New research investigates the properties of high entropy alloys when used for additive manufacturing.

High entropy alloys are a material made from several different elements. Wikipedia defines them as:

“High-entropy alloys (HEAs) are alloys that are formed by mixing equal or relatively large proportions of (usually) five or more elements.”

They’re quite useful in certain situations where additional engineering properties are required. Whereas a single element might provide some of the requirements, it’s possible in some cases to gain additional properties by adding elements with those properties.

HEAs are often used in harsh environments, where one might expect material requirements to be more broad: it’s like customizing a material for an environment.

According to the researchers from Skoltech Center for Design, Manufacturing and Materials, most of the testing of these materials has been done with static setups. However, in real life these materials would undergo repeated stresses as they inevitably would be part of a mechanical device. The researchers say there has been very limited investigation of the fatigue behavior of HEAs.

That is precisely what their new paper, “Fatigue behavior of additive manufactured CrFeCoNi medium-entropy alloy”, in the upcoming May edition of the Journal of Alloys and Compounds seeks to answer.

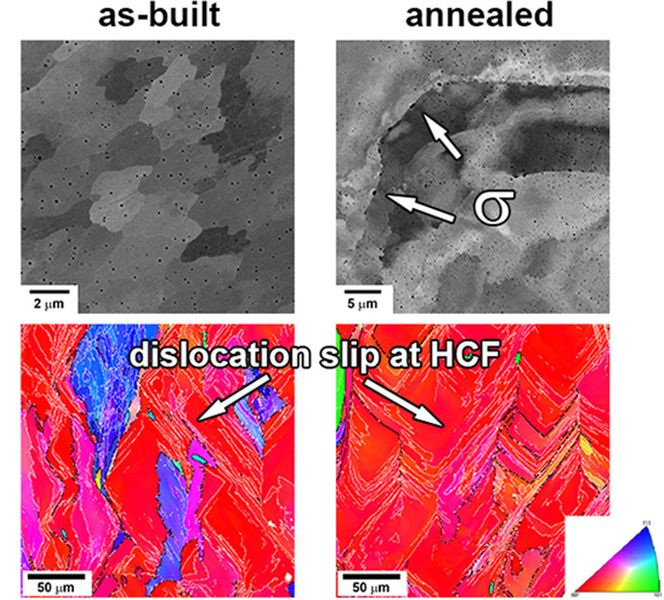

The researchers examined the behavior of a common HEA, CrFeCoNi (chromium, iron, cobalt, nickel) when subjected to a fatigue test at 25 Hz. The key here is that the samples tested were 3D printed using a PBF 3D printing process.

Their findings:

- Machining process plays a notable role in the fatigue properties of the printed CrFeCoNi alloy.

- Annealing decreases the yield strength of the printed CrFeCoNi alloy.

- Heat treatment does not affect the fatigue life of printed CrFeCoNi alloy in the HCF regime.

- Recrystallization process of the printed CrFeCoNi alloy occurs at 800°C.

- Secondary phases are observed in the printed CrFeCoNi alloy after annealing at 800°C.

While this specific research is clearly a niche area, it demonstrates the depth to which research has been investigating additive manufacturing processes. These research steps are absolutely required to broaden the knowledge of materials within the AM space.

Every step wider that breadth becomes means a few more applications can be lit up for additive manufacturing processes. Manufacturers keeping track of the research can be aware that their challenges using AM might now be overcome.

It’s easy to forget that we all know what we know; the familiar is easy, and the unknown should be avoided. Change can only occur when the door opens to new possibilities, and that’s exactly what’s happening here.

Via Science Direct