Researchers have developed a new metal alloy that is not only 3D printable, but also can withstand very extreme environments.

Researchers have developed a new metal alloy that is not only 3D printable, but also can withstand very extreme environments.

Introducing GRX-810: High Strength and Oxidation Resistance

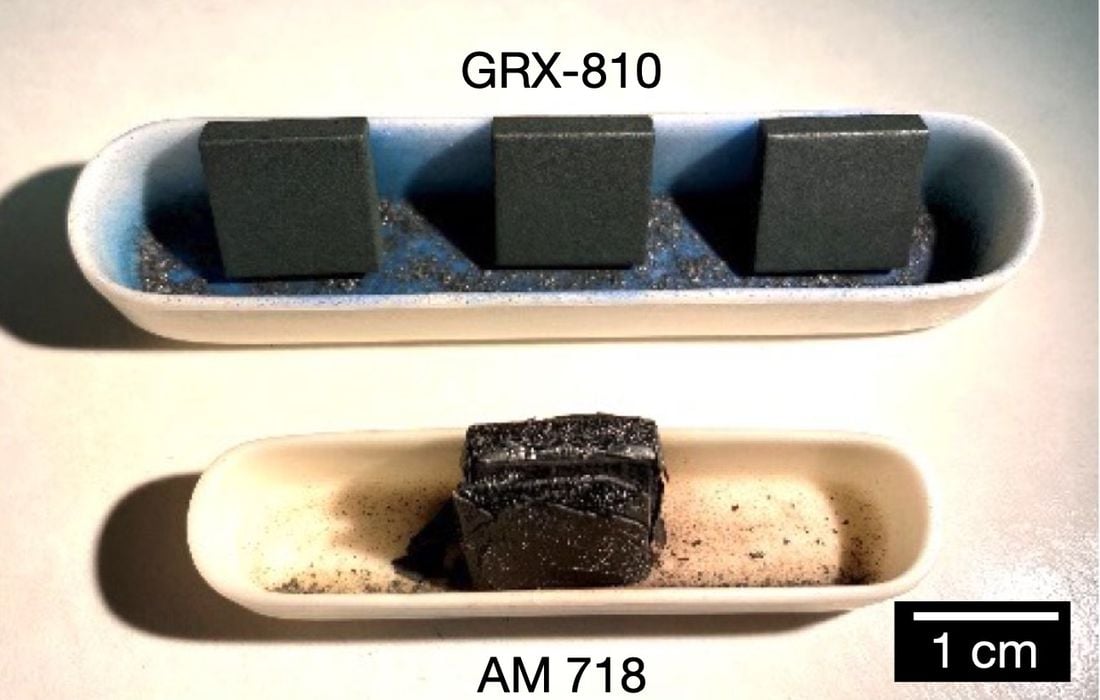

The new high entropy alloy, GRX-810, has apparently double the strength and significant oxidation resistance. It also shows double the oxidation resistance of typical Ni-based AM alloys. Oxygen is the villain of metals, as it bonds to surfaces (an example would be rust), potentially weakening the part.

Developing GRX-810: A Model-Driven Alloy Design Approach

How was this accomplished? The researchers explain:

“Here we develop a new oxide-dispersion-strengthened NiCoCr-based alloy using a model-driven alloy design approach and laser-based additive manufacturing. This oxide-dispersion-strengthened alloy, called GRX-810, uses laser powder bed fusion to disperse nanoscale Y2O3 particles throughout the microstructure without the use of resource-intensive processing steps such as mechanical or in situ alloying.”

High entropy metals are those with a mix of elements without a dominant single element. In this study, the researchers investigated NiCoCr alloys, which were shown by previous work to exhibit more advanced properties through slight adjustments with other substances. The researchers here put all the pieces together and came up with GRX-810.

Superior Creep Properties and Future Applications

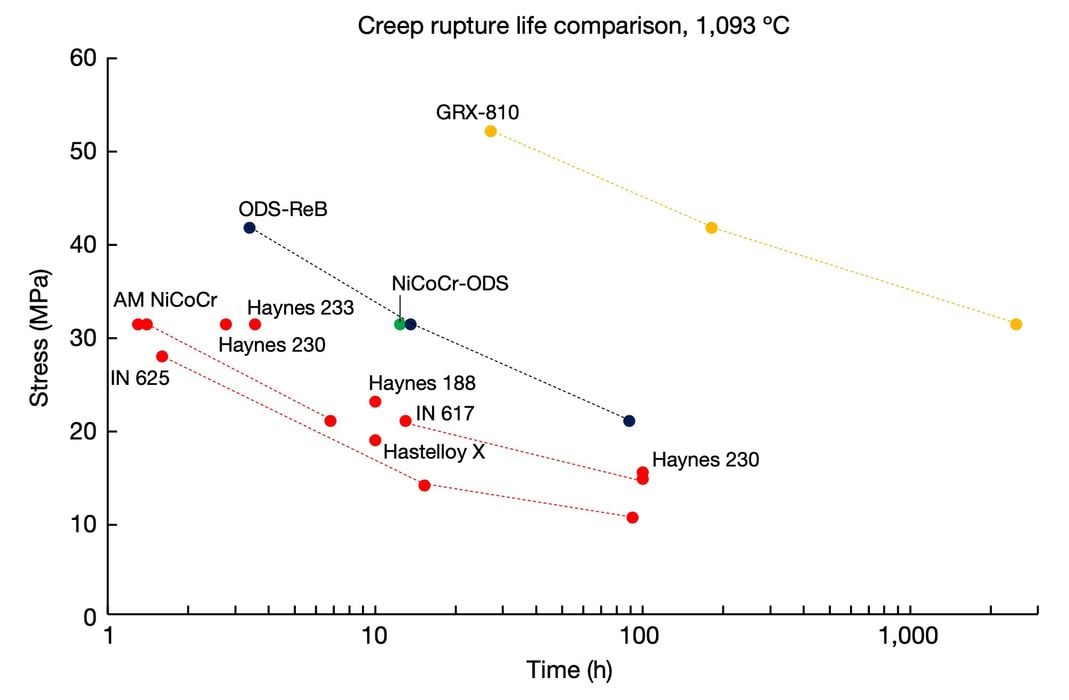

One of the interesting properties of GRX-810 is that it exhibits significantly superior creep properties. The chart above shows how it differs from other superalloys, and it’s not close.

While GRX-810 is the product of a research project, the use of the new material in production AM operations could be sooner than you might imagine. 3D Systems has been working with the NASA researchers on this material, and they have verified its properties when used in AM equipment. This material will eventually appear in many metal 3D printers, producing parts that will be able to function well in a much wider scope of environments.

The researchers used a computational modeling approach to devise the new superalloy, and it seems that approach was quite successful. Not only has a new alloy been produced, but a new method to make even more superalloys.

Via Nature