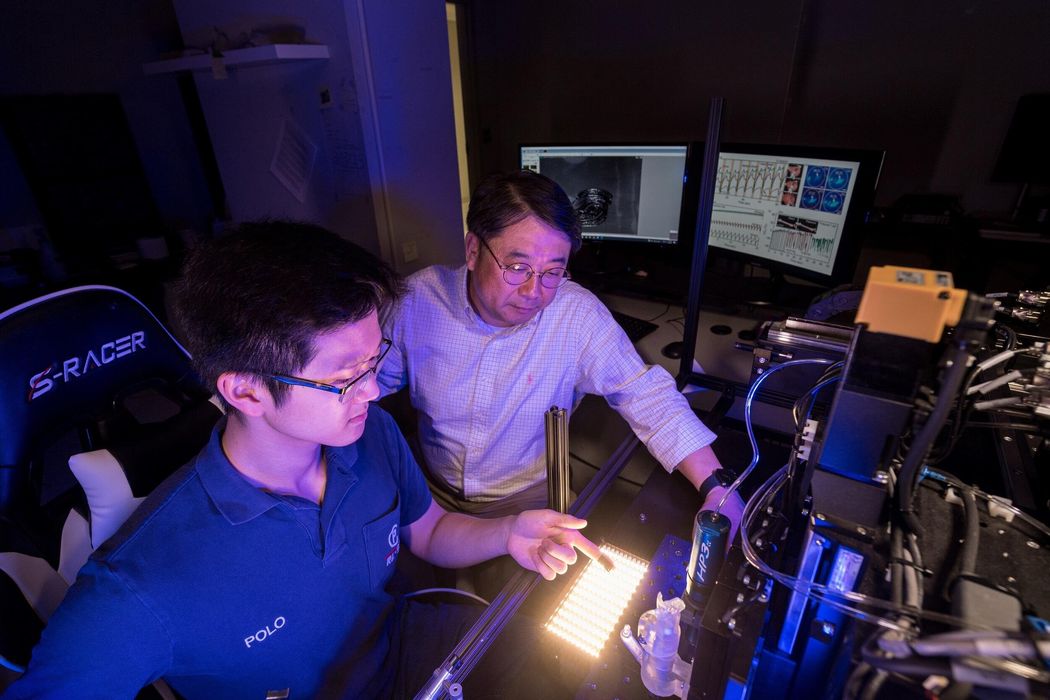

Andy Shar, from Virginia Commonwealth University’s College of Humanities and Sciences, was presented with the opportunity to develop this innovative material, and it seems he has succeeded. In an interview with Phys.org, Shar explains the composition and fabrication of the material:

“The material we discovered was a composite of silicone—polydimethylsiloxane, or PDMS—and we dispersed carbon nanotubes, or CNT, inside of that silicone, which is something that is kind of difficult to do. We used a pretty simple environmentally friendly technique to do it that can occur at room temperature. The fabrication process being easy allows it to be accessible to other people and maybe even companies who want to use it commercially.”

Material Properties and Potential Applications

What makes this material truly intriguing is the combination of three essential properties:

- Strength

- Flexibility

- Electrical conductivity

With these attributes, numerous applications can be envisioned for this technology. It could potentially allow the 3D printing of functional objects that bend without breaking.

Exploring Wearable Technologies and Biomedical Applications

Shar is particularly interested in the development of wearable applications, as he explained to Phys.org:

“eSkin technology is the future of wearable devices. So what Andy, Phillip, and I found is that 3D printable electronic skins can be useful for patients who suffer from skin diseases. Or we can have one that does health monitoring so that it’s a system where we can directly 3D-print into human organs. We can actually offer new therapeutic options. [As a physicist] I’m not going to use these directly with patients. However, this technology can be transferred to the operating room in the future. Then the patients can have the advantage to use this technology. That is our long-term goal for this project.

Let’s say we developed a 3D printable electronic device, or wearable flexible device. Now we want to make a connection from this technology into the spinal cord regeneration project. With spinal cord regeneration, there are always issues because of the structural complexity, right? So one of the therapeutic options is stem cell and electrical stimulation therapy. What Andy is doing is adding to it. As Andy mentioned, I am a pioneer of printing stem cells for spinal cord injury regeneration. So now Andy is combining these stem cell printing technologies and these flexible electronics.”

This development goes beyond traditional 3D printing applications and enters an entirely new class of possibilities. The potential uses for this novel material are limitless.

However, it’s important to note that this material is currently a research project, and commercialization will need to be pursued by 3D printing material producers. Given the expected utility of this material, it’s likely a licensing deal could be established to initiate that process.

Via Phys.org