An entirely new 3D print application area has been developed: exposed fluids.

Researchers at the Lawrence Livermore National Laboratory have been experimenting with liquid surface tension effects when combined complex 3D printed lattice structures.

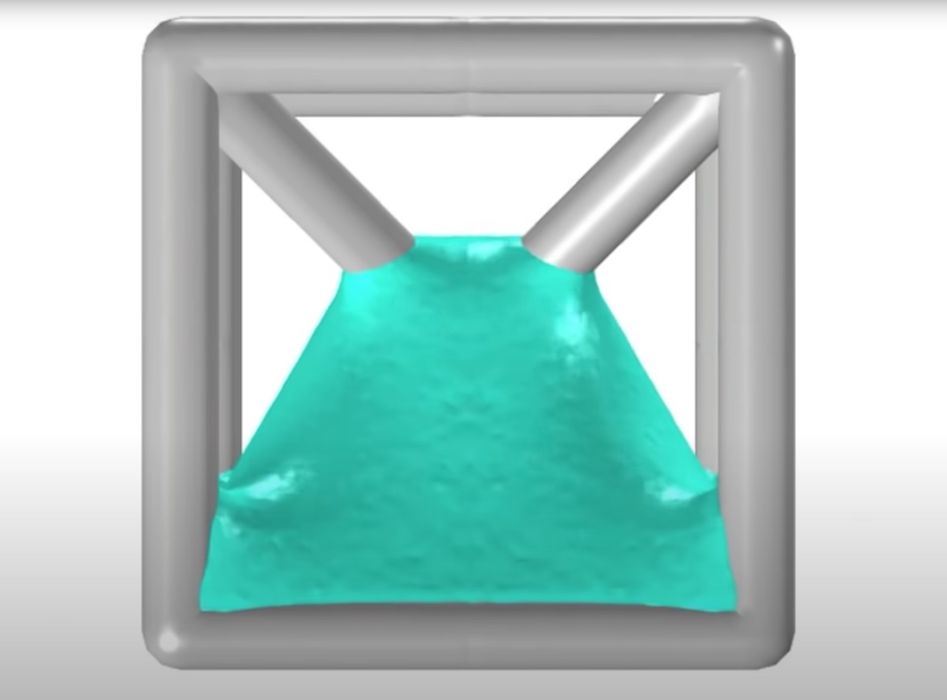

They’ve found that if the lattice is sufficiently small, fluids like water can “climb” up into the structure and remain stable.

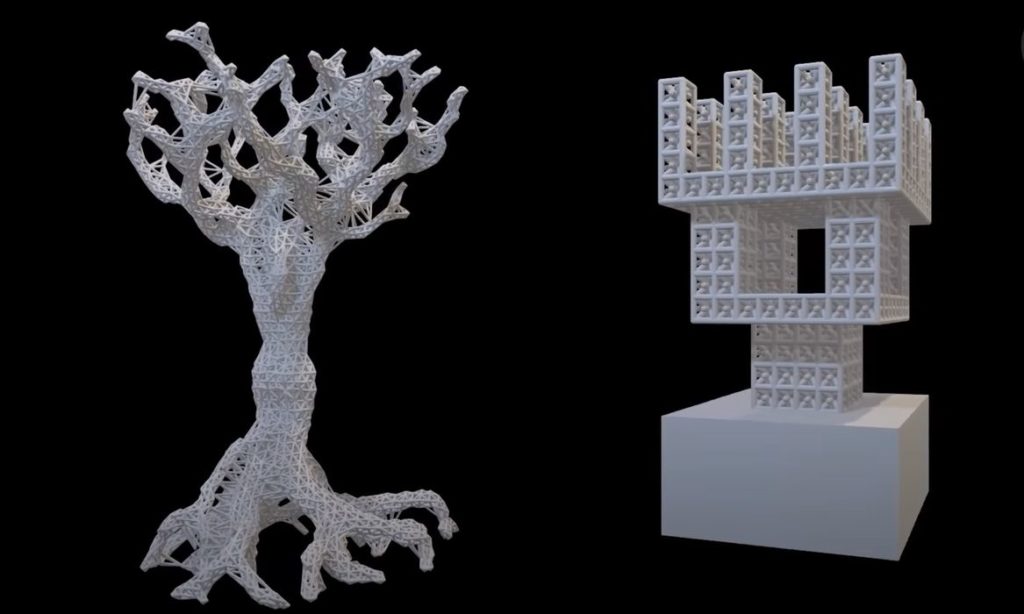

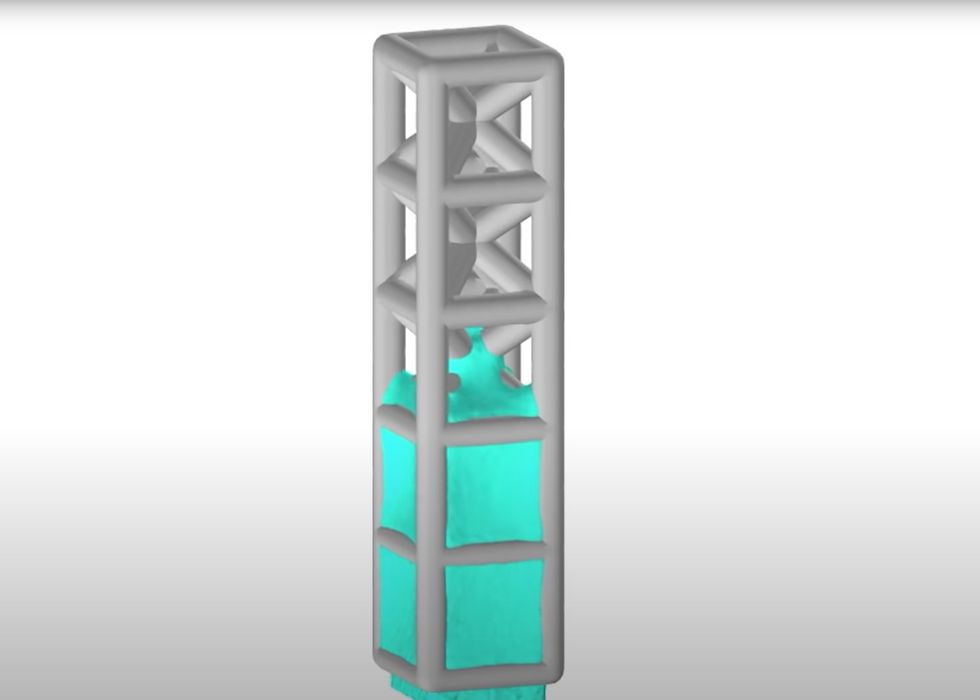

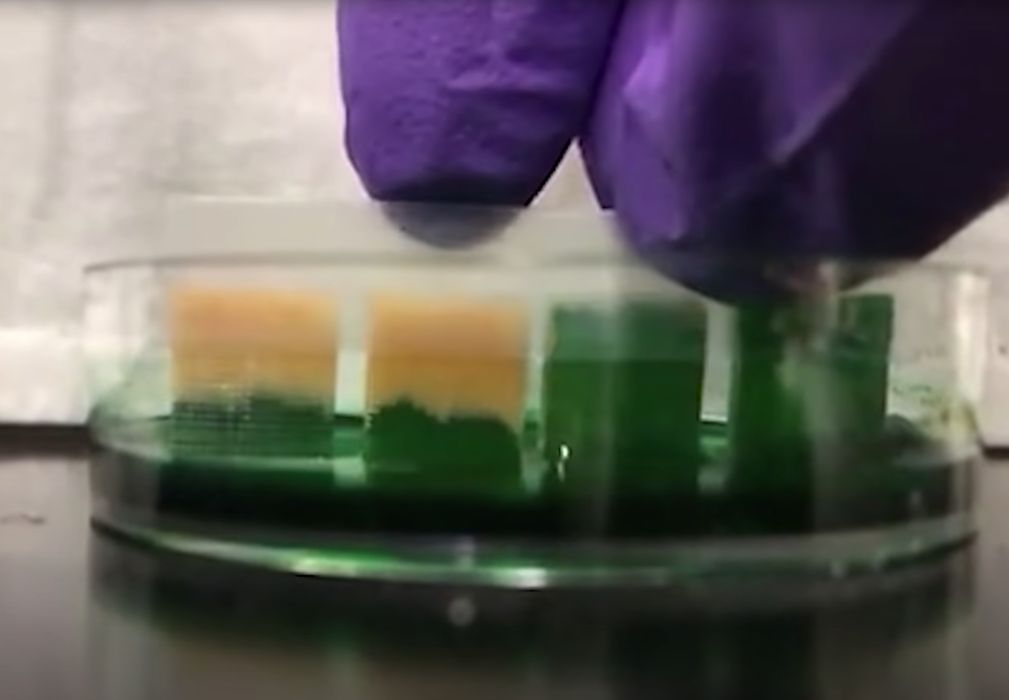

The researchers produced a small cube design with crossbeams that “holds” water when exposed to the fluid. By arranging a structure of such cubes, it’s then possible to design arbitrary geometries where the entire surface includes exposed fluids.

This capability offers the ability to create structures that maximize surface exposure. Typically fluids must be kept in containers, where only the top surface can be exposed to the air. However, with this technique the top, sides, bottom and other other structures can expose liquid to the air, and it all works due to surface tension.

This effect is used in nature: trees, for example, obtain water from the soil through capillary action: the surface tension of the water tends to draw the fluid through the tube up into the tree.

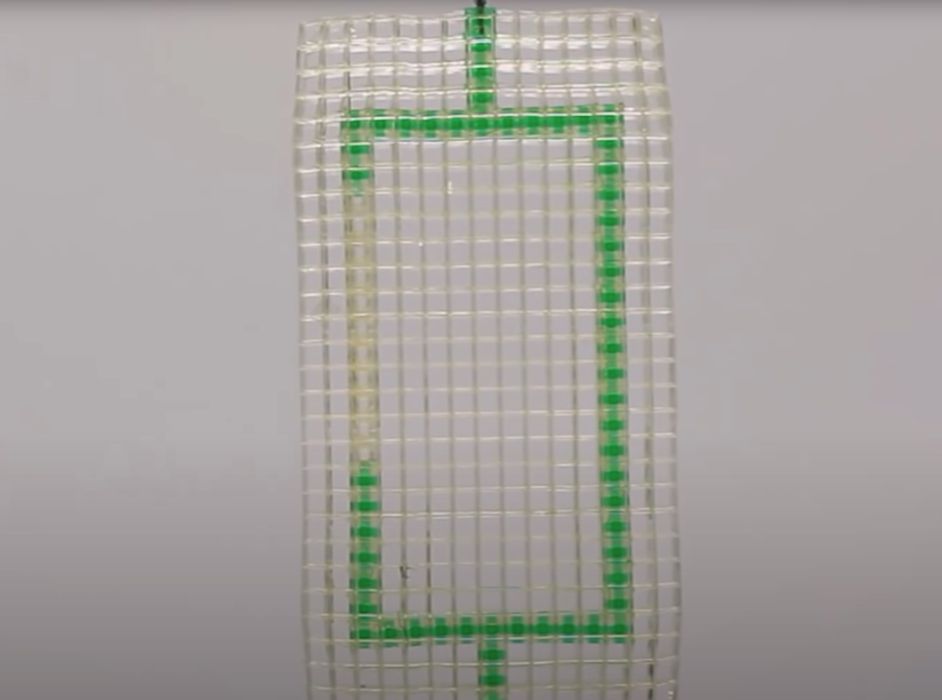

The researchers used an unspecified custom 3D printer to produce these small objects, likely some form of resin device. Unfortunately, in their video they showed multiple scenes of a common Ultimaker FFF 3D printer, which is almost certainly unable to produce objects of the required fine resolution.

The industrial applications of this could be tremendous, as there are many situations where fluid must be exposed to air.

For example, consider a radical re-design of a humidifier. Air would flow through a relatively small set of “fins” that would be “fluid-enabled”. The water would evaporate rapidly as air passes, putting humidity into the airflow. Fresh water would continue to be drawn upward into the fins as evaporation takes place. Because the water is directly exposed to the air, it’s likely the humidifier design could be smaller and more efficient.

Another application might be in space. In the researchers’ video they propose it could be used to more safely handle “loose” liquids in a weightless environment. I can imagine some kind of “drink cube” that you might impregnate with water from a dispenser. Then fluid could be drawn off when you’re thirsty.

The mind boggles when thinking of possible geometries and applications of this discovery. However, there are two technologies required to make it work: an ability to generate complex lattice structures in unusual geometries, and a 3D printer with material capable of producing items with the required resolution.

That and some imagination.

Please watch this astonishing video that shows how this works:

What applications do you see for this technology?

Via YouTube (Hat tip to Duann)