New Digital Source platform enables manufacturer-certified parts to be licensed and 3D printed on demand.

It’s been a promise of 3D printing almost from its inception: replace your physical inventory with a digital one to produce parts only as they’re needed. Save space, save maintenance, save time: what’s not to like? Of course, like so many technological promises, the lag between marketing hype and reality has been considerable.

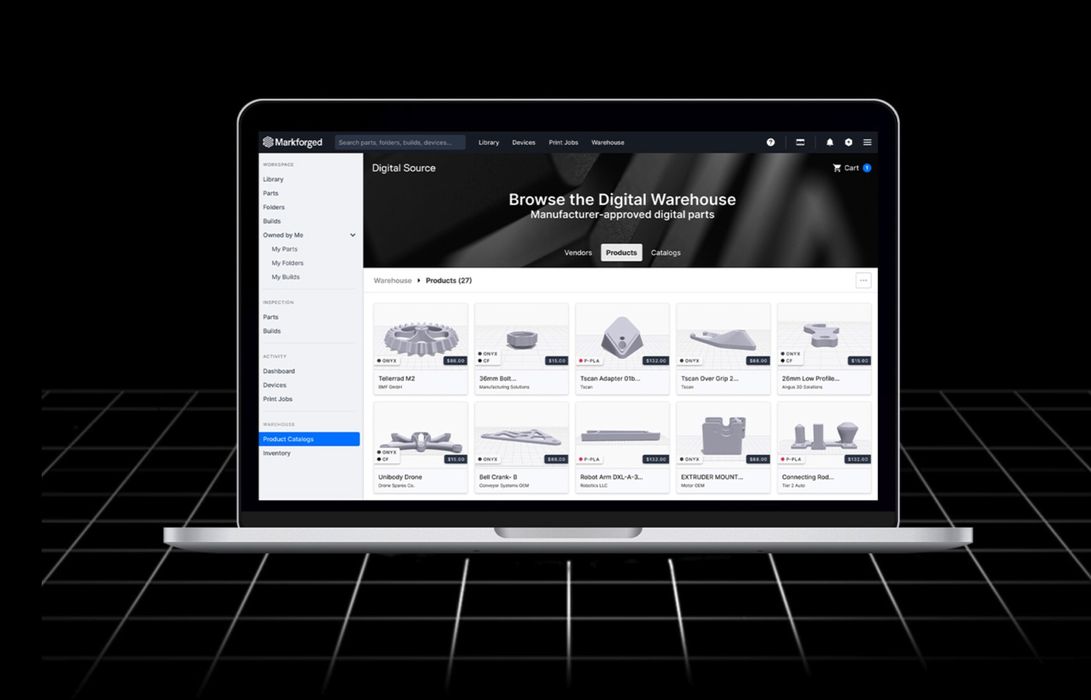

Fortunately, the dream of digital warehouses may finally be coming to pass with the announcement of Markforged’s Digital Source, an on-demand parts platform designed to enable the secure licensing and 3D printing of manufacturer-certified parts. Rather than shipping physical replacements, original equipment manufacturers (OEMs) can share their IP on the Digital Source platform so that their customers can print their own parts as needed.

Engineering.com sat down with Tripp Burd, Markforged’s director of new platforms, to learn more.

ENGINEERING.COM: So, the idea is that Digital Source allows OEMs to license their digital part designs to customers, distributors and contract manufacturers. Can you explain how that process works?

**BURD:**Well, the basic idea has been around a long time: it’s a folder of digital parts. The advantage of our approach is that you don’t lose control or visibility of a file after you share it.Typically, once you share a digital file, you lose control of it: the part can be reverse engineered, copied or modified. The internal settings can be changed in a way that no longer allows OEMs confidence that the part will be produced as intended.

With Digital Source, the OEMs can define a price for the part, as well as critical requirements and intervals—for example, a single-part license so you can print it once and then the file self-destructs. It’s a closed feedback loop, so the customer or the OEM can make sure the printer is up to date, the correct material is loaded and that the part is subjected to the right tests once it’s produced.

At the moment, we have a series of checks built into the hardware and software that can inspect the system the file is going to, but the end goal is to ensure compliance with other requirements, like post processing. So, if a part needs some post processing, I need to be able to ensure that the facility that will be printing it has those capabilities. And, as the OEM, I can get scanned data back in real time to show the part was created successfully and that it meets my tolerances and my customer’s requirements.

That’s what really differentiates this from other digital inventory platforms where, once the file reaches its destination, you lose all visibility into what happens to it.

Can you give us an example of how OEMs can use Digital Source?

Sure. There’s a machine builder in Germany called BMF that makes automated sandblasting cabinets which produce an extremely high-quality surface finish without a lot of the manual labor involved with traditional metal finishing. They’ve got hundreds of machines scattered around the world and dozens of parts for the internal mechanisms are printed on Markforged printers. Given that it’s a media blasting cabinet, the components get torn up and need to be changed every few months.

So, in their case, they were traditionally printing all of the spare parts and stocking them internally. If one of their customers has downtime, they call BMF and have the parts shipped out, which can take a week or more. Now, they’ve taken to bundling Markforged printers along with their hardware and, with Digital Source, they’re able to share secure catalogs of spare parts—so the printer itself is like a spare parts kit.

And the advantage is that these new users don’t have to go shopping for 3D printing or know anything about design for additive manufacturing. All they have to do is keep the machine on and loaded appropriately, and when they need spare parts, they just access the catalog that BMF has shared. That means cheaper parts for the customer, better service, better margins and less overhead for BMF, so everybody wins.

It sounds like this would give OEMs a way to expand their footprint without having to build a whole factory in a new market. Is that right?

Absolutely. This is a digital supply chain tool: we have customers that are expanding globally, so they’re bringing on distributors and service providers. Typically, that means manufacturing locally, so you’re dealing with customs and tariffs and lead times. Instead, you can push all of that distribution digitally because you can push jobs to third-party print services.

So, if I need a component but it’s larger than the build envelope in the printer I have, I can send it out to a supplier and use their capacity instead. Or you might have one machine for on-demand spares, but when you need to make a production run to meet peak orders, you can route jobs to that extra capacity.

Read the rest of this story at ENGINEERING.com