Charles R. Goulding & Preeti Sulibhavi look at how 3D printing can produce BBQ accessories.

Summer is here and it is time to make memories at friendly backyard BBQs and picnics. Due to the global coronavirus pandemic, restaurant closures, and social distancing requirements, the home outdoor kitchen industry, which was already growing, skyrocketed. The global barbecue gill market is expected to grow at a compound annual rate of 4.5% from 2019 to 2025 to reach US$6.5B by 2025.

This has encouraged many homeowners to come up with their own culinary solutions that involve home outdoor kitchen equipment and barbecues.

While the supply chain was not initially prepared for the uptick in home outdoor kitchen demand, time and cost became limiting factors. This is where the 3D printing industry cooked up a plan to increase supply to meet this emerging demand.

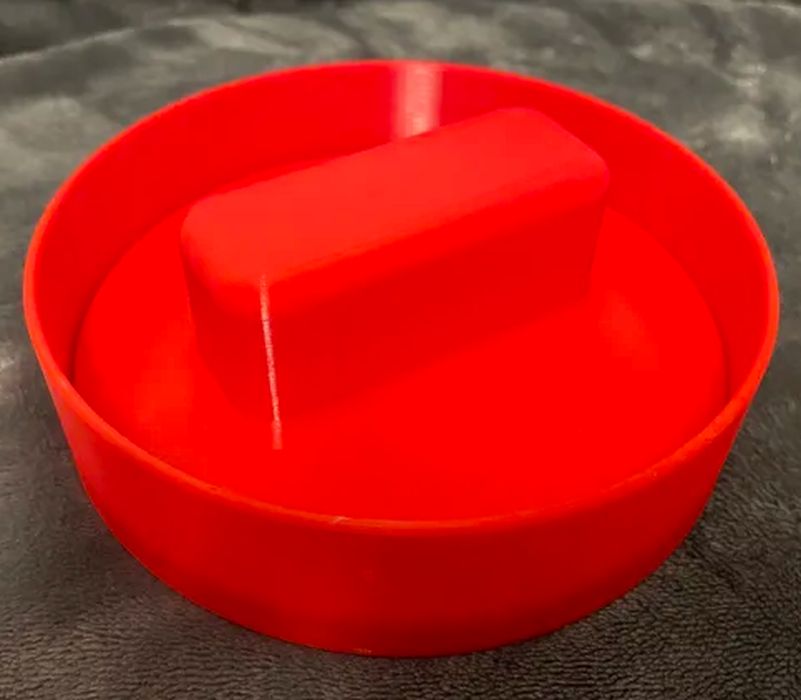

As Fabbaloo readers know, 3D printing can create objects that are both durable and lightweight, often at a fraction of the cost and time. Parts for home outdoor kitchen equipment can be produced in much less time and at far less cost. Barbecue equipment and accessories are no exception – as long as higher temperature materials are used!

R&D tax credit incentives are available for new and improved barbecue products and processes.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Fire Up the Grill!

What better way to come up with quick and easy BBQ solutions this summer than by using 3D printing.