Charles R. Goulding and Preeti Sulibhavi look at developments in construction 3D print applications.

This post reviews four large cement, construction and alternative energy providers that are including construction 3D printing as one of their core applications.

Heidelberg Cement

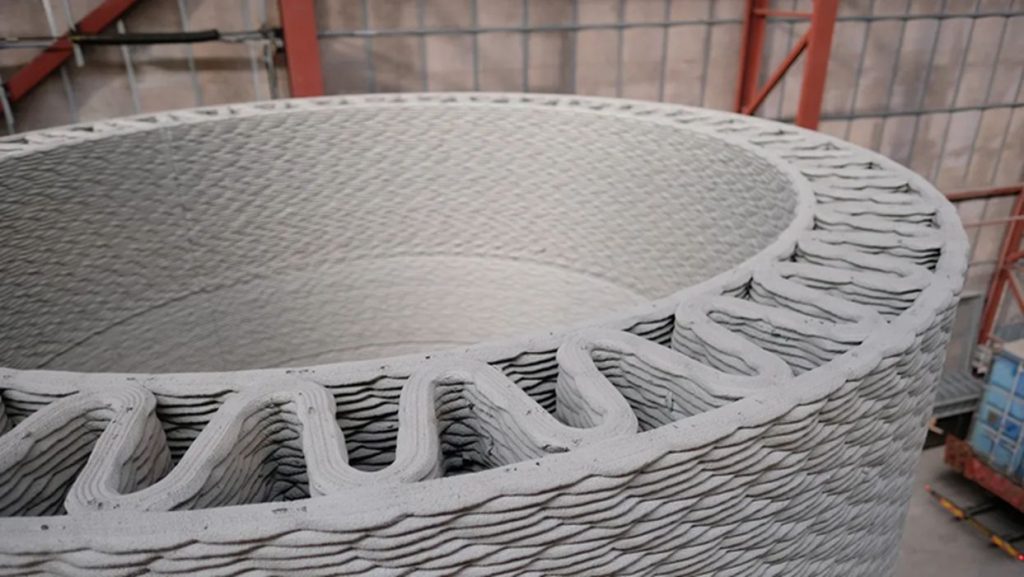

For fiscal year 2021, Heidelberg had US$21.2B in sales and over 51,000 employees, globally. Heidelberg is no stranger to 3D printing. In fact, since 2015, Heidelberg’s subsidiary, Italcementi, developed high tech concrete specially formulated for a variety of 3D printing technologies. Their materials can be mixed, pumped and extruded through a nozzle of any shape at the head of different 3D printer types. The product sets quickly and permits the laying of successive concrete layers.

In 2021, Heidelberg won a German Innovation Award for the first-ever 3D printed house. Heidelberg supplied the building materials and PERI provided the 3D print services. The printing material used was “i.tech 3D” printing mortar from HeidelbergCement. The project was supervised by experts from the Technical University of Munich and engineers from Schießl Gehlen Sodeikat. “With this production process, houses can be built faster, more economically and more sustainably. It also allows a highly individual design of living spaces,” stated the German building & elements category jury.

Cemex

Cemex in collaboration with COBOD is revolutionizing the construction industry by 3D printing homes. In July 2022, Cemex announced its investment in COBOD, the global leader in construction-grade 3D printers.

CEMEX and COBOD have been collaborating this past year to innovate in the 3D printing design space. Through this partnership, they recently introduced the first-ever 3D printing solution that utilizes conventional ready-mix concrete in the building process. The product can deliver significant savings versus traditional 3D printing construction methods and materials and has been implemented in several geographies.

Through this investment, CEMEX will strengthen its ability to use 3D printing technology and add another strategy to address housing needs. CEMEX and COBOD also intend to further develop innovative material solutions and building performance enhancements for 3D printing applications.

Current 3D printing construction methods rely on highly specialized and expensive mortars. CEMEX introduced a proprietary admixtures family called D.fab, which allows conventional concrete to be efficiently customized for 3D printing construction. This admixtures innovation produces a more fluid and easier-to-pump concrete that facilitates a myriad of 3D printing applications. COBOD’s printers and expertise, in combination with the admixtures, make it possible to implement a more efficient process that requires less material and can utilize any concrete.

GE Renewable Energy

We have covered the GE split-up, however, there are more developments at GE Renewable Energy and they have to do with concrete. In 2020, GE Renewable, COBOD and Holcim partnered to develop 3D-printed concrete bases for huge wind turbines that reached up to 200 meters. This project, which is a multi-year innovation challenge will lower the Levelized Cost of Energy (LCOE) while optimizing construction costs. The three will set out to produce a wind turbine prototype with a printed pedestal and production-ready printer and materials range to scale up production when ready. Each industry giant brings their own expertise related to design, manufacturing and materials.

GE will focus on design, COBOD will focus on automation and robotics, and Holcim will develop the customized concrete material.

Holcim

LafargeHolcim employs over 70,000 employees in over 70 countries and has a portfolio that is equally balanced between developing and mature markets. Holcim is the global leader in building materials and solutions and is active in four business segments: cement, aggregates, ready-mix concrete and solutions & products.

Its sustainability benchmark is to lead the industry in reducing carbon emissions and shifting towards low-carbon construction.

In its R&D center in L’Isle d’Abeau near Lyon, LafargeHolcim teams have leveraged their scientific and technological expertise to design a range of experimental concrete mixes suitable for 3D printing. Holcim has developed and provided materials designed specifically for the creation of two different 3D printed structures.

- A load-bearing post printed by XtreeE and assembled by Fehr Architectural, with a height of 4 meters (about 13 feet), being used to support the playground roof of a middle school in Aix-en-Provence in France. This is the first 3D printed structural element to be marketed in Europe.

- A pavilion created on behalf of the Ile-de-France regional authority using a revolutionary design, the brainchild of a collaborative project partnering XtreeE, Dassault Systèmes, ABB and LafargeHolcim.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Having these industry giants put their full support behind 3D printing will drive the global expansion of 3D cement construction applications for buildings and infrastructure. Applications include the Ukraine rebuild, global housing and the US programs for infrastructure and clean energy under the Inflation Reduction Act (IRA).