Charles R. Goulding and Preeti Sulibhavi look at how 3D printing might affect the flooring market.

Some of the most under-stated components of a building are flooring and tiling. There are several reasons for this. One being the fact that they are often left for background aesthetic and are usually not given much thought to. Things are changing, thanks to help from 3D printing.

Flooring and 3D Printing

There has been a project, a decade in the making, where new floors can leave a noticeably smaller carbon footprint and use less concrete and steel. Flooring systems used in building construction are responsible for a large part of the greenhouse gases (GHS) emitted in the construction industry, which is responsible for one-third of worldwide GHG emissions.

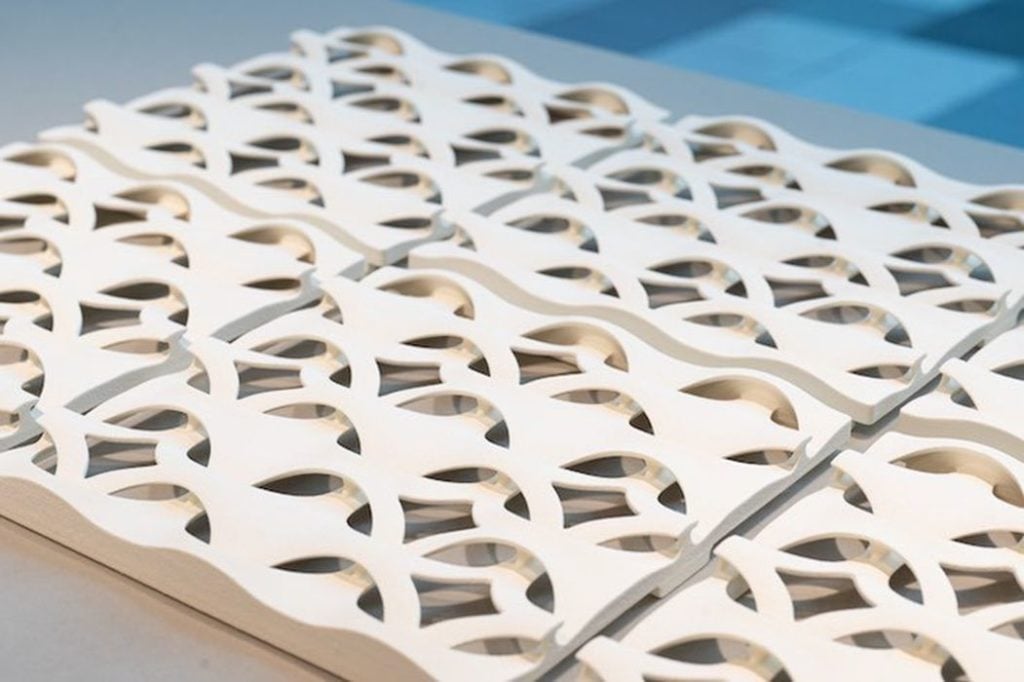

To better deal with the construction industry’s carbon emissions, a team of architects and engineers at ETH Zurich, a premier institution of higher education, who have developed a floor slab that requires only 30% concrete and 10% reinforcing steel of traditional floors. With building construction and operation leading to about 8% of global carbon emissions this is a great development, and it uses 3D printing technology to achieve these stellar results (as seen above).

Swiss researchers have gone further and have used 3D printing to fabricate funicular flooring systems to reduce concrete use as well. Due to the layered nature of 3D printed objects, they have tensile strengths lower than most materials in the construction industry, but their compression durability is very high.

A team of researchers from Block Research Group at the Institute of Technology in Architecture, of the ETH Zurich, has used 3D printing to create flooring using arch geometry where the weight is pressed onto the tip of the arch and then gets distributed throughout the whole floor slab/shape since it resolves the force into compressive stresses while simultaneously eliminating tensile stresses.

Tiling and 3D Printing

Netherlands-based Studio RAP is building an architectural structure that will integrate 3D printed ceramic tiles. Titled, “New Deft Blue,” the project combines clay 3D printing, computational design and artisanal glazing. The KUKA robotic arm is what is really behind the 3D printing process of the ceramic tiles as well as for concrete structures as well. Materials for the tiles are chosen for high durability and low maintenance. Even glazing 3D printed tiles works out more economically because 3D printing allows for “painting with shape” enabling smooth transitions between hues of blue and white that only 3D printing allows for.

The robotic arm allows for an algorithmic approach for 3D printing the design of tiles while considering specific manufacturing constraints all the while generating the desired tile geometry.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There are many reasons to consider advances in flooring and tiling. Some of the reasons include climate change and other global concerns, while others include manufacturing cost, efficiency and design constraints. Whatever the reasons for integrating 3D printing into flooring and tiling fabrication, the results are spectacular.