The 2022 Wohlers report on Additive Manufacturing has been released.

Each year Terry Wohlers what is most certainly the most detailed assessment of the current state of technology for additive manufacturing available anywhere. Wohlers is a long time analyst and consultant in the space, and his reports have become a standard piece of intelligence for many companies and professionals inside and outside of the 3D print world.

This year is the first release that occurs under the new ownership of Wohlers Associates, which was acquired by ASTM International last fall.

If you believe this may compromise the quality of the report, you’d be wrong, because the terms of the acquisition have left Wohlers Associates to continue on as they have been for decades. The report will certainly be at the same or higher levels as before.

What will you find in the 2022 report? There’s plenty of statistics that indicate the current growth trends and usage of the technology by industry. This is critical information for many:

- 3D printer manufacturers can understand the market they are selling into

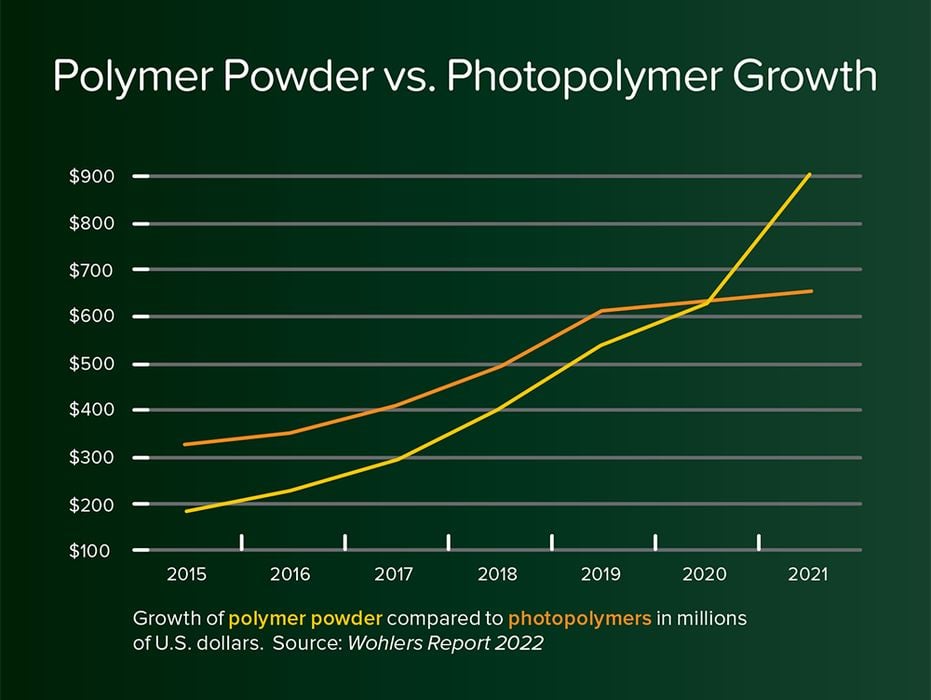

- Materials providers can observe trends in what types of materials are growing at the fastest rate

- Manufacturers can understand how their competitors might be making use of the technology

The past two years have been problematic in a number of ways, with the pandemic causing havoc in many industries. Some of these industries temporarily lowered their use of 3D printing technology, but according to Wohlers, the upward trends have resumed. He explains:

“As expected, the industry has returned to a period of advancement and investment. This expansion cuts across aerospace, healthcare, automotive, consumer products, energy, and other sectors.”

According to the report, the AM market has grown by a very healthy 19.5% in 2021, which is far more than the growth of 7.5% in 2020, the year the pandemic commenced. It’s interesting to note that even in 2020, AM still managed a very positive growth statistic.

This is likely due to the “discovery” of the technology by manufacturers left in the cold when their overseas manufacturing supply chains broke down. For many companies the alternative was to obtain 3D print technology, some for the very first time, and perform their own part manufacturing.

Wohlers listed some “new and expanded features” in the latest report:

- Scaling AM into production

- Workforce development and sustainability

- Women in 3D Printing

- Ground-breaking R&D programs

- Reports from industry experts in 34 countries

- The future of AM

In all, there are 425 pages in the massive report.

One extremely interesting finding already made public from the report is that the use of polymer powder material has now exceeded that of photopolymer materials for the first time. This could be due to the number of SLS production operations coming online, that finally outnumber the production SLA operations that have been around for years producing items like dental aligners. The SLS operations have clearly shifted from prototyping to production.

The report also covers corporate activities, as it includes details of 75 mergers, acquisitions and IPOs.

If you have a need to have a deeper understanding of the current state of additive technology, this is the report for you. It’s available for purchase at Wohlers’ site at a cost of US$595 for a digital copy.